|

|||||||

| RX-7 2nd Gen Specific (1986-92) RX-7 1986-92 Discussion including performance modifications and technical support sections. |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| RX-7 2nd Gen Specific (1986-92) RX-7 1986-92 Discussion including performance modifications and technical support sections. |

|

|

|

Thread Tools | Display Modes |

|

|

#31 | ||||||

|

Pirate

Join Date: Mar 2008

Location: Central IL

Posts: 1,323

Rep Power: 19  |

Quote:

...Seriously.  In case you're bored: Quote:

Quote:

Quote:

I hear so many people bitch about how "They hate TIG welding". It provides the control of Oxy-Acetylene, but is so much more versatile. It's also one of the cleanest, and most relaxing welding processes out there. Every try doing overhead or vertical up SMAW? (Stick) Quote:

Quote:

Case in point, this would be a perfect used welder to buy from someone who's upgrading.

__________________

Rotaries:They are NOT that complicated! Last edited by Max777; 03-18-2010 at 09:19 PM. |

||||||

|

|

|

|

|

#32 |

|

KTEC

Join Date: Jan 2009

Posts: 642

Rep Power: 0  |

lol... this thread turned out pretty cool.

Im not going to waste my time trying to prove to some guy over the internet by paying for dyno time. I know from my own experience what works and what dosnt. and i'll leave it at that. and i dont know why your sweating over a ESAB??? lol... Lincoln or Miller are the only 2 respected welders in the business. -Keith

__________________

what I have: 1985 Gs:12a All motor Drag car - 1973 Rx2: Play car What I had: 93 Touring: TRADED - 91 Coupe: TRADED - 90 GTU: RHD - 88 10AE: SOLD - 87 Base: SOLD - 86 Base: SOLD - 1985 GSLSE - 85 Gsl: SOLD - 80 Gs: TRADED - 1972 Rx2 |

|

|

|

|

|

#33 | ||||

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Quote:

I'm just being honest - I wouldn't touch trying to TIG cast aluminum, period. See below for why. Quote:

I was going to blast whoever said cast iron is basically the same, but I figure I'd be nice about it... Quote:

Why bother learning it when he's the one with the welder, and he's the one that's good at it? Currently, it's a waste of my time, as I'm busy taking care of other things that are of higher priority. Quote:

It's rated at 40%, and he does work that requires it to be cooled down between welds. He's already bitching about the 40% duty cycle. I can't imagine cutting that rating in half would do to his welding work production. He's already talking about stepping up to 220A or 225A rated TIG, but that's a big step up in price. BTW, we do a lot of intercooler core installs with custom brackets. Big IC cores suck up a lot of heat, some amps and duty cycles do count. Most of our brackets are at least 1/4" thick... This is getting way off topic now... You're welcome to PM me if you want to discuss this further. ...or start a new thread. -Ted |

||||

|

|

|

|

|

#34 | |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Quote:

Lincoln actually has a bad rap by some experienced weldors. And if this is jab at ESAB, you have no idea what you are talking about. -Ted |

|

|

|

|

|

|

#35 |

|

Test Whore - Admin

Join Date: Mar 2008

Location: Right Behind you son

Posts: 4,581

Rep Power: 10  |

Wow, I guess I have no sense whatsoever. I bought a Sync 200 a bunch of years ago, read a book, talked to a few pro's and had at it..... I'm an idiot for thinking I could learn a skill myself.

__________________

-The Angry Stig- DGRR 2009, 2011, 2012 & 2013 - Best FC DEALS GAP!! WOOHOOOO!!!!! 2015 Audi S4 - Samantha - Zero Brap S4 2004 RX8 - Jocelyn - 196rwhp, 19mpg fuel to noise converter 2000 Jeep Cherokee Sport - Wifey mobile - Now with 2.5" OME lift and 30" BFG AT KO's! So it begins 1998 Jeep Cherokee - 5 spd, 4" lift, 33" BFG's - Rotary Tow Vehicle 1988 'Vert - In progress 1988 FC Coupe - Gretchen -The attention whore BEAST! I'm a sick individual, what's wrong with you? I'm pure Evil I'm still insane, in the best possible way. I think Brian's idea of romance is using lube. Your rage caused the meteor strike in Russia. The Antichrist would be proud of his minion. You win with your thread. Most everything It's a truck with a steel gate on the back. Just a statement of fact Motec M820, AIM dash, ported 13B-RE Cosmo, 6-spd trans, 4.3 Torsen, custom twin wg fully divided mani, Custom 4" split into 2x 3" exhaust, Custom HMIC, Custom custom custom custom I like to welder stuff.... No Bolt-ons allowed. Dyno'ed @ Speed1 Tuned by me - 405rwhp on WG.... WM50 cuming soon. -Angry Motherf*cker Mode ENGAGED- |

|

|

|

|

|

#36 |

|

RCC Addict

Join Date: Feb 2008

Location: VA

Posts: 1,812

Rep Power: 19  |

You see, this thread is why I don't fab my own stuff... I have enough heart burn as it is

|

|

|

|

|

|

#37 |

|

Rotary Fanatic

Join Date: Mar 2008

Posts: 231

Rep Power: 18  |

Geez, I make a two-sentence comment just complimenting the OP and this turns into a another 'show me the numbers' match. I would like to see some numbers as well but sometimes, it's just not a priority so too bad for the rest of us. I just thought it was neat; rarely does anybody do anything with the stock IC.

I will fabricate my own stuff if it doesn't include welding. If something needs to be welded, I know a good guy that always does our custom lab equipment. And yes, he's good with aluminium. |

|

|

|

|

|

#38 | |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Quote:

http://rx7cz.net/photos/fmic/ Haltech datalogs show it was within 3 degree F of a full GReddy FMIC kit for the FC3S. Is that what you want? -Ted Last edited by RETed; 03-19-2010 at 11:22 AM. |

|

|

|

|

|

|

#39 | |

|

KTEC

Join Date: Jan 2009

Posts: 642

Rep Power: 0  |

Quote:

except for my certification in: GTAW, FCAW, SMAW, GMAW, Oxy-acet., ect. ect. in stainless, various carbon steels, aluminum... in ALL positions and unlimited thickness. Im no garage welder. I know what im doing. And if you want to go ask 30-40 year veterans what they weld with. Or just drop by a job site and see what they are using. Red or Blue...

__________________

what I have: 1985 Gs:12a All motor Drag car - 1973 Rx2: Play car What I had: 93 Touring: TRADED - 91 Coupe: TRADED - 90 GTU: RHD - 88 10AE: SOLD - 87 Base: SOLD - 86 Base: SOLD - 1985 GSLSE - 85 Gsl: SOLD - 80 Gs: TRADED - 1972 Rx2 |

|

|

|

|

|

|

#40 |

|

Pirate

Join Date: Mar 2008

Location: Central IL

Posts: 1,323

Rep Power: 19  |

... sucess is mine. =P

__________________

Rotaries:They are NOT that complicated! |

|

|

|

|

|

#41 | |

|

Rotary Fanatic

Join Date: Mar 2008

Posts: 231

Rep Power: 18  |

That wasn't exactly what I had in mind, Ted- although that itself is also interesting. I was more or less referring to the fact that there aren't many TMIC modifications (not including the AI systems) that build upon the existing system. IMO, it always seems too easy to just slap an FMIC on and call it a day.

It's just nice to see somebody think and do outside of the box. Cheers, everyone. Quote:

|

|

|

|

|

|

|

#42 |

|

KTEC

Join Date: Jan 2009

Posts: 642

Rep Power: 0  |

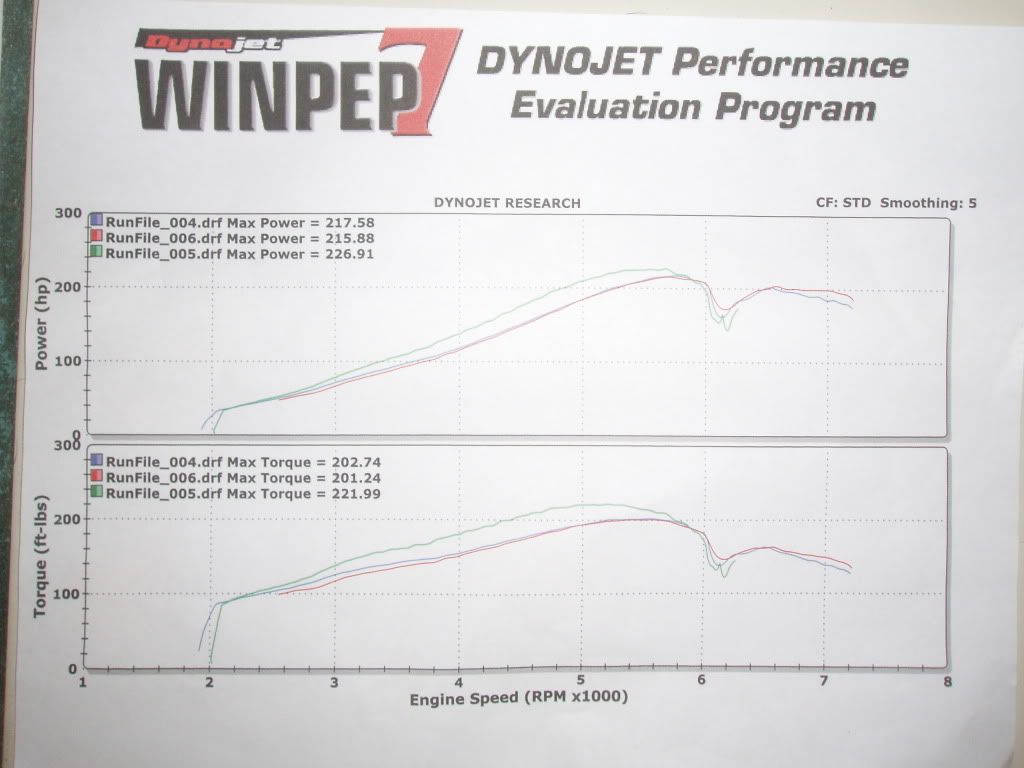

I know that this dyno proves absolutely nothing since there is no before and after. But the power band and numbers are better than i have ever seen for whats done to the car. up until the bad dip in power at around 5500rpm, wich will be resolved very soon. I will be going back to the dyno in hopes of 250whp with the problem fixed...

__________________

what I have: 1985 Gs:12a All motor Drag car - 1973 Rx2: Play car What I had: 93 Touring: TRADED - 91 Coupe: TRADED - 90 GTU: RHD - 88 10AE: SOLD - 87 Base: SOLD - 86 Base: SOLD - 1985 GSLSE - 85 Gsl: SOLD - 80 Gs: TRADED - 1972 Rx2 |

|

|

|

|

|

#43 |

|

KTEC

Join Date: Jan 2009

Posts: 642

Rep Power: 0  |

__________________

what I have: 1985 Gs:12a All motor Drag car - 1973 Rx2: Play car What I had: 93 Touring: TRADED - 91 Coupe: TRADED - 90 GTU: RHD - 88 10AE: SOLD - 87 Base: SOLD - 86 Base: SOLD - 1985 GSLSE - 85 Gsl: SOLD - 80 Gs: TRADED - 1972 Rx2 |

|

|

|

|

|

#44 |

|

Big Ugly

Join Date: Apr 2009

Location: Fredericksburg, Va

Posts: 591

Rep Power: 17  |

Hey man I commend you on upgrading the stock TMIC, the work looks clean IMO. For some reason it seems that people feel the need to make things difficult. It's funny to me how this was a thread just showing one mans effort in making something better to what brand welder is better. Honestly most of the guys I know use Lincoln a few use Miller & a couple use Hobart or ESAB. My brother who has done deep sea welding & welding at prefab concrete company prefers the Lincoln.

__________________

Boosted Big Body On 335's PS3 ID: Rotordad 1986 Mazda RX7 GXL - Street ported 13BT, Haltech, 62mm, ect. 2006 MazdaSpeed 6 - Eagle, Wiseco, Cobb, ect. |

|

|

|

|

|

#45 |

|

Pirate

Join Date: Mar 2008

Location: Central IL

Posts: 1,323

Rep Power: 19  |

So, what's the dip from? It looks like the run with the most peak power has the most significant dip, even lower than stock. What was the AFR ratio? Was this a problem of HP, or is it a fuel/timing issue? Is your ECU stock or standalone?

__________________

Rotaries:They are NOT that complicated! |

|

|

|

|

| Bookmarks |

|

|