|

|||||||

| RX-7 2nd Gen Specific (1986-92) RX-7 1986-92 Discussion including performance modifications and technical support sections. |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| RX-7 2nd Gen Specific (1986-92) RX-7 1986-92 Discussion including performance modifications and technical support sections. |

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Last time I checked, a good, name-brand, entry-level TIG was going for a minimum $2,000...

Wow, wish I had that kinda equipment just sitting around. If I had a TIG like that sitting around, there's a lot of other stuff I would be working on rather than something like this. ...but that's just me. -Ted |

|

|

|

|

|

#2 | |

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

Quote:

Though I'm with you Ted. Most people can't/don't weld cast aluminum due to unknowns in thickness, metal type, and other problems associated with cast aluminum. It can be done, but prep is a pain if the aluminum is not fantastic. I also think a top mount is an justifiable AIT cooling method for low to medium power levels (stock-300). For more power another setup can be used to better cool the charge; v-mount, front mount, h-mount, etc, etc, etc.

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group Last edited by vex; 03-17-2010 at 09:05 AM. |

|

|

|

|

|

|

#3 | ||

|

KTEC

Join Date: Jan 2009

Posts: 642

Rep Power: 0  |

Quote:

And no i havnt had it on a dyno. But I have used three different style intercooler set-ups on the stock turbo before this one (making this number 4). And from my own personal experience (my own set-ups and others), this is much better than a front mount. Most front mount "Ebay" intercoolers are poorly designed and hurt flow more than anything. look inside one and compare it to a well designed core and you'll see what i mean. Plus the widely used 2.5" piping hurts power more than it helps. 2.5" is MUCH to large for the stock turbo. again, most people also use a super large intercooler, further hurting the set-up. Now a correctly built V-mount will be better than what i did of course, but i dont see ANY front mount being better than a modified/aftermarket top-mount for the stock turbo. Remember, one 90* bend is equal to 5' of pipe. Now add up length of pipe and all the bends, and the big core up front wich your air has to force its way through. what does that equal? a turbo that has to work twice as hard to make give the same amount of pressure. and a motor that has to wait twice as long to recieve it... **also, if anyone was interested in me doing this to your top mount, PM me... thatnks for the idea. Quote:

and just to be clear, im not trying to battle it out with you. but you seem to have a little hater-ade in a lot of your posts. here and other places. never really see anything you like besides what you do... not open to new ideas??? myself personally... im tired of the same old, "just put a TII in it", "put a front mount", "get a GT35", ect. ect. ect.... FC's need a breath of new life. Everyone has the same set-up and the same 400 hp goal. ok i'll stop... im ranting a little here.

__________________

what I have: 1985 Gs:12a All motor Drag car - 1973 Rx2: Play car What I had: 93 Touring: TRADED - 91 Coupe: TRADED - 90 GTU: RHD - 88 10AE: SOLD - 87 Base: SOLD - 86 Base: SOLD - 1985 GSLSE - 85 Gsl: SOLD - 80 Gs: TRADED - 1972 Rx2 Last edited by sen2two; 03-17-2010 at 08:24 PM. |

||

|

|

|

|

|

#4 | |

|

destroy, rebuild, repeat

Join Date: Feb 2008

Location: Charleston, SC

Posts: 395

Rep Power: 18  |

Quote:

__________________

1993 RX-7 Touring MB, stockport 13B-REW, 9.4CR rotors, T04S 60-1/p-trim single turbo 1986 RX-7 Base project track beast |

|

|

|

|

|

|

#5 | ||

|

KTEC

Join Date: Jan 2009

Posts: 642

Rep Power: 0  |

Quote:

Quote:

__________________

what I have: 1985 Gs:12a All motor Drag car - 1973 Rx2: Play car What I had: 93 Touring: TRADED - 91 Coupe: TRADED - 90 GTU: RHD - 88 10AE: SOLD - 87 Base: SOLD - 86 Base: SOLD - 1985 GSLSE - 85 Gsl: SOLD - 80 Gs: TRADED - 1972 Rx2 |

||

|

|

|

|

|

#6 | |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Quote:

What you think of my opinion, well... I mention the difficulty in (TIG) welding cast aluminum, because... I guess you can liken it to welding cast iron, but most weldors will not usually bother TIGing steel / iron - most would either blast it with a MIG or just stick it. Due to the porous nature of the cast aluminum, TIGing this kinda material is not for the faint hearted or novice. Blowing holes through cast aluminum, especially of this thickness (thinness? Is that a word?) is very easy, unless you really know what you are doing - you make it sound like any Joe Schmoe off the street can do it? NO used shit - most expert weldors will agree that used welding equipment is a gamble. This does not get you a tank - more money to buy or rent one... Filling the tank with gas - more money... Cart - well, I guess you can lug the entire welder around if you got the muscles for it... http://www.millerwelds.com/products/tig/diversion_165/ The website lists it at a little over $1,600. Looks like Miller dropped the power on their entry-level TIG. Lincoln used to offer a TIG 175, but they don't list it on their website. Miller used to have a 180 TIG? http://news.thomasnet.com/fullstory/15631 But it looks like it got replaced by that 165. 20% rated duty cycle? Geez... Got bucks? Go ESAB... http://products.esabna.com/EN/home/a...ig_1500i2200i_ Back to the topic... Seriously... Not many of us can do such mods on their FC's like this. That includes me. That's my point. Now, if you're going to offer the modded throttle body, couplers, and pipes for like $100? I don't know why you're arguing about wrong pipe size and such? That's not my problem. If you're slapping on bad equipment on your car, it's your fault for doing so. For the other guy who's claiming an aftermarket top-mount IC is superior... Give me numbers. "Cool to the touch after a hard run" doesn't tell me jack shit. Sorry, I don't believe in butt dynos... I can make your car "more responsive" just by changing the pressure in your tires. Get the dyno numbers and we'll see how much of an advantage it is. Right now, you're just telling us it-just-feels-better? I'm just telling you to prove it. Call me hater or whatever, but I wanna see numbers. Sorry, I'm not into believing every Tom, Dick, and Harry's claims on the InTerNeTz... -Ted |

|

|

|

|

|

|

#7 | |

|

Test Whore - Admin

Join Date: Mar 2008

Location: Right Behind you son

Posts: 4,581

Rep Power: 10  |

Quote:

Yet all the credit is given to the CDI box..... I fricken hate that garbage. Show me a back to back dyno run on the same day, with the same map, and the same ambient temps then we'll talk. I say the same holds true for your 4 iterations of intercoolers. Yeah it's nice to be able to say, check it out, look what I did, it's so much more responsive. However, I want to see a back to back to back test of the stock TMIC, a FMIC with a REAL core, and this one. Then we'll actually know for sure. Yet all the credit is given to the CDI box..... I fricken hate that garbage. Show me a back to back dyno run on the same day, with the same map, and the same ambient temps then we'll talk. I say the same holds true for your 4 iterations of intercoolers. Yeah it's nice to be able to say, check it out, look what I did, it's so much more responsive. However, I want to see a back to back to back test of the stock TMIC, a FMIC with a REAL core, and this one. Then we'll actually know for sure.As for the, cold to the touch after an auto-x run....... show me some datalog's please. I can show mine and I'll tell you exactely what my AIT's were throughout the entire run as well Data= everything. I'll take one dyno run over a thousand ass dyno's anyday, the same goes for one test result vs a thousand expert opinions.

__________________

-The Angry Stig- DGRR 2009, 2011, 2012 & 2013 - Best FC DEALS GAP!! WOOHOOOO!!!!! 2015 Audi S4 - Samantha - Zero Brap S4 2004 RX8 - Jocelyn - 196rwhp, 19mpg fuel to noise converter 2000 Jeep Cherokee Sport - Wifey mobile - Now with 2.5" OME lift and 30" BFG AT KO's! So it begins 1998 Jeep Cherokee - 5 spd, 4" lift, 33" BFG's - Rotary Tow Vehicle 1988 'Vert - In progress 1988 FC Coupe - Gretchen -The attention whore BEAST! I'm a sick individual, what's wrong with you? I'm pure Evil I'm still insane, in the best possible way. I think Brian's idea of romance is using lube. Your rage caused the meteor strike in Russia. The Antichrist would be proud of his minion. You win with your thread. Most everything It's a truck with a steel gate on the back. Just a statement of fact Motec M820, AIM dash, ported 13B-RE Cosmo, 6-spd trans, 4.3 Torsen, custom twin wg fully divided mani, Custom 4" split into 2x 3" exhaust, Custom HMIC, Custom custom custom custom I like to welder stuff.... No Bolt-ons allowed. Dyno'ed @ Speed1 Tuned by me - 405rwhp on WG.... WM50 cuming soon. -Angry Motherf*cker Mode ENGAGED- |

|

|

|

|

|

|

#8 | |

|

destroy, rebuild, repeat

Join Date: Feb 2008

Location: Charleston, SC

Posts: 395

Rep Power: 18  |

Quote:

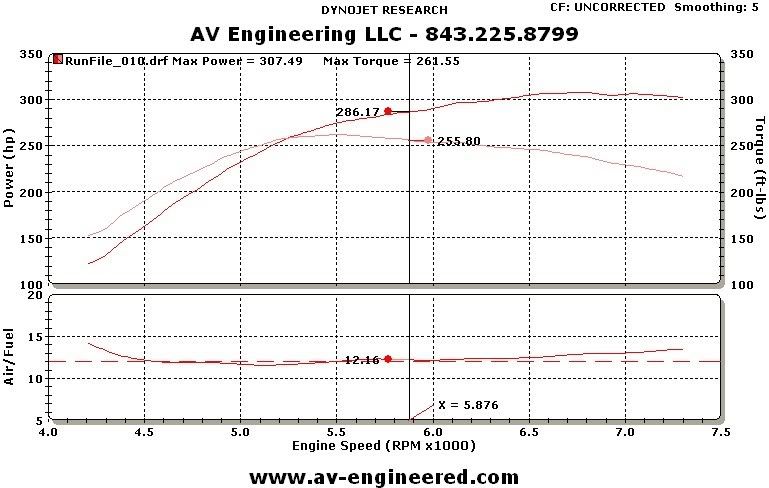

these were posted over on the other forum a while back. Here is the dyno with the front mount.. BNR stage 3, boost turned all the way up, turbo was maxed trying to fill 2.5" piping. my IC piping runs were fairly straight too  and this was with teh stock TMIC at 15psi, i did not have the ARC at this time:  same setup except for a mild streetport from rx7world. Keep in mind, this is on the dyno with little to no air moving through the IC. and the tune was a lot richer. I am now running the ARC so the numbers should be even better and it isnt cool to the touch after an autox session, its hot enough to burn you! lol But on track days on a road course it stays cool when you are actually at decent speeds. autox doesnt really work well with tmic location, not enough air flow sent2to, sorry dont mean to jack your thread, but i think this is relevant

__________________

1993 RX-7 Touring MB, stockport 13B-REW, 9.4CR rotors, T04S 60-1/p-trim single turbo 1986 RX-7 Base project track beast Last edited by 88turboii; 03-18-2010 at 07:21 AM. |

|

|

|

|

|

|

#9 | |||

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

I wasn't really talking about you, but since you asked...

Quote:

Do you ahve pics of the pipe routing? How much boost was it making - I don't know what "boost turned all the way up" means. Quote:

Quote:

-Ted |

|||

|

|

|

|

|

#10 | ||

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

Quote:

This is a local (VA/MD) shop that sells the 165 http://brwelder.com/indextemplate.cf...&SubCategory=3 Looks like they're redoing their site though. Quote:

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group |

||

|

|

|

|

|

#11 | |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Quote:

This is unfair. Cause this doesn't help me IN HAWAII. When I was down in Sac, I was surprised how discounted the welders were. Well, it shouldn't be, cause any "industrial" town would generate a lot more competition due to sales. This kinda stuff really pissed me off, cause it almost always doesn't apply to me in Hawaii. The local authorized Miller and Lincoln shops all charge close to full MSRP on their welders. Don't even ask how much tanks / gas / accessories cost... And, no, I'm not flying down there just to buy me a welder. For me, it's still going to end up costing over $2,000 for an entry-level TIG, tank, gas, cart, and consumables. I'd still like to be cool like Jesse James and use ESAB products... *sigh* -Ted |

|

|

|

|

|

|

#12 | |

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

Quote:

The best bet for simulating motion of a car is using a fan. There is no substitute besides just driving the car. And even that will be prone to error.

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group Last edited by vex; 03-18-2010 at 12:45 PM. |

|

|

|

|

|

|

#13 | ||||||

|

Pirate

Join Date: Mar 2008

Location: Central IL

Posts: 1,323

Rep Power: 19  |

Quote:

...Seriously.  In case you're bored: Quote:

Quote:

Quote:

I hear so many people bitch about how "They hate TIG welding". It provides the control of Oxy-Acetylene, but is so much more versatile. It's also one of the cleanest, and most relaxing welding processes out there. Every try doing overhead or vertical up SMAW? (Stick) Quote:

Quote:

Case in point, this would be a perfect used welder to buy from someone who's upgrading.

__________________

Rotaries:They are NOT that complicated! Last edited by Max777; 03-18-2010 at 09:19 PM. |

||||||

|

|

|

|

|

#14 | ||||

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Quote:

I'm just being honest - I wouldn't touch trying to TIG cast aluminum, period. See below for why. Quote:

I was going to blast whoever said cast iron is basically the same, but I figure I'd be nice about it... Quote:

Why bother learning it when he's the one with the welder, and he's the one that's good at it? Currently, it's a waste of my time, as I'm busy taking care of other things that are of higher priority. Quote:

It's rated at 40%, and he does work that requires it to be cooled down between welds. He's already bitching about the 40% duty cycle. I can't imagine cutting that rating in half would do to his welding work production. He's already talking about stepping up to 220A or 225A rated TIG, but that's a big step up in price. BTW, we do a lot of intercooler core installs with custom brackets. Big IC cores suck up a lot of heat, some amps and duty cycles do count. Most of our brackets are at least 1/4" thick... This is getting way off topic now... You're welcome to PM me if you want to discuss this further. ...or start a new thread. -Ted |

||||

|

|

|

|

|

#15 |

|

Test Whore - Admin

Join Date: Mar 2008

Location: Right Behind you son

Posts: 4,581

Rep Power: 10  |

Wow, I guess I have no sense whatsoever. I bought a Sync 200 a bunch of years ago, read a book, talked to a few pro's and had at it..... I'm an idiot for thinking I could learn a skill myself.

__________________

-The Angry Stig- DGRR 2009, 2011, 2012 & 2013 - Best FC DEALS GAP!! WOOHOOOO!!!!! 2015 Audi S4 - Samantha - Zero Brap S4 2004 RX8 - Jocelyn - 196rwhp, 19mpg fuel to noise converter 2000 Jeep Cherokee Sport - Wifey mobile - Now with 2.5" OME lift and 30" BFG AT KO's! So it begins 1998 Jeep Cherokee - 5 spd, 4" lift, 33" BFG's - Rotary Tow Vehicle 1988 'Vert - In progress 1988 FC Coupe - Gretchen -The attention whore BEAST! I'm a sick individual, what's wrong with you? I'm pure Evil I'm still insane, in the best possible way. I think Brian's idea of romance is using lube. Your rage caused the meteor strike in Russia. The Antichrist would be proud of his minion. You win with your thread. Most everything It's a truck with a steel gate on the back. Just a statement of fact Motec M820, AIM dash, ported 13B-RE Cosmo, 6-spd trans, 4.3 Torsen, custom twin wg fully divided mani, Custom 4" split into 2x 3" exhaust, Custom HMIC, Custom custom custom custom I like to welder stuff.... No Bolt-ons allowed. Dyno'ed @ Speed1 Tuned by me - 405rwhp on WG.... WM50 cuming soon. -Angry Motherf*cker Mode ENGAGED- |

|

|

|

|

| Bookmarks |

|

|