Turbocharge your cooling system - SakeBomb Garage Competition Electric Water Pump Kit

The coolest thing to happen to the RX7. Ever.

If Mazda used a setup like this from the factory, countless motors could have been saved from overheating, warped housings, overheated and failed coolant rings, cooked turbos, and general rotary related heat woes. We've been revising this kit for over 8 months and are very excited to finally make this available to the FD community. Please forgive our lengthy thread, there is a ton of information to cover and we are doing our best to provide all of the necessary details and information in as readable of a format as possible. Please ask any and all questions, we expect quite a few considering the new technology.

Cliff Notes:

Cliff Notes:

Sustained coolant flow after shut down - Electronic controller allows pump to continue circulating coolant through your engine, radiator, and turbos after shutdown - prevents hotspots and boiling, and will even activate fans if needed.

Flow optimized and contoured SakeBomb Garage Coolant Redirection Plate - Redirects coolant flow in place of mechanical pump with minimal turbulence.

Efficient at all RPMs - Coolant pump no longer dependent on engine speed, so the pump is always flowing at optimal rate. Flow speed is now based on temperature, not RPM;

User programmable pump controller - Pump speed is increased or decreased based on engine temperature. Real time control of pump speed to reflect engine cooling demands. Programmable set-points for maximum temperature and fan control. Mil-spec wire used on essential under-hood components. (optional LCD display controller available)

Controller can trigger fans - removes the need for upgraded thermosensor (such as FC thermosensor).

No mechanical drag on motor - 2-7hp (conservative estimate) regained by removing parasitic drag on motor. Increased throttle response.

Increased reliability - Water pump belt slip is no longer a worry. No wax-pellet thermostat to fail.

Goodbye turbo timers! Pump circulates coolant through turbos after shutdown.

Low power draw - 8 amps at full speed.

Easy to bleed cooling system - Without car running, just connect pump directly to a 12V battery. Pulse pump to bleed.

-> Optional LCD Controller Upgrade <-

-> Optional Custom 'Samco' Silicone Hose Kit <-

*Kit Requires removal of airpump, thermostat, and mechanical water pump. No wax pellet thermostat, so your car may take a few minutes longer to warm up, however the pump controller handles thermostatic functions based on temperature by varying pump speed (short pulses for pump at startup until operating temp is reached. (Upcoming "street kit" allows retention of mechanical thermostat, and stock airpump.)

The OEM pumps are (for lack of a better term) garbage, with the impeller made from folded sheet metal. Up until this year we've been using the remedy machined mechanical pumps, however no impeller can be designed for optimal flow at all RPMs... you either under flow at low RPMs or cavitate at high RPMs. There is no one design that is optimal from 800-8000 RPM. The issue is that the pump (being mechanically connected to the motor) operates regardless of temperature and is forced to spin outside of its optimal range.

For example, if youre overheating but your motor speed drops, youre now moving less coolant when you need it most. Temperature, load, and RPM all become irrelevant factors with a mechanical pump tied to the crank pulley, its just along for the ride. The mechanical pump is forced to spin at the speed of the motor, and robs power to do it regardless of how much or little that pump really needs to be working. If we look at optimum pump speed, for a given condition the mechanical water pump is either under or over-cooling, under or over-spinning, or not spinning at all when you need it most (shutdown). Electric water pumps on the other hand can vary the pump speed based on the actual real time load demands for the cooling system and temperature of the coolant. It can spin as fast or as slow as required for the conditions to maintain the optimal engine temperature. New OEM applications tend to favor electric water pumps for a number of reasons, one being efficiency (no drag on the motor) and low power consumption (this one takes 8 amps max at full speed, and less as needed), but allows for other possibilities such as continuing to circulate coolant through the motor, radiator, and turbos after shutdown. The controller module we use also has the ability to trigger the fans if the temperature set point is exceeded after ramping up the pump speed. Its an elegant solution and may end up rendering the mechanical water pump system in the FD a thing of the past.

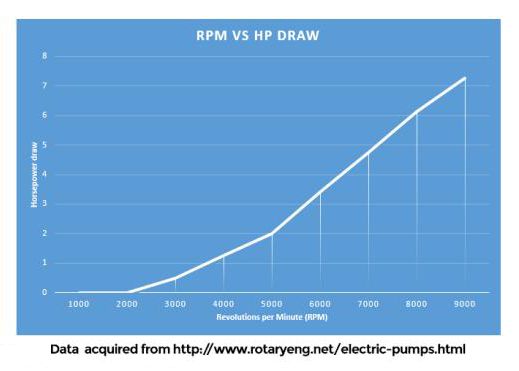

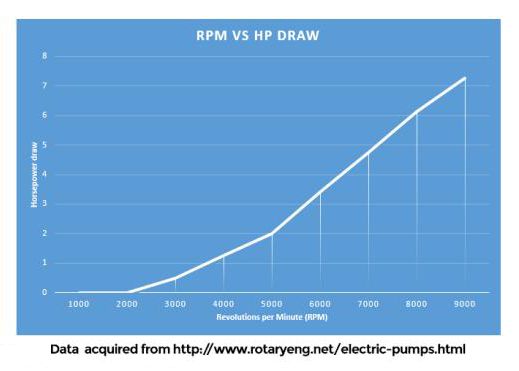

Estimate of hp loss due to parasitic drag of mechanical pump (2-7hp loss depending on RPM - conservative estimate)

Prevents heat soak

Estimate of hp loss due to parasitic drag of mechanical pump (2-7hp loss depending on RPM - conservative estimate)

Prevents heat soak

o Runs after key-off to continue circulating coolant through the motor, turbos, and radiator this prevents hot spots and boiling

o Electronic controller can trigger fans as needed to further cool the engine after ramping up pump speed - even while the car is off

o Coolant flows through turbos after shutoff - turbo timers are now redundant

o Pulls very little power (only 8 amps at maximum flow)

o Helps save turbo seals, coolant o-rings inside the motor, and prevents warping and hot spots from lack of cooling after shutoff

Maximum Cooling Efficiency

o Highly efficient impeller design - Optimized for maximum flow efficiency

o Standard mechanical OEM fitment pumps can be efficient either at high RPM or low RPM, but not both. Our electric water pump is de-coupled from the engine and is therefore efficient and effective regardless of engine speed.

Cooling On Demand

Cooling On Demand

o Electric water pump operation is based on coolant temperature, and controller can modulate the speed of the pump in real time based on cooling requirements.

o Controller temperature settings are customizeable.

o Fans can be activated by the controller to increase cooling if temperatures continue to increase after max speed of the pump is reached. This is essentially a digital version of the "thermosensor" which is user-programmable.

o Belt slip on the mechanical water pump pulley is now a thing of the past!

o The end result of the system is the ability to activate maximum cooling even at low RPM, and after key-off.

Free Up Power and Throttle Response

o Save horsepower and increased throttle response by removing parasitic drag of mechanical water pump on the engine. 2-7hp depending on RPM.

o Only draws a maximum of 8 amps at full speed, and less as needed.

Contoured Design Tested for Optimal Flow

o 3D-optimized and contoured billet 6061 aluminum coolant redirection plate, milspec hard anodized.

o Contoured fluid path to drastically reduce turbulence and vortices forming in the water pump housing with the mechanical water pump removed

o Months of flow testing and revisions to create bowled output to fluid passage; this reduces turbulence by preventing quickly moving coolant from hitting a flat wall rather than smoothly directed towards the coolant inlet. The smooth flow contour aims to achieve as close to truly laminar flow as design constraints allow. Less turbulence means less flow restrictions and therefore more efficient and effective cooling.

o The plate has a C-ring that seats in the same beveled surface that the mechanical water pump blades do, forcing coolant through the flow path to the motor rather than whirl around and create turbulence.

Direct Mounting Location

Direct Mounting Location

o Located in lowest possible orientation to aid in most effective pump operation.

o Short and direct flow path to radiator.

o Electric water pump allows easier bleeding of coolant system. Connect pump directly to a 12V power source to manually circulate coolant through the engine without the caron. (With a manual pump, it usually takes days of topping up the system and heat cycling to thoroughly remove all air)

Specs

Specs

40 gallon per minute maximum flow rate

72.5 psi maximum rated operating pressure

8 amp maximum current draw

Recommended operating range of -40°F to 266°F

Aluminum pump housing for improved durability

7000+ hour manufacturer rated lifespan; equates to roughly 200,000 miles at an average of 35mph

2 year pump warranty

- DGRR 2011 Peoples Choice - April 2011 Rotary of the Month

- DGRR 2011 Peoples Choice - April 2011 Rotary of the Month

Linear Mode

Linear Mode