|

|||||||

| Rotary Tech - General Rotary Engine related tech section.. Tech section for general Rotary Engine... This includes, building 12As, 13Bs, 20Bs, Renesis, etc... |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| Rotary Tech - General Rotary Engine related tech section.. Tech section for general Rotary Engine... This includes, building 12As, 13Bs, 20Bs, Renesis, etc... |

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

Rotary Fanatic

Join Date: Mar 2008

Location: Brenham, TX

Posts: 335

Rep Power: 18  |

Oh I didn't know you were suggesting the turbine outlet of the SmallT would be dumping into the the LargeT. That would work fine then, the velocity would still be high enough to spool the LargeT. You do realize the compound turbos have wastgates too right? They are plumbed in the same manor you're talking about. Sounds like there is really no difference in operation for the exhaust side of what you're suggesting. And in both cases you still run into the problem of two exhaust housings/wheels in the stream of the exhaust which will increase back pressure/EGT, especially if the first is a small housing to help spool.

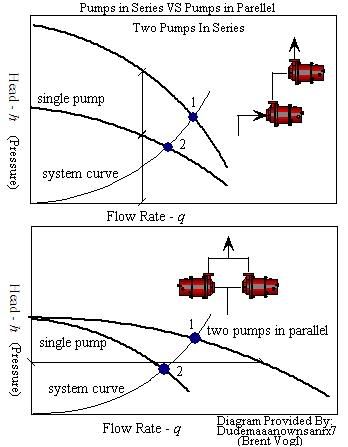

The only difference I see now, is the cold side. In a compound turbo the LargeT cold side feeds into the inlet (where the air filter goes) of the SmallT. This is where the compounding takes place. The boost is "compounded" or multiplied. While in a sequential system, there is usually a butterfly valve to keep the turbo that's "working", flowing only into the manifold, then the butterfly opens and allows the second turbo to contribute to the total volume of air, but it in itself would not increase boost pressure. The difference is much like the following diagram of 2 pumps in series vs parallel. Series would be compounding, and parallel would be sequential.  Here you can see the wastegate in the image below of a compound turbo.

__________________

500+ HP thanks to:  Fast reacting IAT sensor thread! Mechanical Pre-turbo Water Injection Thread Dual Stock fuel pumps Thread T2 differential swap! |

|

|

|

|

|

#2 | ||

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

Quote:

Quote:

EDIT: Just saw your direct comparisons, care to elaborate on those plots?

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group |

||

|

|

|

|

| Bookmarks |

|

|