Holy Shit! Nearly 12 months since last update.

Well I've had a bit on the go with a few home projects, work, family and serious case of CBF at times.

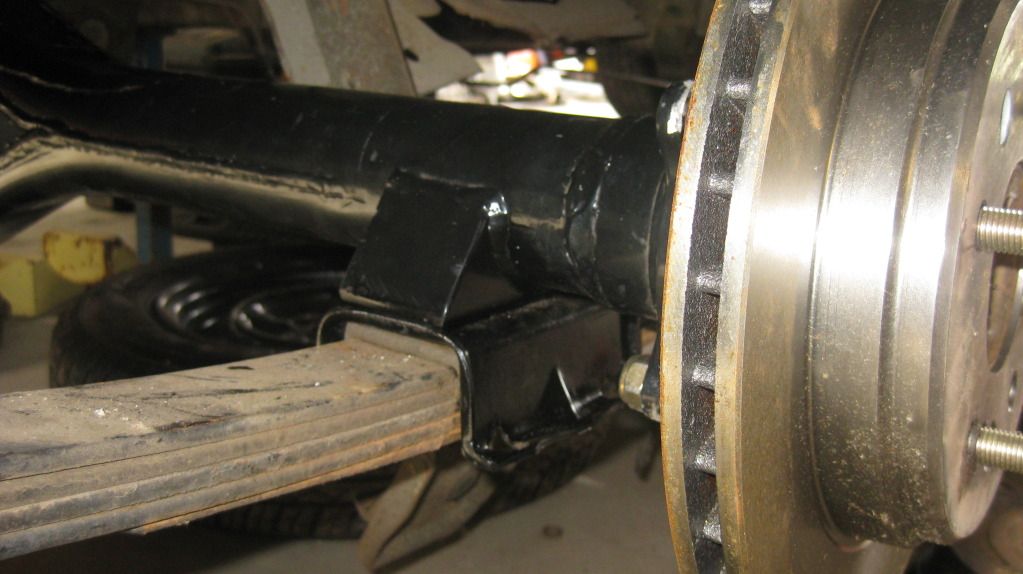

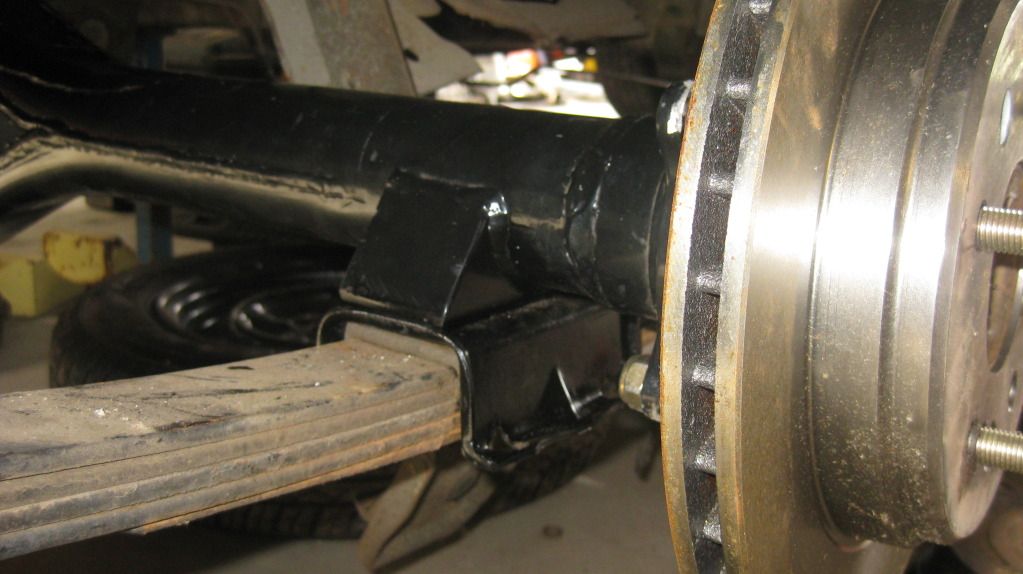

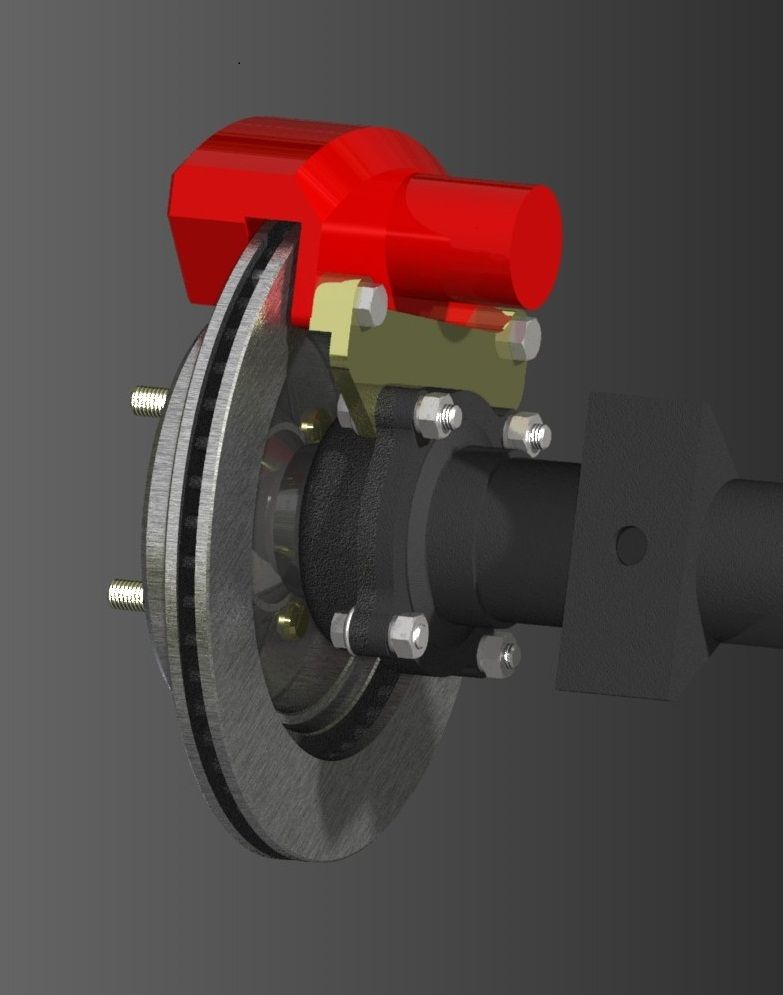

In the meantime I purchased a Toyota Hilux diff with the mounts already at the correct width for my RX4 with the axles machined and drilled for 4 x 110 studs and SV RX7 disks.

I removed the old diff and as you can see it was painted purple. Only on the rear side and over dirt, grease and grime.

I went to test fit the Hilux housing and found the holes used to locate the housing on the spring spigots was too small. :wallbash:

So off to the local tool supplier and bought a 29mm hole saw. I cut a hole in a scrap bit of flat bar and then tack welded centrally around the hole on the housing.

I took the center drill out of the hole saw arbour and drilled a larger hole in the spring mount.

I cleaned the spring saddles and repainted them.

Did the same to the otherside then test fitted the housing. Even got to see what my Simmons look like on for the first time.

Now I am planning to duplicate the factory diff torque rods and mounts fitted factory to some rare RX4s but with some adjustability.

) I got around to welding the exhaust probe bung in and shaping the dump pipe to give a bit more clearance for the steering box.

) I got around to welding the exhaust probe bung in and shaping the dump pipe to give a bit more clearance for the steering box.

.

.

Linear Mode

Linear Mode