|

|

#121 |

|

Rotary Fanatic

Join Date: Mar 2008

Location: Brenham, TX

Posts: 335

Rep Power: 18  |

The sensors can be ordered from my site. Wannaspeed.com.

You will need to add either pigtail wiring, or the plug n play harness for the FD. I currently only have 1 pnp harness in stock, but I have ordered more and will be here in a week or so. The pigtail version requires splicing into the factory harness.

__________________

500+ HP thanks to:  Fast reacting IAT sensor thread! Mechanical Pre-turbo Water Injection Thread Dual Stock fuel pumps Thread T2 differential swap! |

|

|

|

|

|

#122 |

|

cxxxx|::::::::::::>

Join Date: Nov 2009

Posts: 315

Rep Power: 17  |

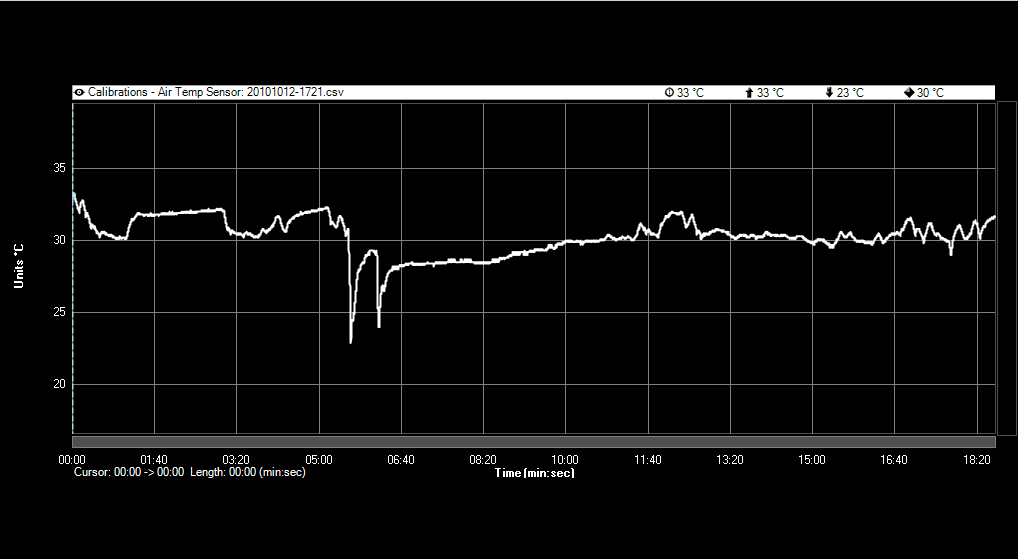

Here's a data log of this thing in action when 100% methanol comes on

|

|

|

|

|

|

#123 |

|

Five slice baloney

Join Date: Sep 2010

Location: CA

Posts: 10

Rep Power: 0  |

wow tyler that 500~640 transaction is huge !

|

|

|

|

|

|

#124 | |

|

The Judge

Join Date: Feb 2008

Posts: 196

Rep Power: 18  |

Quote:

I added an inline resistor to compensate for this at the air temperature range which my engine sees the most in Texas. Thus for summer it is dead on and only off a little for winter. |

|

|

|

|

|

|

#125 |

|

The Newbie

Join Date: Dec 2008

Posts: 28

Rep Power: 0  |

Any chance I can get added to the waiting list? Out of stock on the website!

|

|

|

|

|

|

#126 |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 18  |

word of warning on these sensors for you people who actually drive your cars!

These sensors WILL fail after around 10,000km of use. Because of the exposed element and the pulsing nature of the rotary engine (and maybe the effect of over 30psi intake manifold pressure!) the sensor wires DO fatigue and break resulting in the AIT sensor going open circuit (showing -40 deg C lol) ..... I have seen this happen over 2 of these sensors now, but unlike most I do actually drive my rotary daily! and do allot of testing kilometers !!! I have another supplier in the U.K. who sells a slightly different version of this open AIT sensor and I am doing durability trials on these across a various range of customer cars and mine as well. Will update when we accumulate some more real world testing

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration |

|

|

|

|

|

#127 | |

|

Rotary Fanatic

Join Date: Mar 2008

Location: Brenham, TX

Posts: 335

Rep Power: 18  |

Quote:

__________________

500+ HP thanks to:  Fast reacting IAT sensor thread! Mechanical Pre-turbo Water Injection Thread Dual Stock fuel pumps Thread T2 differential swap! |

|

|

|

|

|

|

#128 | |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 18  |

Quote:

The sensors failed exactly as I described! hence I posted about it! If you don't cover as many km's like most rotary owners then I agree you wont fatigue the wires. It's pretty easy to see it happen, and no heat gun is needed! I can show you a computer data log showing exactly how many hours the sensor was used and the highest temperature recorded off it if you are still indoubT ! NO NEED TO BE A **** A SLUR MY FACTUAL TEST AND WARNING TO OTHERS AS BULLSHIT THANKS!!!

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration Last edited by RETed; 09-20-2011 at 09:22 AM. Reason: no need for vulgarity |

|

|

|

|

|

|

#129 |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 18  |

P.S. I don't sell the other sensors either BTW!

They will most likely fail as well in time due to being weak open element types too! There is a reason Mazda did not use these in the rotary engine and I can see why now after accumulating allot of testing hours and time and kilometers on them. The same fatigue happens to open element EGT wires as well for your information, and no I dont sell others ether of those. Just passing on real knowledge and testing which fuck all other people do or have the ability or running cars to do so.

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration |

|

|

|

|

|

#130 |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 18  |

In the rotary engine especially the 13B-REW with its dynamic chamber intake manifold and where the AIT sensor is placed it sees large "pulses" and these over time flex the sensor wire back and forth, you need to do many km's like I stated in my first post, and I guarantee you this will fatigue the wire or wires and it will go open circuit.

I have see this happen in egt sensors and also in these AIT sensors (if you sell them or not is not my issue nor my aim to warn people@) its just that this type of sensor WILL fail in a rotary engine over time. Typically its happened on 2 different cars at around 10,000km covered range. both 13B-REW's with stock intake manifolds and positioned sensors. Take that for what you will. The sensor tips did not fall off into the motors but one wire on each sensor was broken due to the constant flexing the exposed sensor tip is subjected to. And as I stated its a well known fact that open element EGT sensor tips suffer the same failures due to pulsations breaking wires as well. When the sensor goes south least the motor will run rich if you have the ECU set up correctly for it.

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration |

|

|

|

|

|

#131 |

|

Rotary Fanatic

Join Date: Mar 2008

Posts: 104

Rep Power: 18  |

Were the failed sensors placed in the UIM or relocated? I think most using them here have relocated it to the post-intercooler piping.

Jack |

|

|

|

|

|

#132 | |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 18  |

Quote:

All of these types are very flimsy compared to the stock reliable piece, you can simply touch the junction and they flex with the slightest pressure applied. Based off that the UK sourced ones will fail @ the same rate if I were to guess but you don't know until you do the testing hours. I'll report back when I do.

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration |

|

|

|

|

|

|

#133 |

|

Rotary Fanatic

Join Date: Mar 2008

Location: Brenham, TX

Posts: 335

Rep Power: 18  |

Saying they WILL fail at a certain mileage with your limited experience with the sensors seems presumptuous to me. You only ordered the sensor from me about a year ago, and given that I've moved over 400 of these in the last few years and have been in contact with the customers and rotary shops all around the world that have installed the sensor and have had nothing but good things to say is evidence of the quality of the sensors. See when something is deemed doomed to fail as you put it in your post then you hear bad things not good things. More people are anxious to post their negative results in using a product rather then their good results. So I'm very shocked for you to claim seeing 2 of these fail when I'm fairly certain I've had much more experience with them.

Saying something WILL fail at xx miles is a bold claim and I'm sure many members on this board can also attest to a fully functional sensors beyond those miles. Personally I put about 8k miles on my car every year so I'm beyond the point at which my sensor was supposed to fail according to you. (stock location) Must be lucky I guess. Also, it seemed to me you were in the beginning stage of selling the sensors yourself or recommending a particular source that is affiliated with you, so I thought maybe your intentions were motivated by $ signs. Anyways that's unfortunate you had such bad luck with the sensors I've never seen that before. Strange

__________________

500+ HP thanks to:  Fast reacting IAT sensor thread! Mechanical Pre-turbo Water Injection Thread Dual Stock fuel pumps Thread T2 differential swap! Last edited by dudemaaan; 09-18-2011 at 08:22 PM. |

|

|

|

|

|

#134 |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 18  |

Yes I see your points.

For me remember I have covered ~10,000km in less than a year  remember daily driver. This is why I don't quote "time" it's rather what you do in that time that is much more important. Also the cycles from cold to hot, true street use all has an effect, rather than just getting in and covering 10,000km straight........... bit like rotaries passing bench tests NSU/Mazda style then failing at 1/3rd the distance when use in the real world by owners and not in a laboratory remember daily driver. This is why I don't quote "time" it's rather what you do in that time that is much more important. Also the cycles from cold to hot, true street use all has an effect, rather than just getting in and covering 10,000km straight........... bit like rotaries passing bench tests NSU/Mazda style then failing at 1/3rd the distance when use in the real world by owners and not in a laboratory  Regardless, if you send me an E-Mail I will send back the failed sensor for you to see yourself on my own car, cause that is the one I can vouch for 100% myself in the time I used it and km's covered, happy to send you other matching information logging its use off the ECU as well. The sensors them selves look o.k. (build finish etc) but the bit I don't like on any of them is how weak and flexible the "element" is, it is easy to see how it could fail in "time". Like I said its not an attack on you or for me to sell others etc, I have no interest in that at all, just so when they do break (some rotary owners will never ever reach 10,000km or more of true daily use) then you know that at least someone else has told you what the problem is. I do come across all kinds of similar things "that no one else has ever discovered"....... this is not the first time and def will not be the last I'd say based off experience.

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration |

|

|

|

|

|

#135 |

|

Sigh.....

Join Date: Feb 2008

Location: Murfreesboro, TN

Posts: 2,377

Rep Power: 20  |

(My5ABaby mentions something about not agreeing with RICE RACING conclusions here due to inadequate statistical proof. I've deleted all the discussion that does not have any direct discussion of the topic itself. Please keep replies on-topic. Thank you. -RETed )

__________________

1986 Sport: 132k miles, 5A (Sapphire Blue Metallic), Tokico Blues, Racing Beat Springs, Custom LED tailights (only S4 LED tails in the world), SSR Mark II, Racing Beat exhaust, S5 black interior, Rotary Resurrection rebuild at 120k miles Community Service Manual RotorWiki "Imagination costs nothing; we could build square locomotives or fly to Mars" - Felix Wankel Yesterday is history, tomorrow is a mystery, but today is a gift. That is why it is called the "present." Last edited by RETed; 09-22-2011 at 07:59 AM. |

|

|

|

|

| Bookmarks |

|

|