|

|||||||

| Rotary Tech - General Rotary Engine related tech section.. Tech section for general Rotary Engine... This includes, building 12As, 13Bs, 20Bs, Renesis, etc... |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| Rotary Tech - General Rotary Engine related tech section.. Tech section for general Rotary Engine... This includes, building 12As, 13Bs, 20Bs, Renesis, etc... |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

The Newbie

Join Date: Mar 2008

Posts: 13

Rep Power: 0  |

Dyno?

Hi all.

I have recently had the Fd set up and when i received the Print out i noticed the Torque Curve sort of Drops off between 4500 and 5500 then Picks up again as the revs increase.  I am not too clued up on Dyno print outs but from what i have seen this looks like i have an issue or a Fault as it still does it on lower boost (its not very clear but big red line is 1 bar and just under it is a Yellow line which is 0.8 bar the lower lines where on a Different IC that was holding it back but the dip is still there) A Basic Mod list: PFC with Profec B2 Boost controller Mild Ported Motor with 3mm seals Hybrid 60-1 turbo (.96 hot side), HKS Divided manifold, 50mm WG 3" exhaust (decat) Stock Primary Injectors and 1600cc secondary’s, Aeromoive FPR, 044 Pump WI Injection ( 50/50 .6mm jet by the Throttles) HKS Twin Power (10's and 11's Plugs) Blitz FMIC I was told by the Dyno operator that the dip was due to poor gas flow through the Manifold, but i have read that if the manifold had reached its peak flow the Torque wouldn't climb anymore? Can anyone enlighten me as this is an Area i really know little about? Thanks

Last edited by Grizzly; 10-11-2012 at 11:07 AM. |

|

|

|

|

|

#2 |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Who did the P-FC tuning?

It looks like a tuning issue... -Ted |

|

|

|

|

|

#3 |

|

The Newbie

Join Date: Mar 2008

Posts: 13

Rep Power: 0  |

Last edited by Grizzly; 10-11-2012 at 11:02 AM. |

|

|

|

|

|

#4 |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

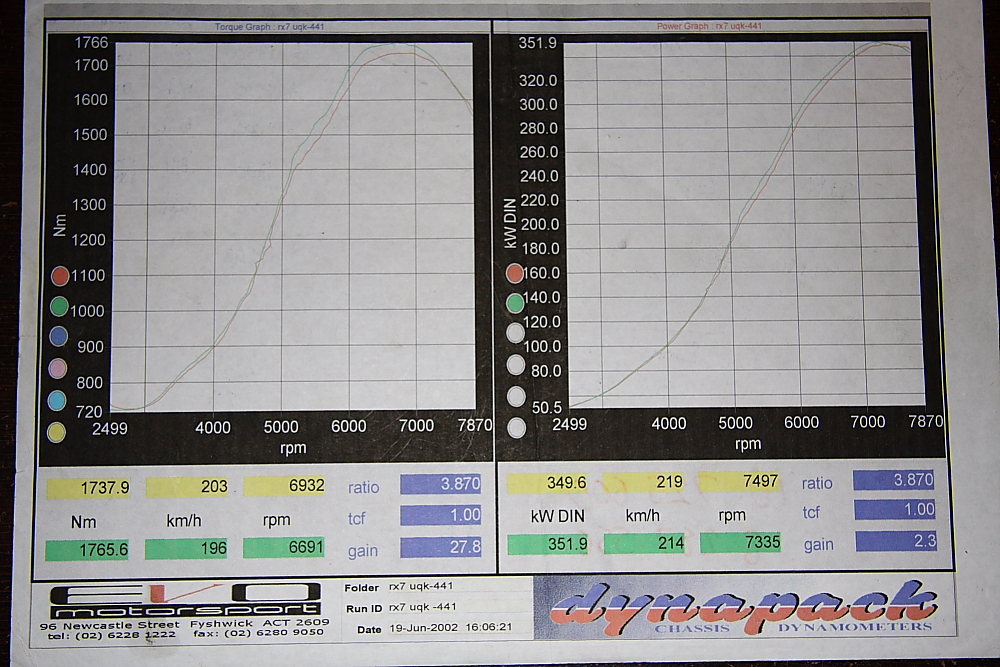

Don't know too much about the scene in the UK, so I can't comment on "rotary specialist"...

I do have experience with the DynaPack dyno... My personal car that I did some quick tuning after swapping turbos - the old turbo died. 1987 FC turbo, 13BT, compressor upgrade T04E "60 trim", 10psi Not as much power as yours, but you see the general trend of the graph...  Thick red was baseline run Thick green was after tuning the Haltech E8 to get rid of that dip from 4.5k+. That dip sorta kinda looks like yours... So I know you can tune it better to get rid of it.  The above dyno was only about 30 minutes of tuning. It picked up 10 - 15 lb-ft of torque from 5k+. I maybe did 3 runs total after baseline. I was surprised it managed to hit 240 on the DynaPack. Adjusted for DynoJet #'s, conservatively, it's in the 260's range. The car was still running *stock* fuel pump, so there was no reason to go any further. -Ted |

|

|

|

|

|

#5 |

|

The Newbie

Join Date: Mar 2008

Posts: 13

Rep Power: 0  |

I just watched the Video a cupple of times and at around 4500 the afr drops from upper 10's to aprox 10.2 afr is that what should be tuned out so it stays solid at for example 10.7 whilst your hitting peak boost? or wouldn't that make much of a diffrence?

|

|

|

|

|

|

#6 |

|

The Newbie

Join Date: Mar 2008

Posts: 13

Rep Power: 0  |

Class, just Noticed i've put this in the wrong section. Sorry.

What can you say these Noobs coming on your Forum messing it up

|

|

|

|

|

|

#7 |

|

Test Whore - Admin

Join Date: Mar 2008

Location: Right Behind you son

Posts: 4,581

Rep Power: 10  |

Nothing, we enjoy new people on this forum as long as they don't kick the bee hive with the intention of seeing the freenzy

The AFR's dropping like that would account for the loss of power. How much boost are you running? 10.7:1 is way WAY toooooo rich unless it's some insane amount of boost and meth injection. Personally, on pump, I run 12.5:1 up to 10psi... but that's me and my car. I don't tune cars that way.

__________________

-The Angry Stig- DGRR 2009, 2011, 2012 & 2013 - Best FC DEALS GAP!! WOOHOOOO!!!!! 2015 Audi S4 - Samantha - Zero Brap S4 2004 RX8 - Jocelyn - 196rwhp, 19mpg fuel to noise converter 2000 Jeep Cherokee Sport - Wifey mobile - Now with 2.5" OME lift and 30" BFG AT KO's! So it begins 1998 Jeep Cherokee - 5 spd, 4" lift, 33" BFG's - Rotary Tow Vehicle 1988 'Vert - In progress 1988 FC Coupe - Gretchen -The attention whore BEAST! I'm a sick individual, what's wrong with you? I'm pure Evil I'm still insane, in the best possible way. I think Brian's idea of romance is using lube. Your rage caused the meteor strike in Russia. The Antichrist would be proud of his minion. You win with your thread. Most everything It's a truck with a steel gate on the back. Just a statement of fact Motec M820, AIM dash, ported 13B-RE Cosmo, 6-spd trans, 4.3 Torsen, custom twin wg fully divided mani, Custom 4" split into 2x 3" exhaust, Custom HMIC, Custom custom custom custom I like to welder stuff.... No Bolt-ons allowed. Dyno'ed @ Speed1 Tuned by me - 405rwhp on WG.... WM50 cuming soon. -Angry Motherf*cker Mode ENGAGED- |

|

|

|

|

|

#8 |

|

The Newbie

Join Date: Mar 2008

Posts: 13

Rep Power: 0  |

The car was set up to 1.1bar of Boost and it does run 50/50 Meth Water mix but through a 0.6mm Jet by the Throttles and comes on at 0.7 bar, the only thing i can say is the Meth/Water mix is sending it rich maybe? Could it have been set like this to keep it on the rich side so airing on the side of Caution?

|

|

|

|

|

|

#9 | |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Quote:

Either or would cause that dip. Going with the AFR's you mentioned, it sure sounds like too much fuel... I wouldn't get critical of the AFR's (and also total ignition advance) until you start to get close to maximum torque. Looking at your graph, it looks to be right under 6k RPM (if that dip wasn't there). Running in the 10's that far away from peak torque is just way too much fuel, especially when it's on the lower RPM side of the peak. With the car on the dyno, that's all you really need in terms of "tools." (I can argue EGT gauge at this point, but most of you are already tired of that.  ) )Just adjust fuel as long as power keeps going up - simple. People get too caught up with AFR's, etc. to understand the dynamics of tuning. -Ted |

|

|

|

|

|

|

#10 | ||

|

Test Whore - Admin

Join Date: Mar 2008

Location: Right Behind you son

Posts: 4,581

Rep Power: 10  |

Quote:

Quote:

That.....

__________________

-The Angry Stig- DGRR 2009, 2011, 2012 & 2013 - Best FC DEALS GAP!! WOOHOOOO!!!!! 2015 Audi S4 - Samantha - Zero Brap S4 2004 RX8 - Jocelyn - 196rwhp, 19mpg fuel to noise converter 2000 Jeep Cherokee Sport - Wifey mobile - Now with 2.5" OME lift and 30" BFG AT KO's! So it begins 1998 Jeep Cherokee - 5 spd, 4" lift, 33" BFG's - Rotary Tow Vehicle 1988 'Vert - In progress 1988 FC Coupe - Gretchen -The attention whore BEAST! I'm a sick individual, what's wrong with you? I'm pure Evil I'm still insane, in the best possible way. I think Brian's idea of romance is using lube. Your rage caused the meteor strike in Russia. The Antichrist would be proud of his minion. You win with your thread. Most everything It's a truck with a steel gate on the back. Just a statement of fact Motec M820, AIM dash, ported 13B-RE Cosmo, 6-spd trans, 4.3 Torsen, custom twin wg fully divided mani, Custom 4" split into 2x 3" exhaust, Custom HMIC, Custom custom custom custom I like to welder stuff.... No Bolt-ons allowed. Dyno'ed @ Speed1 Tuned by me - 405rwhp on WG.... WM50 cuming soon. -Angry Motherf*cker Mode ENGAGED- |

||

|

|

|

|

|

#11 | |

|

The Newbie

Join Date: Mar 2008

Posts: 13

Rep Power: 0  |

Quote:

but now a bit on i'm thinking i've lost out of some extra Water Cooling effect and caused a tuning issue (its set up rich and if its tweaked back to 11's for argument sake and the Pump stops and then would that send me very lean on Boost) but now a bit on i'm thinking i've lost out of some extra Water Cooling effect and caused a tuning issue (its set up rich and if its tweaked back to 11's for argument sake and the Pump stops and then would that send me very lean on Boost) I have one more question, are datalogits and Wideband kits a good thing to have or is it a case of Not clever in the wrong hands. TBh i proberly wouldn't like to touch the map myself buy i don't like the idea its been set up by some one who hasn't tuned out some thing that Ovious and i'd like to see what the rest of the maps doing. |

|

|

|

|

|

|

#12 | |

|

The Newbie

Join Date: Mar 2008

Posts: 13

Rep Power: 0  |

Quote:

|

|

|

|

|

|

|

#13 | ||

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Quote:

We can run that kinda boost, but I'll drop the total ignition advance a little just to keep it on the safe side. I'll take the several percentage points drop in power just to keep the engine safe on the street with the deviation in gasoline (octane) quality. RICE RACING is da man to talk to when talking about that supplemental injection stuff. In fact, there's a good thread in another section somewhere where there's a lot of good numbers for this kinda stuff. I personally don't touch this stuff, so I'm not qualified to answer such questions. Just looking at your graph though... You're losing around 20 lb-ft (or more) in that "dip" section. That's a pretty significant amount of power, especially in the middle of your power band. It would be nice to fix it and gain back that lost power.  Quote:

It looks like it unlocks a bunch of auxiliary maps and allows (more) datalogging. Datalogging can be of great help for tuners, or if you do a lot of adjustments (driving by) yourself. It still comes down to the capabilities of the tuner... You can give the best tools to a crappy tuner, but it still won't help if they don't know how to utilize those tools. A good tuner can get by with barebones monitoring (i.e. gauges) and tools, and still be more effective than the crappy tuner. -Ted |

||

|

|

|

|

|

#14 | |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 19  |

Quote:

You do not need such a system at all (not even up to 1.3 bar boost pressure on T4 frame turbo's) as correct fuel richness levels and spark advance will suffice any effects towards detonation. To run water injection without the associated dips you need to have the engine fully mapped for one or the other, you can not run your engine optimized for one and then expect it to run in another way with water injection you will always have non optimal result. For a PFC or any other basic system you make the choice which way you want to go. If you run a Life Racing, Syvec, or Motec ECU etc then you can have multiple strategies and different maps that all are tuned to allow different configurations for fueling and ignition mapping, and switch it as you see fit. All of this is explained in great detail in my thread in members section or on the Aquamist site (only free source worth reading on the topic of water injection).

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration |

|

|

|

|

|

|

#15 |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 19  |

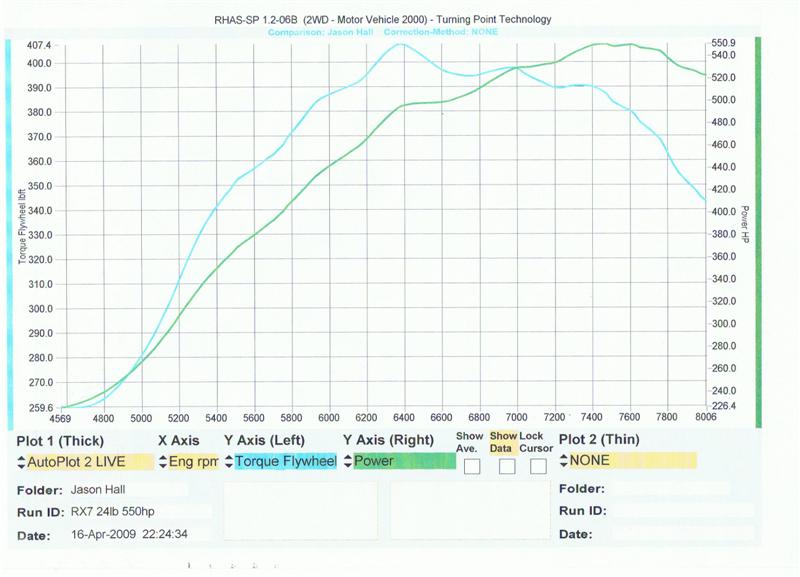

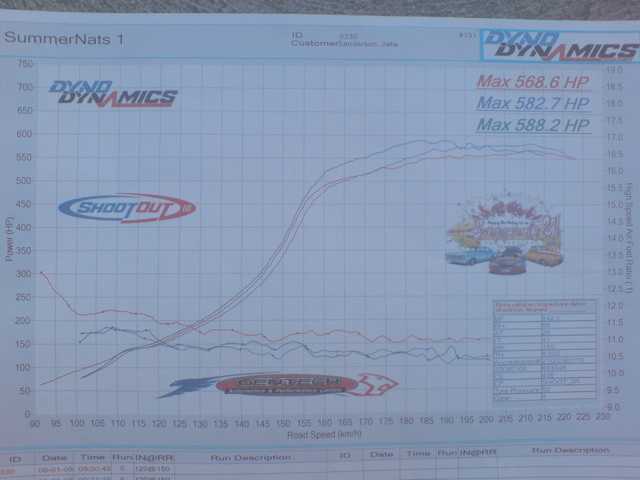

http://www.riceracing.com.au/water-injection.htm

^ The only real legitimate source for rotary turbo water injection knowledge, that is proven and achieved by others and not touch typed on your local trashy forum by some nobody pony tailed or plastic trophy time attack racer lol .................. Dyno's of engines properly set up to run water injection (all forms). No dips   472rearhubhp 1.3 bar Water Injected  550rearhubhp 1.7 bar Water Injected  558rearwheelhp ~1.7bar Water Injected Some examples for you

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration |

|

|

|

|

| Bookmarks |

|

|