|

|

#16 |

|

Where are the girls?

Join Date: Jan 2012

Location: Wilmington, NC

Posts: 27

Rep Power: 0  |

I see that you said that you are relocating your wastegates...any idea of what you are going to do to them? Just extend the runners rearward?

__________________

BMW 330i daily 1993 FD3S |

|

|

|

|

|

#17 | |

|

Rotary Fanatic

Join Date: Feb 2008

Location: Gresham, OR

Posts: 473

Rep Power: 18  |

Quote:

__________________

|

|

|

|

|

|

|

#18 |

|

The Newbie

Join Date: Apr 2009

Posts: 17

Rep Power: 0  |

Pics of the final hood vent. No issues with the big boys at Nationals this year that we know of.

|

|

|

|

|

|

#19 | |

|

RCC Loves Me Not You

Join Date: Mar 2008

Location: Colorado Springs, CO

Posts: 2,089

Rep Power: 20  |

Quote:

So glad to hear you don't have any issues with oil drainage. I'm kinda worried about the waste gate being heat soaked though, but I guess water cooling will help that. Have you thought about where you're going to get the water from and route it back to? Where are you thinking of relocating it to? Have you thought about making a heat shield for that WG? Is there any concern welding the 321 to the 304? Mainly about cracking where the 321 meets the 304 flange? About the 4" though, is it not started at the back of the turbo? Or are you saying you started using 409 at the rear of the tranny and prior to that it's 321? That must have been pricy for all that 321 lol. So THAT'S why you plumbed them back into the exhaust. I wonder if there is some kind of quick disconnect for that piping to make it easier to connect. Yeah I can understand using a cheap core for an experiment. Do you notice any drawbacks to that ebay core? I guess it's working for you if you're racing with it lol. I'm still wary of what size core to get, I'd rather experiment with a cheap core too but if it works I don't want to build another one with a name brand core. Although maybe it would still be worth it to try. So as far as response, what would you say about how much difference there is between this and stock twins? That fuel setup is crazy haha. I'd love to do something like that, I'm just not sure what all to do. Thanks for the help! |

|

|

|

|

|

|

#20 | |

|

Rotary Fan in Training

Join Date: Apr 2009

Posts: 49

Rep Power: 0  |

Quote:

__________________

CT 93' FD |

|

|

|

|

|

|

#21 |

|

Where are the girls?

Join Date: Jan 2012

Location: Wilmington, NC

Posts: 27

Rep Power: 0  |

guess my posts dont show up or something guess my posts dont show up or something

__________________

BMW 330i daily 1993 FD3S |

|

|

|

|

|

#22 | |

|

Rotary Fan in Training

Join Date: Apr 2009

Posts: 49

Rep Power: 0  |

Quote:

First I am going to water cool them and see if that helps. I currently have the rear wastegate wrapped with heat shielding but it still melts the diaphragm. My plan is to pull the engine soon for a swap and investigate what I can do to help the issue. I really do not have a good fix at this time nor do I want to re make the manifold or DP.

__________________

CT 93' FD |

|

|

|

|

|

|

#23 | |

|

Rotary Fan in Training

Join Date: Apr 2009

Posts: 49

Rep Power: 0  |

Quote:

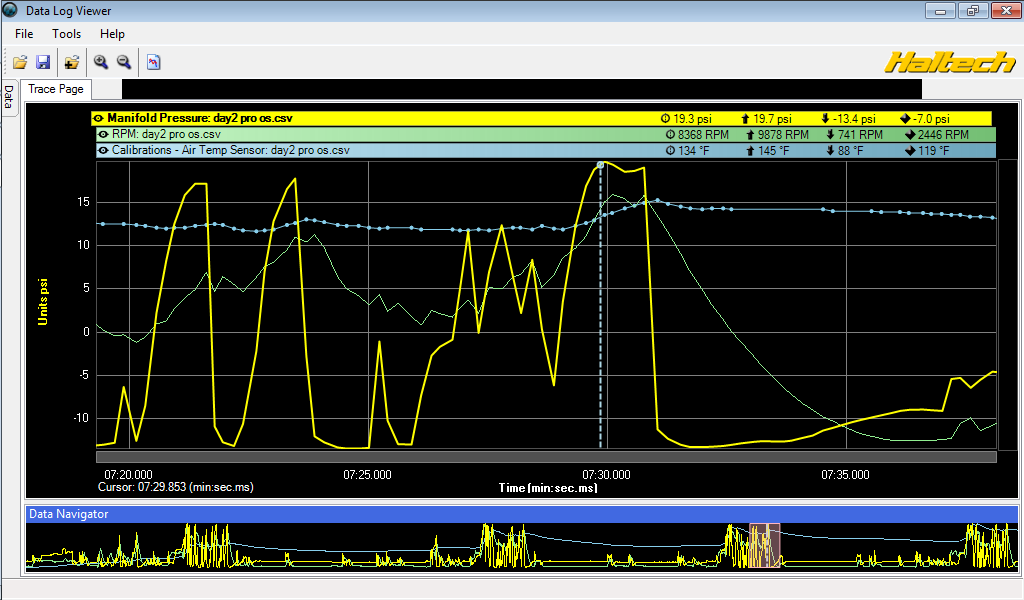

1. Manifold 321ss 2. 3" vband 304ss 4. 3" to 3.5 transition 321ss 5. DP 3'5" 321ss 6. flex joint 304 ss 7. 3.5 to 4" transition 321ss 8. 4" straight section 26"s, 321ss (removable to be straight or Magna flow) 9. 4" from #8 back to Magna flow in rear 409ss My plan was to run 20 ga. 321 all the way back but it was hard to justify the cost to material advantage. On the IC, my intake temps get a little high. 145F-175F range during a race on a 90+ degree days. Not sure if it is the IC or the nature of the beast. I usually run 19-21psi so the intake temps get up there. The example I pulled up happened to be a little cooler day might have been 80 degrees at the most. not really sure. The stock twins are no comparison to the single I have on it now. Best way I can explain it is it would be the difference in a C6 Z06 compared to a stock RX-8.

__________________

CT 93' FD Last edited by cturbo28; 01-17-2012 at 09:15 PM. |

|

|

|

|

|

|

#24 | |

|

Where are the girls?

Join Date: Jan 2012

Location: Wilmington, NC

Posts: 27

Rep Power: 0  |

Quote:

__________________

BMW 330i daily 1993 FD3S |

|

|

|

|

|

|

#25 | ||

|

RCC Loves Me Not You

Join Date: Mar 2008

Location: Colorado Springs, CO

Posts: 2,089

Rep Power: 20  |

Quote:

I'm not sure how you kept all those materials and locations straight in your mind haha, but thanks for the info! I thought you went straight from the Vband on the turbo to a 4" DP. Gotcha. And I can completely understand not doing the whole thing in 321ss, not worth the benefit vs cost. Was there a specific reason you got an RB flange? Someone else suggested getting that one too but I don't yet know why. I'll get it anyway though, no biggie. As far as the cooling efficiency of the IC, I've never measured my temps so I wouldn't know how they compare to yours, but I know current VMIC works pretty well as far as cooling. I just think I might be able to get less pressure drop with something with smoother flowing end tanks. Then comes the problem of the air moving too fast to be cooled efficiently...and for that I was going to use 2.75" exit and 3" entrance piping. But flow/CFM is where I'm stuck right now. Not that it really matters, I'm not racing, just trying to give my all to build my favorite street car haha. MAYBE it'll see the track someday, but I've never paid attention to rules and regulations so I'm so far past it now and it's not worth going back. So you're saying the single responds faster than the stock twins? Or are you talking just about the power it delivers? I didn't think any single would respond as fast as the twins. I was hoping short runners and an efficient IC would help though. Sorry for all the questions, but thanks for responding anyway. Quote:

|

||

|

|

|

|

|

#26 | ||

|

Rotary Fan in Training

Join Date: Apr 2009

Posts: 49

Rep Power: 0  |

Quote:

Quote:

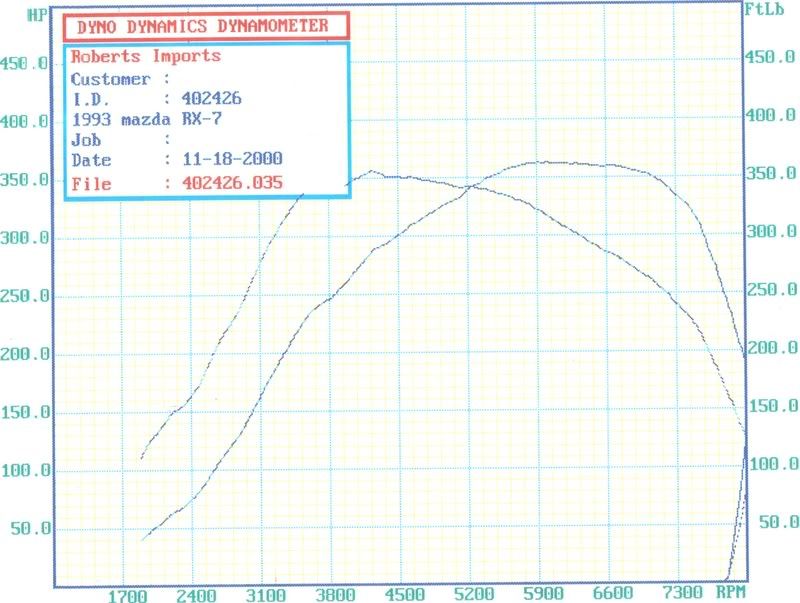

I will post my dyno chart and let you figure out if the twins are better. Although for a street car I would get a bigger turbo like a GT35 or so. The street is another world compared to auto crossing.

__________________

CT 93' FD Last edited by cturbo28; 01-18-2012 at 09:13 PM. |

||

|

|

|

|

|

#27 |

|

RCC Loves Me Not You

Join Date: Mar 2008

Location: Colorado Springs, CO

Posts: 2,089

Rep Power: 20  |

I was on the computer at work when I responded last so I didn't even see the graph you posted then lol. I'm eager to see how you remedy the WG issue, and the routing of the cooling lines as well.

I hear ya. I've thought about that myself, especially since I probably won't even plan to race it anymore haha. I have a 500R-SP currently, and I'm putting in a BW EFR 7670 when I get home. That's what this manifold will be for. Thanks! |

|

|

|

|

|

#28 | |

|

Sua Sponte

Join Date: Feb 2008

Location: Killeen, TX

Posts: 839

Rep Power: 18  |

Quote:

__________________

Road Atlanta August 2011 NASA TT 1:33 http://www.youtube.com/watch?v=IFY00PAK_Ps Traqmate's video of my car from the 2011 UTCC at VIR http://www.youtube.com/watch?v=2Zcn6...layer_embedded Video of Yellow LS1 FD at NASA TT at VIR http://www.youtube.com/watch?v=e6k0lJkcwrM |

|

|

|

|

|

|

#29 |

|

RCC Loves Me Not You

Join Date: Mar 2008

Location: Colorado Springs, CO

Posts: 2,089

Rep Power: 20  |

^I agree, but I also don't want to end up going with a different design and end up with worse results, know what I mean? I'm trying to move forward here, not backwards LOL.

|

|

|

|

|

|

#30 |

|

Rotary Fan in Training

Join Date: Apr 2009

Posts: 49

Rep Power: 0  |

Build update

I have started my engine swap on the FD. I will be doing this in stages so I can make the races I plan to attend. I am trying not to get too many projects going at once.

Stage 1: Engine swap, built by David Jerome. Excessive LIM ( Thanks Jeff Kiesel) Newer transmission from 36K donor car (Thanks tomsn16) Swap diffs (I was planning on testing out some things for the first race) Addition of EGT probes so I can log the exhaust temp. (Thanks Ludwig) Addition of back pressure sensor to log pressure in manifold. (Thanks Ludwig) Fix damaged fender ( Thanks to my body shop dude and Brent for the donation!) Dyno tune ( Ludwig) Stage 2: Electric water pump controlled via Ludwig installed Haltech Electric power steering pump from S2000 Relocate Alternator. ( not yet decided) Maybe play with different exhaust housing based on the data from stage 1 results. Also here are some pictures of the damage I did last Sunday.

__________________

CT 93' FD Last edited by cturbo28; 02-04-2012 at 09:41 AM. |

|

|

|

|

| Bookmarks |

|

|