Yep new stuff is always nice. I'm sure somethig will not get tightened the first go round and it'll leak on something lol.

I'm going to have to check every single nut and bolt on the car after assembly honestly. Some stuff I left hand tight on purpose, some stuff is tightend all the way.

So my some of my stuff arrived finally late in the day, got a bit more work done but then it started getting cold and I was hungry lol.

Installed the M10x1.0 to -3AN fittings in teh factory junction block.

Added the bulkhead just below the junction. This runs between the junction and eventually the output of the hydro ebrake.

That's where it is in the inside (Driver's storage bin area).

Finished up the left rear line.

Right rear line finished.

Installed the line clamps. I did reuse the factory plastic clamp in the right corner there, since it still worked fine. It also kept me from having to drill a hole through the first layer of trunk steel to find the inside of that little welded on bulkhead to get a nut on the backside. Also using a rivenut was out of the question do to space constraints. The tool can't fit in that awkward little corner.

Fits like factory, no biggie.

My new fuel filter. If it turns out to be inadequate in flow I'll just get a different one later. It's for fuel injection and supposedly flows fine for what i need. We shall see. It's only like $40 or something like that and has a replaceable element. Doesn't come with the -6AN fittings, you have to buy those seperately.

Had some 1-1/4" clamps left over from my wiring harness business, they fit pretty snug. You might even be able to get some 1-1/8" ones on if you wanted to try that hard.

Mounted her up near the factory location. Reused one factory hole and popped a rivenut in the frame for the other hole. Should be plenty of clearance there for the steering shaft and header.

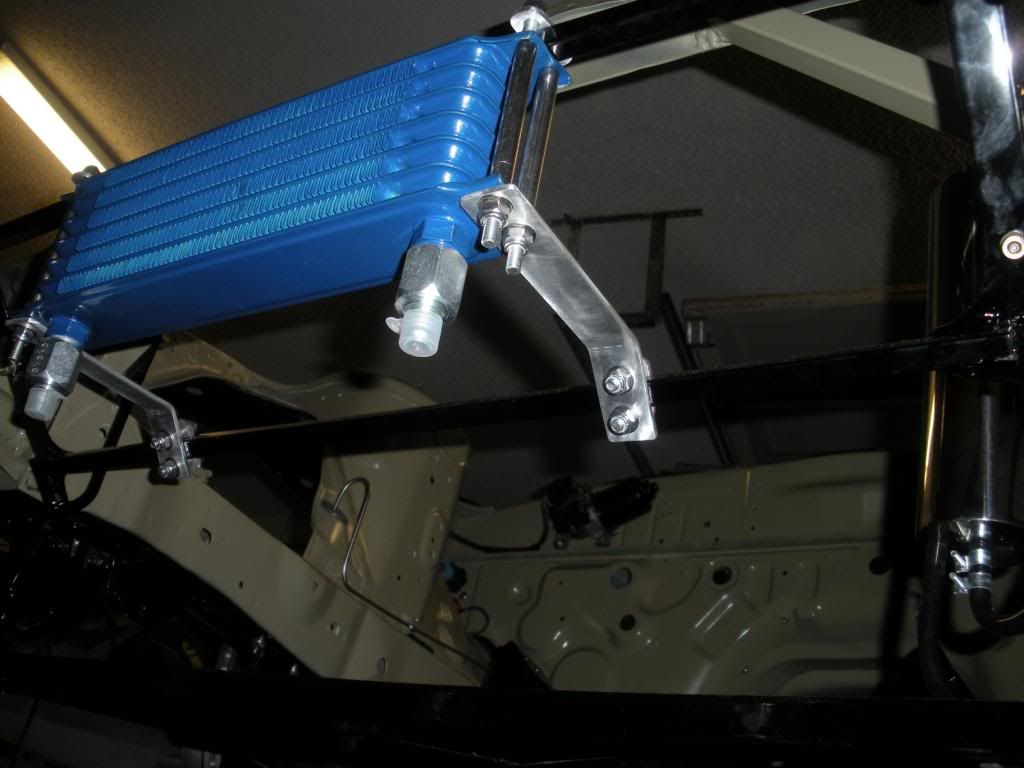

More rivenuts to mount the surge tank and second fuel pump. A bit of time was consumed on making that little humble looking hard line between them. Took a couple trys to get it right. It is the absolute smallest shape possible for both my tubing bender and my flaring tools (Imperial brand BTW). Just enough tube to grab with the sleeves pulled back all the way to be able to flare the ends. Probably could have just used a 90 degree long AN coupler or something but after failing the first attempt I decided it was going to happen whether it liked it our not.

Linear Mode

Linear Mode