All that's left is the gear and shaft assembly itself. The next step in the process is to remove the rear bearings and the 5th and reverse gear assembly allowing the mainshaft and countershafts to be removed, which then frees 4th gear.

Note: bearings may be with or without dust shields. My RX-7 had them on on both rear bearings but the Miata (shown above) doesn't despite being newer.

Note: bearings may be with or without dust shields. My RX-7 had them on on both rear bearings but the Miata (shown above) doesn't despite being newer.

First remove the countershaft rear nut and bearing to get them out of the way of the mainshaft pieces. In order loosen the nut lock the transmission into both 1st and reverse by sliding the respective clutch hubs into position. This allows you to apply torque to the rear nut without the transmission spinning. The nut is staked so you will need drive that out with a punch or screwdriver. The nut is also installed with a lot or torque so clamp the assembly down and use a breaker bar. Once the nut is removed the bearing can be pulled off with a normal two- or three-jaw puller.

Next is the mainshaft rear bearing. First remove the c-clip.

Then the small spacer behind it.

This exposes two thick c-shaped washers held by a retaining ring. Remove these to get to the mainshaft rear bearing.

Assembly note: keep track of the spacer and c-shaped washers. They are specific thicknesses and are needed to set the clearance for the rear bearing (see FSM).

Assembly note: keep track of the spacer and c-shaped washers. They are specific thicknesses and are needed to set the clearance for the rear bearing (see FSM).

Here is where the first SST comes in. The actual Mazda SST is a bearing puller with very long arms. Since I don't have access to these SST's I had to get creative. Fortunately I stumbled across a fellow forum member who went through this same process and came up with his own SST: a modified, two-jaw puller:

Basically, it's a simple two-jaw puller with the normal arms replaced by long steel flatstock. I forget the actual length but I think somewhere around 17 inches was required. With this tool the bearing is removed exposing another set of c-washers and retaining ring and it allows access to the countershaft 5th gear companion.

The countershaft gear slips off easily revealing a long tube spacer.

Remove the tube spacer but leave the countershaft reverse gear in place as it's required to keep the assembly from spinning. Jump back to the mainshaft and remove the c-washers and retaining ring that were behind the bearing. This exposes a thick spacer.

Assembly note: as with before keep these c-washers and spacer straight as they're needed to set proper clearances.

Assembly note: as with before keep these c-washers and spacer straight as they're needed to set proper clearances.

The spacer slides right off but like the speedometer drive gear it also has a small steel ball underneath it.

Assembly note: keep track of that spacer!

Assembly note: keep track of that spacer!

Now 5th gear and its syncho can be removed. They should slide easily off the mainshaft. Be careful not to mar any surfaces especially the synchro!. If you removed the assembly from the vice like I did you'll need to get it back in there for the next step.

With 5th gear gone the notorious transmission rear nut is exposed. Here is where SST number two comes into play. The actual SST is a very deep-well 32 mm socket. Again, I don't have access to one so I got creative. The same forum member came to the rescue with a hacked and spliced 32 mm socket and tube.

This nut is held on with even more torque than the countershaft nut so expect to spend some time here.

Note: I had an even more difficult time torquing the nut during reassembly because the Miata reverse gear is helical. This meant every time I tried to torque the nut the countershaft reverse gear would try to walk its way out allowing the mainshaft to spin. The RX-7 reverse gear was straight cut so there was no forward or rearward forces trying to move the gear. I find it interesting not only is the reverse ratio different but the cut is as well.

With the nut off the 5th/reverse clutch hub is exposed. Using the same long-arm puller above lock onto the hub being careful not to damage the brass syncho on the other side and remove.

Note: during the disassembly process I found it easier to disassemble the clutch hub while it was on the mainshaft. This gave more surface area to grab with the puller. I will explain the disassembly of a clutch hub at the end.

Note: during the disassembly process I found it easier to disassemble the clutch hub while it was on the mainshaft. This gave more surface area to grab with the puller. I will explain the disassembly of a clutch hub at the end.

Now the reverse gear and its syncho can be removed. Unlike 5th gear, reverse has a needle bearing and inner bearing race underneath it. Needle bearing:

Inner race:

Inner race removed:

Note: there is also likely a spacer between the reverse gear and the middle bearing. Remove this and keep track of it as it's needed to set clearance during reassembly (see FSM).

Note: there is also likely a spacer between the reverse gear and the middle bearing. Remove this and keep track of it as it's needed to set clearance during reassembly (see FSM).

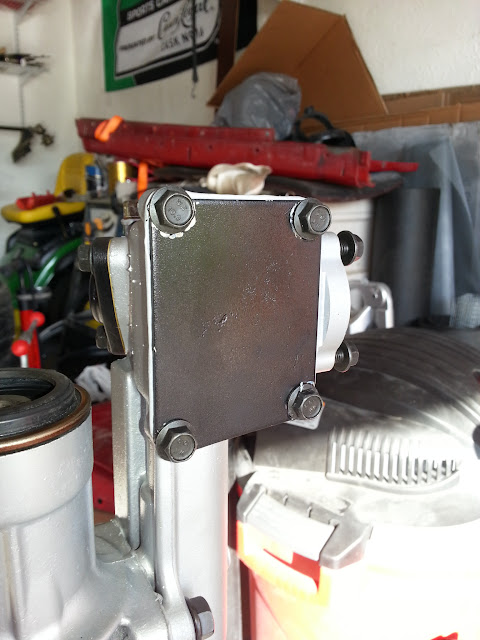

Next is the countershaft reverse companion gear. When trying to remove this gear I noticed the bearing plate cover interfered so I had to remove the cover. In order to remove the cover undo the bolts and pull it off. With the cover removed the countershaft reverse gear can be removed along with the idler gear and its two spacers.

Note: I don't believe the RX-7 FSM says the bearing plate cover has to come off. It's possible the different reverse ratio of the Miata makes this not possible where it is with the RX-7. Either way, don't forget to keep track of the spacers for the idler gear.

Note: I don't believe the RX-7 FSM says the bearing plate cover has to come off. It's possible the different reverse ratio of the Miata makes this not possible where it is with the RX-7. Either way, don't forget to keep track of the spacers for the idler gear.

Now the mainshaft and countershaft can be separated from the bearing plate. Both have to move together to be removed. In my case the mainshaft separated easily but the countershaft didn't want to budge. I ended up having to use the puller to "pull" the bearing plate off the countershaft and even then the bearing was still stuck on the countershaft. Keep track of any spacer on the forward side of the bearing plate as it works with the previous rear spacer to set clearances. Be careful once the three are separated as 4th gear and its synchro are no longer supported and can simply fall off the mainshaft.

4th gear slides off the front of the mainshaft easily. Be sure its syncho and needle bearing come with it.

Exploded:

At this point the transmission has been reduced to this:

Note: there are lots of specific spacers and washers that are removed during this step. Keep track of them and their location for reassembly. If you are replacing parts (I did not) different thicknesses are offered to properly set bearing clearances.

Note: there are lots of specific spacers and washers that are removed during this step. Keep track of them and their location for reassembly. If you are replacing parts (I did not) different thicknesses are offered to properly set bearing clearances.

Linear Mode

Linear Mode