|

|||||||

| RX-7 3rd Gen Specific (1993-2002) RX-7 1993-2002 Discussion including performance modifications and Technical Support Sections. |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| RX-7 3rd Gen Specific (1993-2002) RX-7 1993-2002 Discussion including performance modifications and Technical Support Sections. |

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

RCC Loves Me Not You

Join Date: Mar 2008

Location: Colorado Springs, CO

Posts: 2,089

Rep Power: 20  |

Turbo manifold design

I'm looking at getting a new manifold made for a new turbo, and I was wondering what would be any benefits or drawbacks (or if it would even be possible) to mounting the turbo further back and down some, kind of like how the stock twins are, but obviously not RIGHT on the exhaust ports. I've heard long runners are better for response, but why? I would think the shortest, straightest runners possible would be better in that regard. I know putting it further back would put more heat by the ABS pump, so I'd probably put more shielding around that, and I also wonder if there would be any room for the downpipe to be mounted and angle down, but if it was lower it wouldn't have to angle as much anyway.

My main reason for asking is because I'm going to try out the new EFR 7670 and since the CHRA is longer than on a Garrett, it puts my compressor housing closer to my VMIC and then I'd have to use a smaller, more restrictive air filter and I don't want to do that. I also want to continue using an aluminum elbow off the compressor housing outlet, and in order for it to fit under the strut bar I'll have to move the turbo down a little probably. Right now I have an elbow welded onto my housing and I had them both cut a little shorter to fit under the strut bar, but I'd rather not cut down the new housing. I'm thinking of using a v-band to attach it, but then again I'd be modifying the housing, so I'm not sure on that yet either. I'd like to use an aluminum elbow either way though. If I was home with my car and could just look and take measurements, or if I had ever made a manifold, I probably wouldn't even be asking about this haha. Just curious about this though. Any thoughts? |

|

|

|

|

|

#2 |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 18  |

Opinions are like arseholes so expect many replies

I have made so many exhaust manifolds I care not to think back too much about it, I now only use on FD's the HKS T04Z manifold. This unit is "perfect" for a two rotor, the runners are ideal, the position is as well. They are very durable and you wont get anything better made by anyone. The most important bit is the power and the response, I use a turbocharger that will deliver over 750bhp @ the engine (I run it now at around ~580 to 600bhp @ 26.5psi), it clears everything with ease and this is with a "large" turbine. The before mentioned response is something I have never seen on ANY 13B street car or race car @ this high power level, I can stand on it form only 5000rpm turbine speed (not engine speed lol) (around 2500rpm) in 2nd gear and it literally launches down the road like a cannon ball being fired! it is "unbelievable" Don't place too much credit on BS dyno graphs showing you "spool to rpm" these things artificially load up the turbocharger and give it too much time to build up shaft speed and thus boost, what you are interested in is transient response all the stuff that happens from a closed throttle to your red line in under around the ~ 2 second range. A real mega set up car will accelerate so quickly in the gears (using stock Mazda gearbox with tires and final drive to do 210mph!) that you will almost find it pointless once you own one and drive it. This is what a quality manifold and turbo set up will deliver you, rather than the token 600rwhp dyno sheets some sprout out on the interwbz. A Garrett T04Z with appropriate rear housing and HKS exhaust manifold with a Tial V44 wategate and a minimum 1.3 bar spring in it and you are on the way to a sweet combination, all you need then is a decent motor, a good engine calibration, and a decent electronic boost control too. Here is a pic of how my turbo sits, I run a T04Z based turbo (modified by me) and a HKS manifold, 3.5" exhaust made by me and all heat shielded and using the factory carbon air box.  Some performance figures O.K. Remember pump petrol/gasoline here only ! ***OFFICIAL VBOX test results*** 90kmh-140kmh = 2.26 seconds! 100kmh-150kmh = 2.39 seoconds! 100kmh-200kmh = 6.25 seconds! Still on old tires, and showing about 24psi boost on the VBOX, and ~330rwkw VBOX POWER Tested at 1320kg run weight and 25 deg C ambient day, still doing boost learning procedure so there is a bit more in at this level and fuel mixture set rich to be on safe side. Fact V's Fiction Will put up some VBOX graphs when I get them off the lap dancer top Here is the graph of the 2.26 second 90-140 test  this car has a *massive* power band, not normally seen on genuine 13B road cars of this level of performance and speed!@ the word "response" does not do it justice! It builds one bar of boost at around 3400rpm in a transient test, and near its maximum boost setting well before 4600rpm and it does it even in the low gears which only take a second or two for 8000rpm, its fantastic..... best road car set up ever !@ this car has a *massive* power band, not normally seen on genuine 13B road cars of this level of performance and speed!@ the word "response" does not do it justice! It builds one bar of boost at around 3400rpm in a transient test, and near its maximum boost setting well before 4600rpm and it does it even in the low gears which only take a second or two for 8000rpm, its fantastic..... best road car set up ever !@

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration |

|

|

|

|

|

#3 |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 18  |

Making Turbine exit pipe for my SP.

And pic of my basic welding set up *hobbo set up lol*         Some more progress today, few more fittings to weld in AFR and EBP ports/fittings + finish off floating gearbox hanger support then this part is finished.     Then to fabricate SS oil drain, and water lines, couple of heat shields as well. After lunch Finished cut out of hole & welding of WG pipe        Finished AF sensor placement, also EBP sensor fitted too, all fiddly stuff really to get it to fit and be serviceable. Also have started work on decent SS304 heat shield (not finished yet), and fabricated the oil drain and inlet feed.      Totally sealed ! no radiant heat will go up to intake manifold !   Pretty happy with end result, its what I always wanted in my own car and any turbo should be like this IMHO, no more excuses of "too hot bro, cant boost it"   Well here it is, a tad over engineered!!! can be used as a third engine mount!!! (its not so bad weight is under 1kg) but its rock solid, holds coils perfectly and is very simple, each rotor coils set is modular and comes off with one cap head bolt  I probably * around for weeks on and off thinking how to do it and this way worked out best, lots of *welding and making different jigs *fiddly* especially the spacers for the coils, but that's how it goes lol   Tomorrow wire up the 3 CDI boxes and all that is done  Well here is the turbo support.

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration Last edited by RICE RACING; 12-27-2011 at 06:18 PM. |

|

|

|

|

|

#4 |

|

RCC Contributor

Join Date: Mar 2008

Posts: 535

Rep Power: 18  |

To good no words to express it , just to good

|

|

|

|

|

|

#5 |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 18  |

Thanks mate, coming from another builder of cars that is high praise

Here is some other pic's of how its shit is tucked away, bit like an Asian lady boy     V's a stock SP RX7 and how they accelerated with 276bhp motor  I have well over double the power at all rpm ranges covering 4k to 8+k...... with about 10 times the turbo reliability over the "twins" LOL (hint look at 110kmh to 140kmh 3rd gear accel time 3.72 seconds V's 1.44 seconds !!!!) same car, same weights, same stock 13B-REW engine block!, same intercooler, same air box, only difference is turbo set up, tuning...... you can turn a stock car into a supercar beater I have well over double the power at all rpm ranges covering 4k to 8+k...... with about 10 times the turbo reliability over the "twins" LOL (hint look at 110kmh to 140kmh 3rd gear accel time 3.72 seconds V's 1.44 seconds !!!!) same car, same weights, same stock 13B-REW engine block!, same intercooler, same air box, only difference is turbo set up, tuning...... you can turn a stock car into a supercar beater

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration Last edited by RICE RACING; 12-27-2011 at 07:41 PM. |

|

|

|

|

|

#6 |

|

RCC Loves Me Not You

Join Date: Mar 2008

Location: Colorado Springs, CO

Posts: 2,089

Rep Power: 20  |

LOL. Well thanks for the input, but where I'm deployed to right now, I can't see any pics on imageshack, so I can't see anything but the last pic of the magazine article LOL. I've seen your pics before though and I love your setup.

Also, I'm not selling my turbo (that I just bought) and I'm keeping the engine I have, unless it blows or something. I may have to rebuilt it already, but that's only if I determine that it's the engine burning oil and not the turbo. I can't see the HKS manifold and I haven't even seen my new turbo yet because I'm not home, so I have no idea if they would work together. I'm trying to get the manifold made with 321 stainless, and the main thing I was getting at with all this was if anyone could see a problem with moving the turbo back and down. Also, if there were any benefits or drawbacks to doing this, but I know what you're saying about opinions lol. I wondered if it might raise some sort of debate about response. I guess we'll see. Oh, I'm also planning on running two wastegates, one off each runner, probably around 38mm. The turbo supposedly flows 65lbs and the two wg should cover me I figure. I miss the responsiveness of the stock twins, so I'm going more for quick spool rather than high hp. Oh, and I'm not planning on even putting this on a dyno, so I wouldn't know the HP numbers anyway. Every time that car is on a dyno something tragic happens. I lost oil seals in a brand new turbo one time and an engine another, and possibly a brand new (rebuilt) engine again. The turbo oil seals was my fault haha. The first engine maybe my fault, the last one definitely not (if it is in fact bad). I'm also using the J-spec tranny, so my gearing so far hasn't allowed me to reach anything even close to 210 haha. Actually I don't think I've even tried to reach that haha. |

|

|

|

|

|

#7 |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 18  |

I commissioned one exhaust manifold from some place once made from 321 stainless, was made to fit HKSGT2 60mm gate and had egt's welded in etc, it was a nice piece short runner like the pics you cant see lol. (but you know what it looks like already) ....... the thing with 321 when you weld it also with 321 filler is its weld pool is "dirty" and the welds sort of come out just like when you use too much heat on 304L if you know what I mean? anyway get it made from 321 and it will last you about 20 engine and turbo oil seals

I tried the long header crap about 10 years ago. Many many people copied me,a and it in short if a con job on rotaries. it just does not work and you have way too many negatives that offset any type of gains associated with running what I call "Horse Cock Manifolds". My "opinion" is keep it short, keep it divided, keep it direct into the turbo, this will yield massive response, most energy utilization, lowest turbine inlet pressure, most power, any heat losses you have always mean you need to make up the other two of the three things that drive the compressor wheel, FLOW, PRESSURE, HEAT.... Loose any one of these and the other needs to go up to keep the energy equation balanced. Good luck with it BTW

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration |

|

|

|

|

|

#8 |

|

Rotary Fanatic

Join Date: Aug 2011

Location: crockett ca.

Posts: 176

Rep Power: 0  |

Question to rice racing:I have read that the outlet from the waste gate to the exhaust needs to be at least 18 inches long . What is your opinion on that?

|

|

|

|

|

|

#9 | |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 18  |

Quote:

I don't want to bore people with my technical shit BDC HC style but you can see the pressure build up in the exhaust as the waste gate is cycling to build up the boost to a new higher target (so the high pressure turbine inlet pressure does obviously effect the Turbine outlet pressure in those conditions) Ideal would be to vent the waste gate on its own for mega powered set up's, but I do believe that a good balance of exhaust pressure (turbine outlet pressure) to (intake manifold pressure) actually improves the engine power band. If its way lower it will give you more top end but at the expense of mid range power/response. This seems to have an effect even on stock ported rotaries. I have a nice detailed picture of the 2lt 145 inches of mercury boosted 3SGTE motor in Millen's Pikes Peak Racer and that thing at 950bhp does not have the WG 18 inches down stream (it does go right back into the exhaust outlet shortly after the turbine exit), so go figure, maybe he should have read the internet more

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration |

|

|

|

|

|

|

#10 |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 18  |

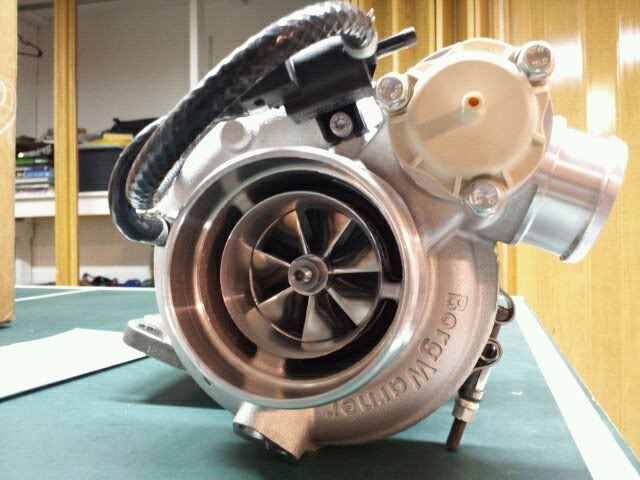

Fuck that is a nice looking turbo!

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration |

|

|

|

|

|

#11 |

|

RCC Loves Me Not You

Join Date: Mar 2008

Location: Colorado Springs, CO

Posts: 2,089

Rep Power: 20  |

Well I read that 321 holds up to heat better than other SS, that's why I wanted it. Checking out Phil's 20B thread and seeing the pics of the work Walker has done lets me know how it CAN look, if done by the right person haha. And if it's ugly, I'll just get it ceramic coated LOL. It would be nice if it's beautiful too, but I'm more concerned with it holding up over time (which I'm assuming you're saying it will with "and it will last you about 20 engine and turbo oil seals").

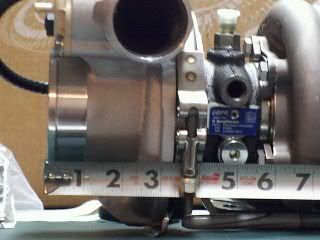

Alright, so using long runners isn't actually better then? I figured as short as possible would be better. I'd love to just make two little runners, maybe only a few inches long if possible, equal length and straight up out of the engine, but I'm not sure if the turbo will be able to squeeze down between there. I like your recommendations though...short, divided (was definitely going to get twin scroll, no question there), and try to keep it direct. Shit, I just thought of something though. If I push it lower and further back, I can say goodbye to good oil drainage. ARGH!!! Longer hoses for coolant (no big deal there) but oil drainage will be a problem. Shit. Anyway, here are some pics of my "precious"...           It's been at the house for a while, but my roommate just sent me some pics since I'm wondering what the size of this thing is. I thought the CHRA being longer would have changed a lot, but it looks not too much longer than a Garrett. |

|

|

|

|

|

#12 |

|

RCC Loves Me Not You

Join Date: Mar 2008

Location: Colorado Springs, CO

Posts: 2,089

Rep Power: 20  |

Yeah I like how it has a port for a speed sensor, but I'm not sure if I know enough about this stuff to need another gauge inside LOL. Of course, if a nearby tuner has the option to use it for tuning I'd do it, but in any case I just like that I could measure it if I need to at some point. I'd love to learn how to do my own tuning, but I don't know if that day will ever come haha. When I was doing research on this turbo I was reading about turbo speed and how it's used to tune, it's pretty interesting. I don't remember at all what it said right now, but I remember where to find it and I remember that I thought it was interesting at the time HAHA.

|

|

|

|

|

|

#13 |

|

Turblown Engineering

Join Date: Feb 2008

Location: AZ

Posts: 62

Rep Power: 18  |

If you can fit a shorty manifold that will flow nice it is definitely the best way to go. When I say flow nice I mean the bends have to be as gentle as possible, and absolutely no cheating of the entrance to the turbo manifold. In all honestly it doesn't make that much difference from long vs short, engine build quality will way out weigh it.

Check out this SWEET Rx-8 turbo manifold we pulled off a customer's car..  Curious to see how your EFR works out, I've got tons of guys asking me about doing those.. |

|

|

|

|

|

#14 |

|

RCC Loves Me Not You

Join Date: Mar 2008

Location: Colorado Springs, CO

Posts: 2,089

Rep Power: 20  |

Yeah I'm really hoping to do as short and straight as possible, or at least gentle bends actually. What do you mean no cheating on the entrance? I know I'm just being finicky here, but anything that will help with faster spool is what I'm after.

That's an interesting manifold, I've never seen one done like that before. I don't remember, does the RX-8 exhaust come out of the irons too instead of the housings? Is that why there are 3 ports on there? Yeah I'm curious too haha. Unfortunately I won't be able to provide any dyno results since I don't dare get on another one HAHA. All I'll be able to do is give a report on what the butt dyno tells me, how fast it spools and all that. Also, I'll be at a disadvantage due to the 6000' altitude as well, but I do plan on taking this to DGRR this year (assuming I can get it all done in time), so that should give me a better idea of what it will do near sea level. Otherwise I guess I'll run the current turbo out there. Either way, I'm sure I'll be reporting whether I'm happy or not haha. MAYBE I'll get on the dyno just to do a couple pulls, but no tuning, that's when tragedy strikes. I've been fairly lucky enough with just dyno pulls though. |

|

|

|

|

|

#15 | |

|

Test Whore - Admin

Join Date: Mar 2008

Location: Right Behind you son

Posts: 4,581

Rep Power: 10  |

Quote:

As Peter pointed out, take a look at the Twins Turbo manifold. Beautifully constructed, out side the box thinking, not all that impressive numbers. As for your tuning experiences.... get a better dyno guy! What's breaking and what boost, timing, AFR's etc etc etc...

__________________

-The Angry Stig- DGRR 2009, 2011, 2012 & 2013 - Best FC DEALS GAP!! WOOHOOOO!!!!! 2015 Audi S4 - Samantha - Zero Brap S4 2004 RX8 - Jocelyn - 196rwhp, 19mpg fuel to noise converter 2000 Jeep Cherokee Sport - Wifey mobile - Now with 2.5" OME lift and 30" BFG AT KO's! So it begins 1998 Jeep Cherokee - 5 spd, 4" lift, 33" BFG's - Rotary Tow Vehicle 1988 'Vert - In progress 1988 FC Coupe - Gretchen -The attention whore BEAST! I'm a sick individual, what's wrong with you? I'm pure Evil I'm still insane, in the best possible way. I think Brian's idea of romance is using lube. Your rage caused the meteor strike in Russia. The Antichrist would be proud of his minion. You win with your thread. Most everything It's a truck with a steel gate on the back. Just a statement of fact Motec M820, AIM dash, ported 13B-RE Cosmo, 6-spd trans, 4.3 Torsen, custom twin wg fully divided mani, Custom 4" split into 2x 3" exhaust, Custom HMIC, Custom custom custom custom I like to welder stuff.... No Bolt-ons allowed. Dyno'ed @ Speed1 Tuned by me - 405rwhp on WG.... WM50 cuming soon. -Angry Motherf*cker Mode ENGAGED- |

|

|

|

|

|

| Bookmarks |

|

|