|

|

#46 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

Haven't really yet driven this car to get a feel for its power & torque, I don't really expect much since its a mild ported S4 NA.

I did get the oil leak fixed, kind of, its still leaking a little where the other plug is in the oil filter pedestal. Probably just needs some sealant. Updated Engine picture.  And how its going to look for now until the next cosmetic change.  I made a hood scoop block off plate. Its a little rough. I'm not using the scoop anyway, and this should keep most of the rain out. |

|

|

|

|

|

#47 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

Engine specs.

As of now. Nothing really special. Its basically an S4 NA. 9.4 comp rotors, S4 intake manifolds. Apex seals are RA Classics. Also has FD corner seal springs. Porting: End plates have been street ported. Mild? Housings have had the NA diffusers grinded out. And ports have been mildly ported. Exhaust has RB mufflers and pre-silencer. Clutch is a Clutch Masters stage 2. Air filter is an Advanced Auto Parts store bought cone style. Radiator is a no-name brand from an online discount parts store. Lawn mower battery from walmart. It still has all the original S5 electronics. It has had the following components removed for various reasons. Emissions equip. Rats nest, air pump, etc. All the AC components. Power steering pump. And bracket. 2ndary throttle plates. Aux port sleeves and actuating rods. And a bunch of other misc. parts from the engine bay. Like sub-zero start tank, washer fluid tank, etc, etc. |

|

|

|

|

|

#48 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

So the 7 has been down for upgrades since 10 days ago, I'm not going to post about it yet as not to jinx it.

But I will show a little something on the side from the main project. This:    I decided to try out Fiberglass work for the first time, and repair an old under-tray. The works a little messy, but I can handle it. And I know it looks like crap. I followed the directions from the can, and used about 4 squares of fiberglass. That's it for now.

__________________

'89 RX7 GTU, half-Bridge-port S4/S5 NA, E6K, Full RB exhaust, weekend warrior. '83 RX7, The "this might take awhile" project. '87 RX7 GXL, Rest In Pieces. '98 Subaru Impreza Outback-sport, rx7 rescue vehicle, down for repair. '94 Ford Ranger, daily. |

|

|

|

|

|

#49 |

|

www.aerokits.net

Join Date: Mar 2010

Posts: 33

Rep Power: 0  |

If it works, it works.

__________________

Chaser Aerodynamics, LLC Please visit our website!! Use coupon code: JB1013 to save 10% on your web order! (866) 360-KITS (5487) ext: 107 |

|

|

|

|

|

#50 |

|

My minds tellin' me no...

Join Date: Feb 2008

Location: Murfreesboro, TN

Posts: 4,043

Rep Power: 22  |

Not like anyone sees it.

I say good job.

__________________

1976 Mazda Cosmo RX-5 1976 Mazda Cosmo RX-5 2003 Toyota Tundra TRD 2015 Toyota 4Runner SR5 |

|

|

|

|

|

#51 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

Well after a month of working on it, I got it started last night, and took it for a drive at noon today.

I still have a few bugs to work out, like an exhaust leak an such. That's it for now.

__________________

'89 RX7 GTU, half-Bridge-port S4/S5 NA, E6K, Full RB exhaust, weekend warrior. '83 RX7, The "this might take awhile" project. '87 RX7 GXL, Rest In Pieces. '98 Subaru Impreza Outback-sport, rx7 rescue vehicle, down for repair. '94 Ford Ranger, daily. |

|

|

|

|

|

#52 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

Alrighty, I'm so excited about this.

Here's what I've done, Last year sometime I acquired a Turbo setup for cheap. Turbo, manifold, downpipe, intercooler, and some elbows, included. I finally got to doing the project a month ago. Finished it a few days ago. Pictures and details coming very soon. I am taking it to DGRR and the Mitty. I think from where I'm coming from, when I get back home, Ill have around 1000 extra miles on it. This is going to be one heck of a break-in. lol.

__________________

'89 RX7 GTU, half-Bridge-port S4/S5 NA, E6K, Full RB exhaust, weekend warrior. '83 RX7, The "this might take awhile" project. '87 RX7 GXL, Rest In Pieces. '98 Subaru Impreza Outback-sport, rx7 rescue vehicle, down for repair. '94 Ford Ranger, daily. Last edited by N.RotaryTech; 04-18-2011 at 09:30 AM. |

|

|

|

|

|

#53 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

My Turbo project!!!!

Ok, continuing what my previous post says about this turbo set up, let me get the pictures & details rolling.

Some picture sets might not be clear of the progression of things, I was more concentrating on building this project, but I think you'll get it. First the turbo setup I acquired.  (Post downpipe modification.) I started modifying the down pipe cause it was too long as to fit in between my RB silencer and the turbo.   As i took off the RB silencer the studs got fubared.  I ended up shortening the totally stripped stud, and cut away a thread or two of the other stud, cause the fastener I used was hanging up. This is what it looks like now.  I took it to a local car repair service center to get it welded together. Added the extra O2 sensor bung later. Future plan for this downpipe is to sand it down and cover it with hi-temp paint. |

|

|

|

|

|

#54 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

Next, I fabricated the intercooler mounting.

I didn't even have to move the overflow tank or the horn. I did reroute the coolant tubing though.  I painted it black.

|

|

|

|

|

|

#55 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

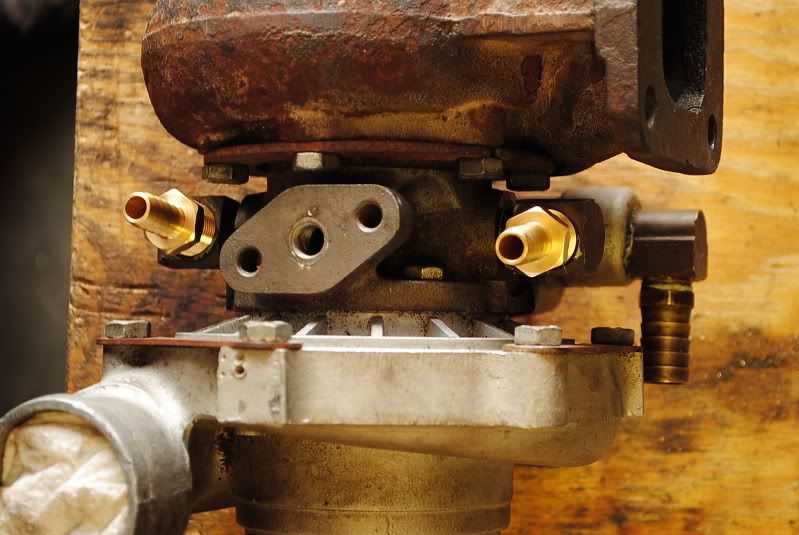

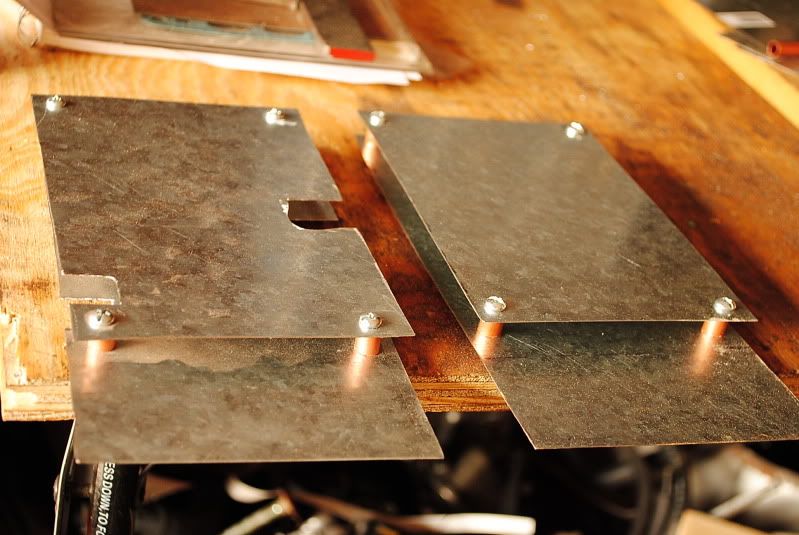

Changing the fittings on the turbo.

This is what i used for the oil feed line for the turbo. Parts from the plumbing section at Lowes. They are for Faucets.  Here I fabricated some heat shielding for the turbo.

|

|

|

|

|

|

#56 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

Intercooler piping. I used exhaust tubing from o'reilly auto parts.

Painted.  I modified an intake pipe from a Subaru Impreza and used it for the intake pipe for the turbo. I cut a lot of things off of it to fit and used epoxy to fill the holes and seams.   I cut apart my old cone air filter to make a filter element for the MAF sensor. A normal size filter wouldn't fit in the engine bay.   I installed 750cc injectors in the secondary's and rewired the connectors from S5 to S4.  Parts, gaskets, etc.

|

|

|

|

|

|

#57 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

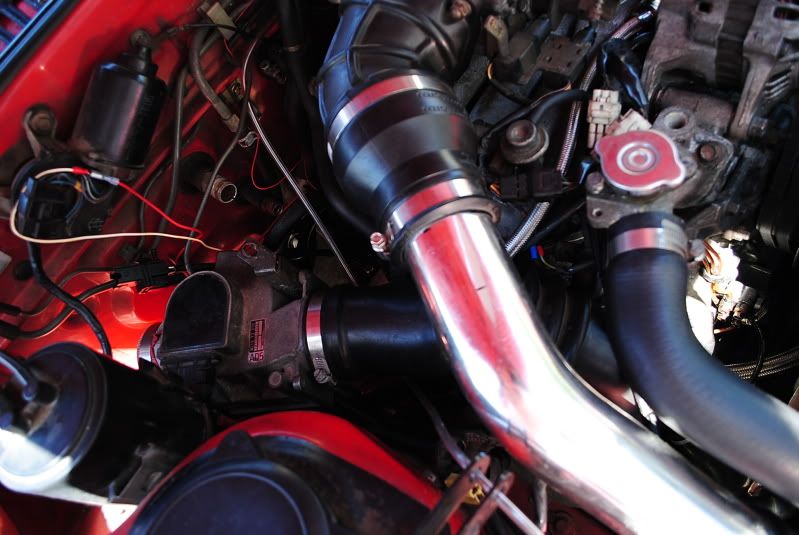

Finished project.

Kind of tight on the passenger side of the engine bay, but this is how things look.

I drilled a hole next to the radiator. Blitz BOV I traded some parts for. Used some clear tubing I had around instead of normal vac tubing which I didn't have.  The sun was killing this shot, but shows the IC piping.  The Subaru Impreza intake pipe installed.  I used an S4 turbo MAF sensor, changed the connector wiring, and have a piece of filter clamped on.  View from above the turbo. One of the heat shields, Oil and coolant lines installed. Also one of my attempts to fix an exhaust leak. I still have a leak.  Oil feed line and source.  Oil return.  Oil temp source via T fitting.

|

|

|

|

|

|

#58 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

And boost gauge, with a switch for the gauge light.

|

|

|

|

|

|

#59 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

Now for the details.

The turbo is a Turbonetics T3/T4 series, I forgot the specs, I wrote them down someplace, have to find that.

It has an external wastegate that apparently came with a 10 pound spring in it. 720cc (not 750cc as I posted before) injectors in the secondarys, with 6 ohm resistors installed inline with the wiring to them, actually located next to the ECU under the carpet. Stock Turbo AFM. Stock TII intercooler. Blitz BOV. The engine is the same as I posted before. S4, 9.4 comp rotors, mild porting on the housings and end-plates. And for the best part... All this runs on the stock S5 NA ECU! It will boost up to 10psi, but runs really lean up in that range. Around 5psi AFR's are perfect though. 11's and 12's Ive taken it for a drive / boosting just a handful of times. But found out last night after a drive that my Nopi stage 2 carbon kevlar clutch filled the engine bay with burnt/slipped clutch smell. So I might have to replace it after DGRR'11 I also found that the turbo's oil seals are bad, leaking through the exhaust and leaking externally. So with all this, I'm expecting a possible clutch, turbo & engine rebuild after DGRR'11.

__________________

'89 RX7 GTU, half-Bridge-port S4/S5 NA, E6K, Full RB exhaust, weekend warrior. '83 RX7, The "this might take awhile" project. '87 RX7 GXL, Rest In Pieces. '98 Subaru Impreza Outback-sport, rx7 rescue vehicle, down for repair. '94 Ford Ranger, daily. |

|

|

|

|

|

#60 |

|

Sigh.....

Join Date: Feb 2008

Location: Murfreesboro, TN

Posts: 2,377

Rep Power: 20  |

Any concern with those oil hoses not being made to withstand petroleum/heat?

__________________

1986 Sport: 132k miles, 5A (Sapphire Blue Metallic), Tokico Blues, Racing Beat Springs, Custom LED tailights (only S4 LED tails in the world), SSR Mark II, Racing Beat exhaust, S5 black interior, Rotary Resurrection rebuild at 120k miles Community Service Manual RotorWiki "Imagination costs nothing; we could build square locomotives or fly to Mars" - Felix Wankel Yesterday is history, tomorrow is a mystery, but today is a gift. That is why it is called the "present." |

|

|

|

|

| Bookmarks |

|

|