So I've heard a bunch of a different things about this. I am looking for material or basics on radiator ducting. In particular the intake port size based on radiator size. I have heard everything from 25% area, 33% area, or 1/6 the height of the radiator. Another thing I'm curious about would it be more effective to duct directly through an intercooler to oil cooler and finally to a radiator or if it would be more effective to duct the intercooler and oil cooler and plumb fresh air through a scoop?

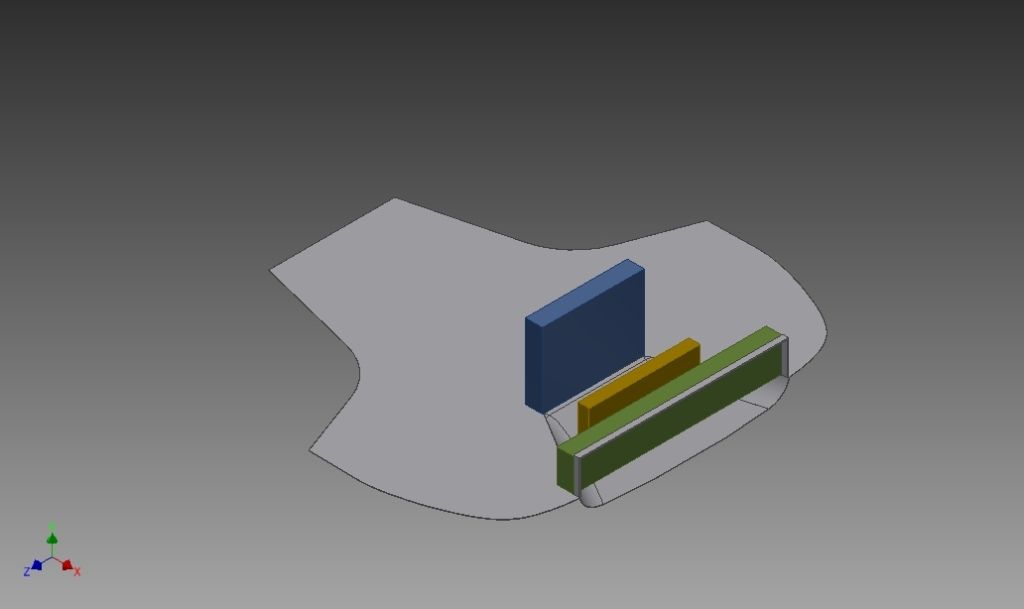

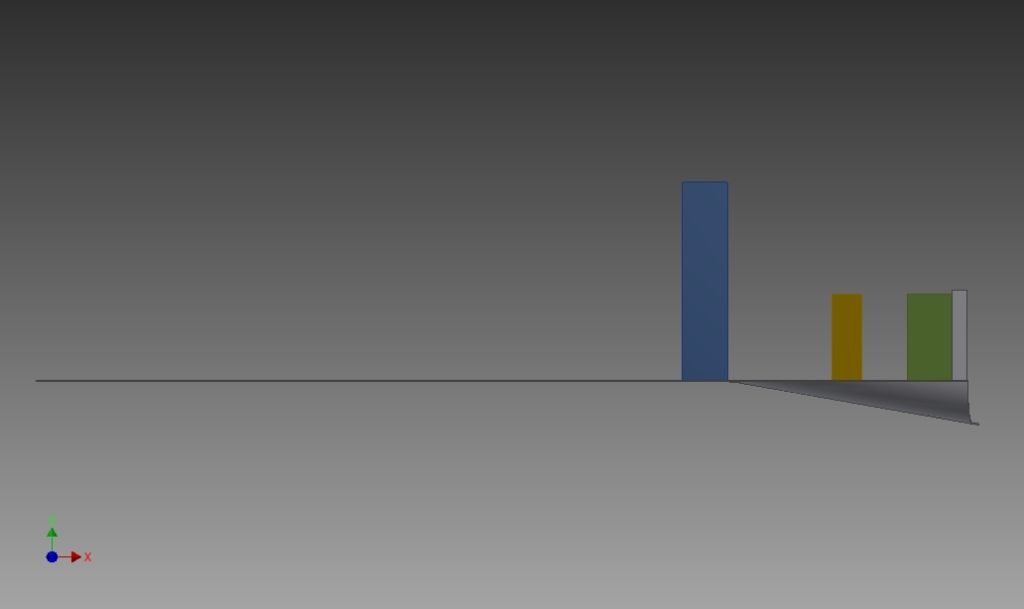

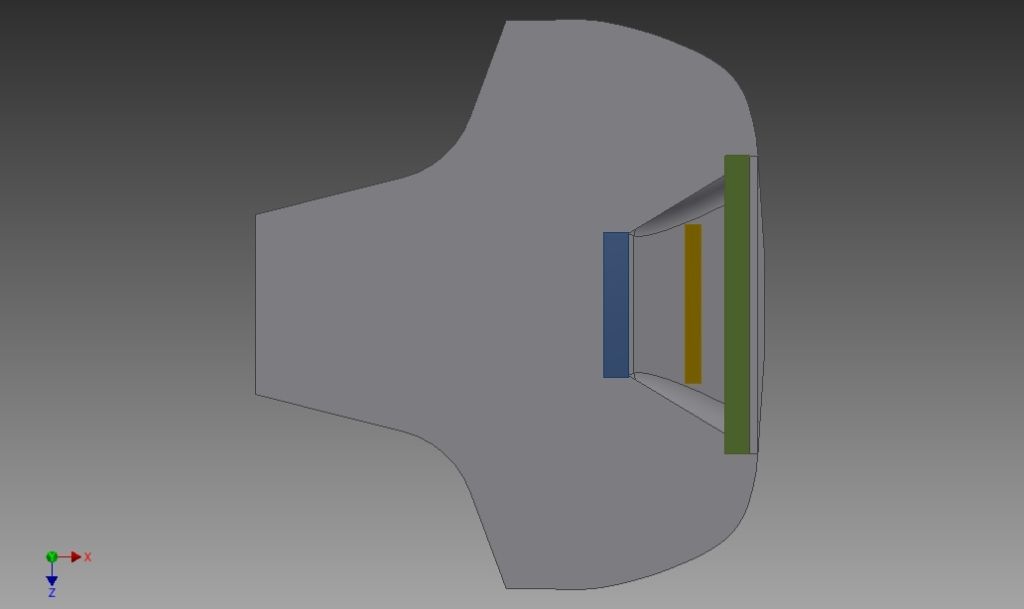

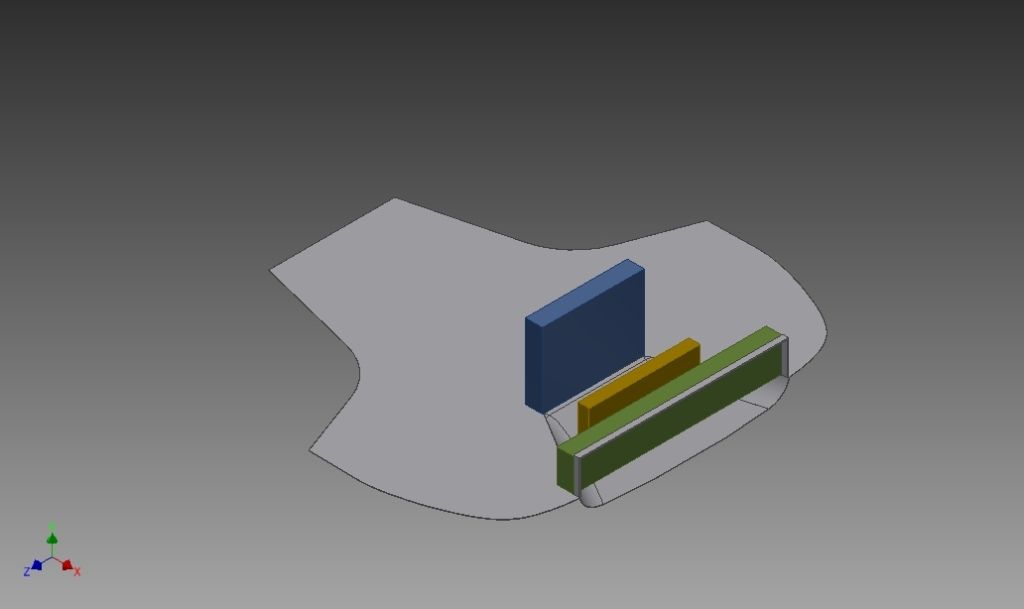

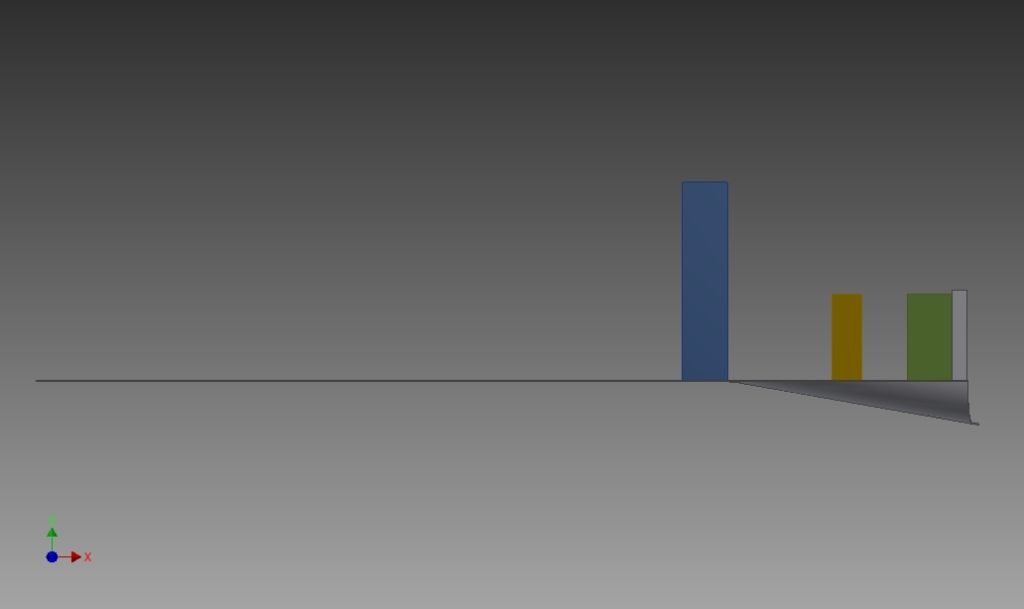

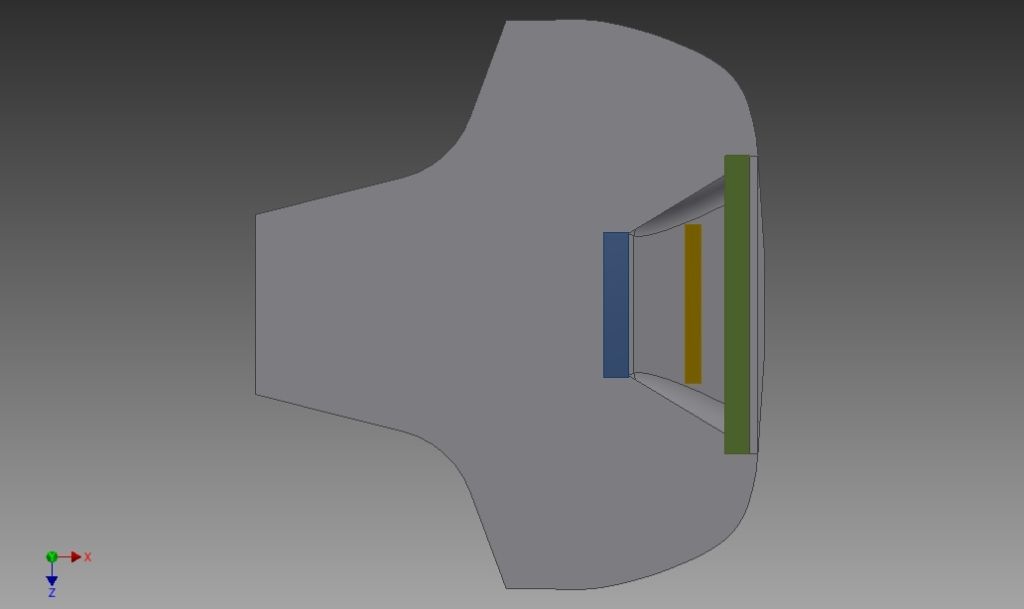

Here's a digital mock up of my particular setup and a possible version with a scoop. The plan is to duct them to be air tight between the intercooler (green) and the oil cooler (yellow) while allowing additional mass and colder air to be pulled in for the radiator. Ideally I would have liked to duct each individually and allow for fresh air to be directed on each.

Here's about the only thing I have found online recently:

http://ecomodder.com/forum/showthrea...or-6439-3.html