This thread is intended to answer some questions about the function (or lack thereof) of the OE RX-8 fuel pump assembly as it is employed on the 2008 and earlier models.

There is a lot of speculation out there about pump efficacy, volume and the function of the siphon system for the saddle-style fuel tank as well as some pretty wild conjecture about the filtration parts, pressure regulation and the control electronics.

The fuel pump assembly is located under an access panel beneath the left-side rear passenger seat. The lower seat cushion simply pulls up and the panel beneath is held in place by 4 sheet metal screws. Since the pump is a "dead-end" style, self-regulating assembly, there is only a single discharge outlet and no return inlet. There is a single electrical connector on the pump assembly that provides power to the pump and readings from the left-side tank level sensor.

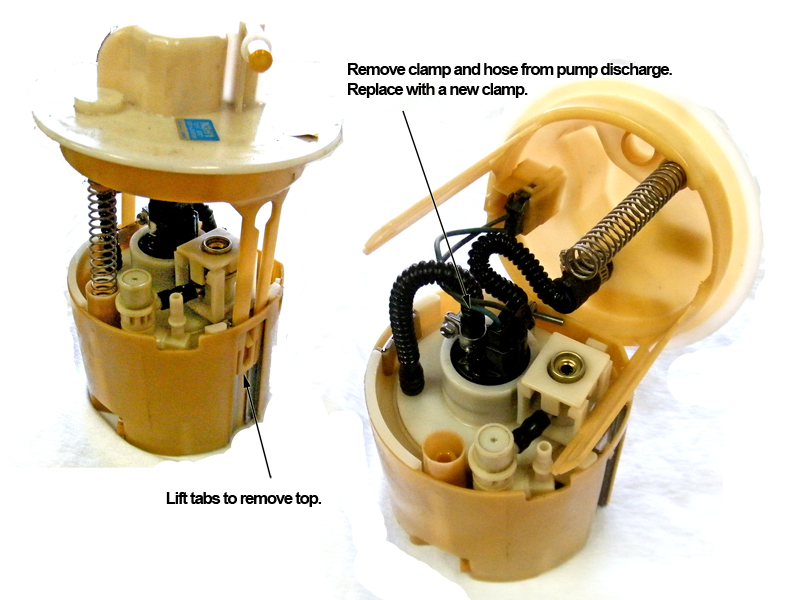

The pump assembly is mounted to the tank and held in place via a clamp ring that is removed with a "special service tool". This ring clamps the pump's upper section to the opening on the tank and against a stacked set of "O" rings.

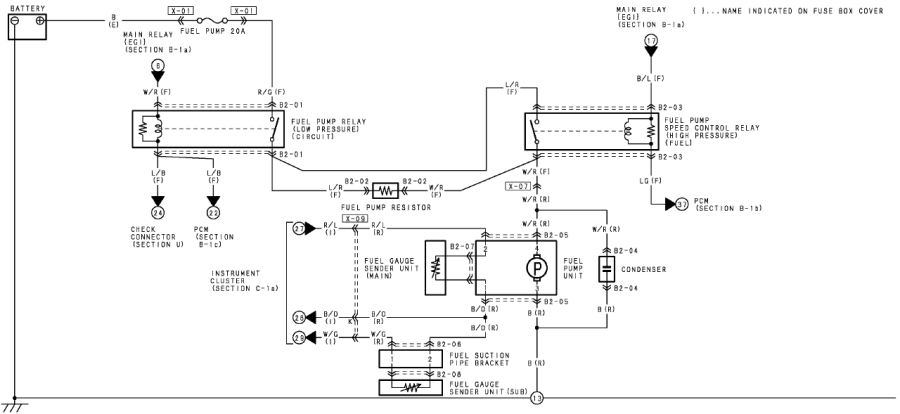

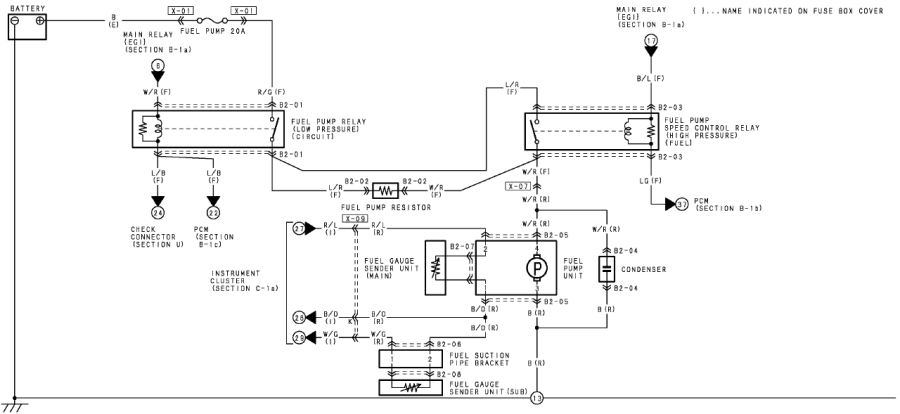

The pump is controlled by a "two-step" electrical regulation scheme under PCM control. Two relays in the main fuse box under the hood provide current to the pump in two stages - the initial low-load/start-up/idle output is on the "CIRCUIT" relay and the high-load output is on the "FUEL" relay.

Current from the "CIRCUIT" relay passes through a .34 OHM power resistor located on the air pump assembly bracket prior to powering the pump. This resistor lowers the pump voltage by about 2 volts from the alternator's ~14v output. Current from the "FUEL" relay goes directly to the pump, bypassing the resistor.

Under command from the PCM, these relays close based on current vehicle operating conditions.

The "CIRCUIT" relay is closed at all times that the engine is running or being cranked. It is open (off) when the key is in the "RUN" position and the motor is not running. It also switches off should the engine stop running for any reason or the roll-over sensor in the fuel tank is tripped.

The "FUEL" relay closes around the same time and conditions under which the secondary fuel injectors are enabled, upping the pump pressure output by about 15%.

This scheme is employed

purely to reduce noise from the pump and fuel vapor emissions and is

NOT a wear-reducing countermeasure. Most modern performance vehicles with an electric fuel pump employ this scheme.

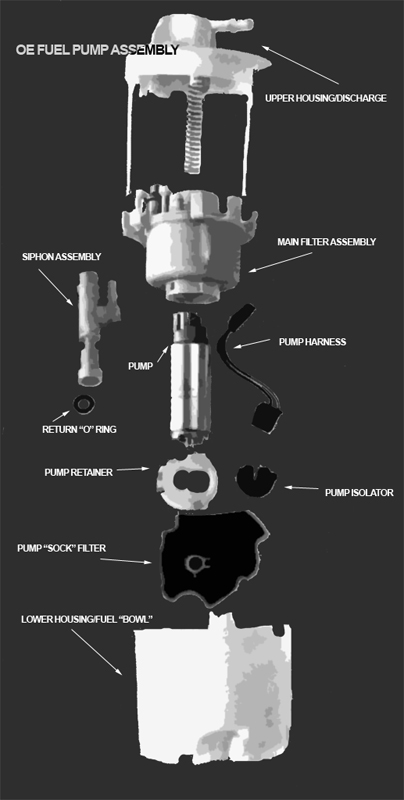

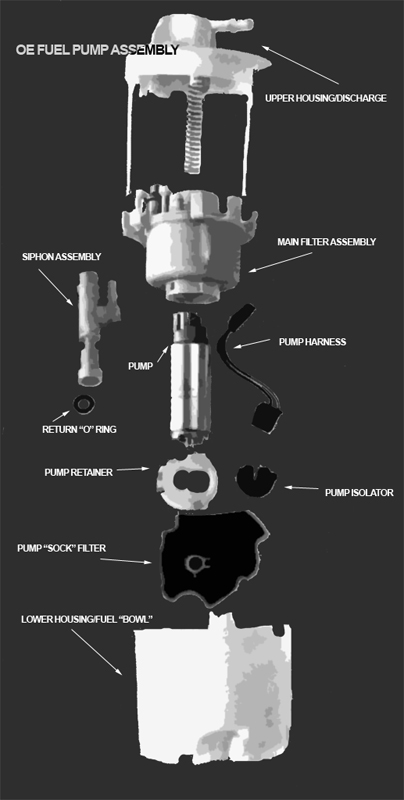

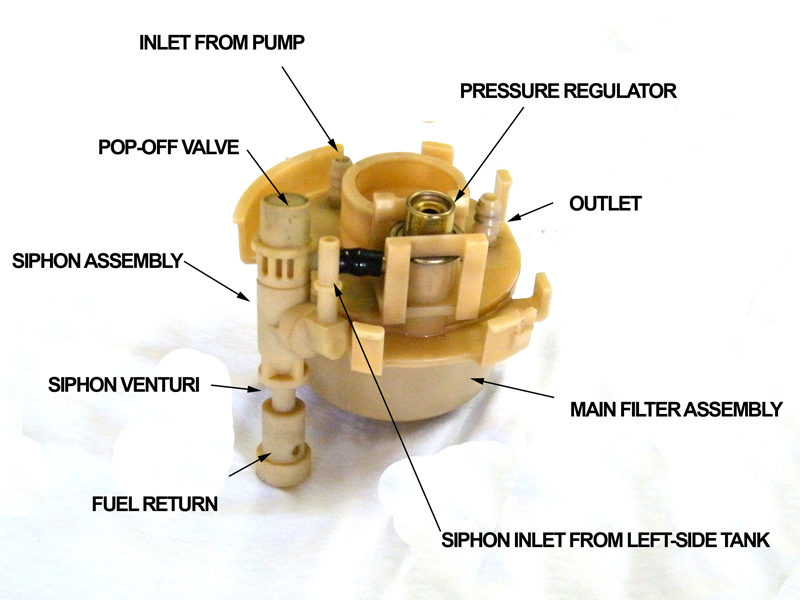

The pump assembly itself is comprised of 5 main components:

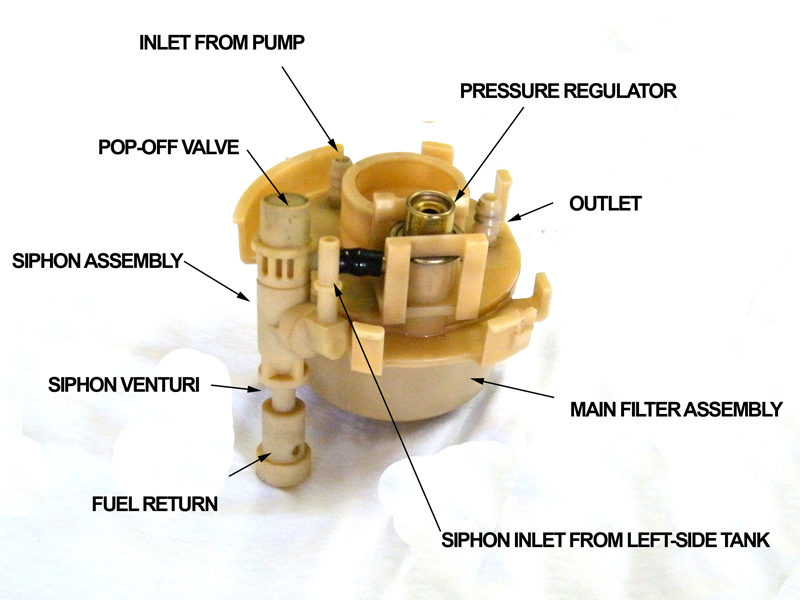

The spring-loaded upper section which has the discharge fitting and external connector, the lower fuel "bowl", which accumulates and retains fuel prior to being picked up by the pump, the pressurized main filter and integral fuel pressure regulator, the regulator discharge and siphon assembly and the pump motor itself.

The pump motor is a ~115 lph (nominal) unit made by Arram. When current is applied, it draws fuel in from its pick-up port on the bottom through a plastic filter "sock" that blocks larger particles of crud from entering the fuel system. The fuel is discharged from the upper port under pressure.

Pressure and flow are, of course, inversely proportional, so the volume of fuel that is moved by the pump is a function of the pressure developed after the pump. This pressure is regulated by the main filter and integral fuel pressure regulator, into which the pumps output is sent.

The main filter and integral fuel pressure regulator has three ports: the inlet, the outlet and the pressure regulator discharge.

Fuel is pumped into the main filter assembly and exits the discharge at a rate determined by the integral pressure regulator (about 60 PSI).

When the pressure inside the filter exceeds the regulator setting, fuel is sent back to the fuel bowl via the regulator discharge and siphon assembly.

Fuel passes through a venturi on its way back to the bowl, generating suction on the siphon tube fitting. If excess pressure is generated by the small venturi orifice, it is bled off through a spring-loaded pop-off valve on the top of the assembly.

This is, in a properly operating pump assembly, a continuous operation - fuel is always flowing out of the main filter and through the siphon assembly as the pump should be producing more than 60 PSI at the required flow at all times.

There are essentially 3 failure modes observed with this pump assembly:

1)Loss of flow during normal operation after extended highway cruising

2)Loss of flow during relatively high-G left-hand turns

3)Loss of flow during normal operation after 60k miles or more

Additionally, a drop in pressure may be noted during high demand and will adversely affect engine output and AFRs. Those tuning their PCM may note fairly extreme deviations from commanded fuel values at higher loads.

Though much has been discussed on this forum with regards to the causes of these failures - filter clogging, misalignment of the assembly in the tank, crimped or disconnected siphon hoses, clogging from the use of pre-mix, etc. - all can actually be attributed to partial failure of the pump motor itself.

In every pump I have tested - some that were removed because of these failures, some as regular maintenance and some that were still in service - the pump motor could not keep up with demand under all circumstances.

In many, the pump never produced enough pressure to open the regulator at all. This means that no fuel was servicing the siphon, so no fuel was being moved from the right-side tank to the left-side.

Not a single pump had enough "blockage" of either filter element to restrict flow were the pump up to task. In fact, the sealed main filter cannot restrict flow significantly even if it were somehow completely clogged! The assembly is constructed in such a manner that fuel will flow around the element as it becomes a restriction (something that NONE of the pumps tested had done - even units that were replaced for that very reason by the owner of the vehicle).

Solutions suggested to date:

1) Dismantle and clean the filter elements As noted, the main filter is not serviceable and wouldn't contribute to reduced pump output even if it became completely blocked. The "sock" on the bottom of the pump motor is serviceable, but none of the pumps I inspected were blocked. Some were dirty or contaminated, but offered no noticeable restriction to pump flow.

2) Replace the entire unit with a new OE unit So far the most practical solution. At ~$135, it is relatively easy and requires very little action on the part of the user. However, it does not address the under-performing pump motor itself and it will eventually fail again.

3) Replace the entire unit with a new 2009+ OE unit Also a good possibility. The newer pump system uses a superior Denso pump instead of the Arram and inverts the venturi/bypass mechanism function. At ~$250 or so, it is a bit more expensive and requires some wiring and placement of the pump in a manner that differs with its intended application and orientation.

None of these solutions address the fundamental issue that the OE pump is designed to just barely fulfill the fueling requirements for 250 - 300 HP and probably only does so for a short period of time. Additionally, the OE siphon system will only continue to work as long as the pump is surpassing the fuel demands of the motor. As soon as its output is below demand, the siphon will stop working again. If you are racing and in a high-G left hand turn while accelerating in a high-output RX-8, you will almost immediately starve the pump.

The 09+ assembly addresses some of the siphon issues, but is still designed to provide about 115 lph. A 350 HP+ Renesis will need closer to 200 lph.

Fortunately, the solution for

ALL fuel pump issues is relatively easy and inexpensive:

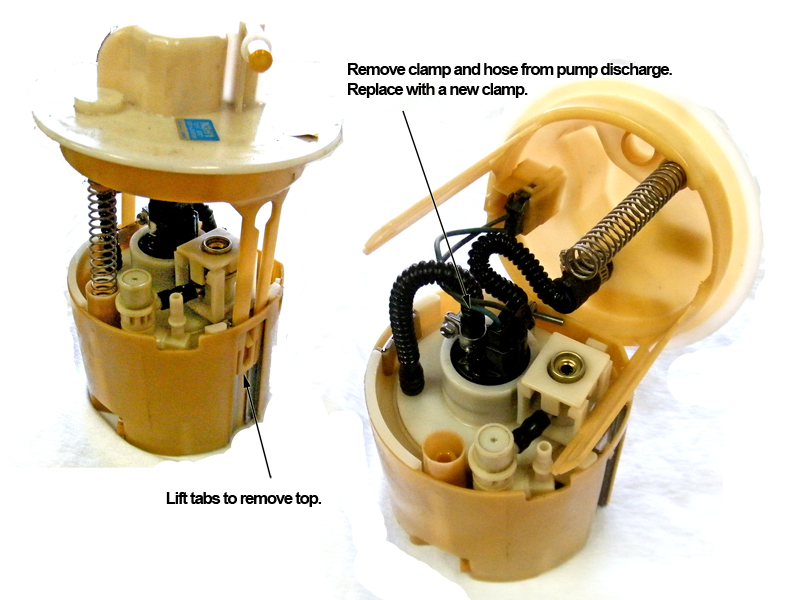

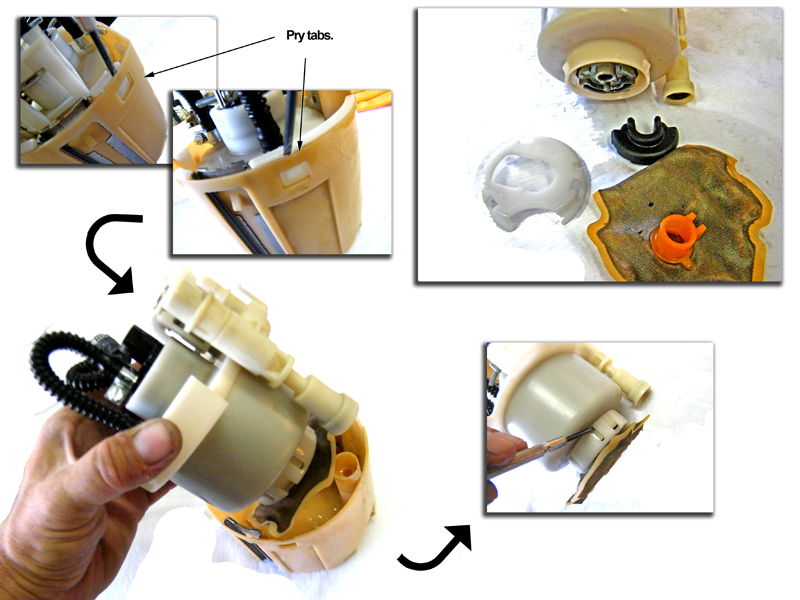

Simply modify the siphon assembly for greater flow and install a high-output pump motor.

The Walbro 255 lph pump fits into the OE housing perfectly, has the correct inlet and outlet, the same electrical connector and will provide enough flow and pressure for over

500 HP while still operating the siphon at all times.

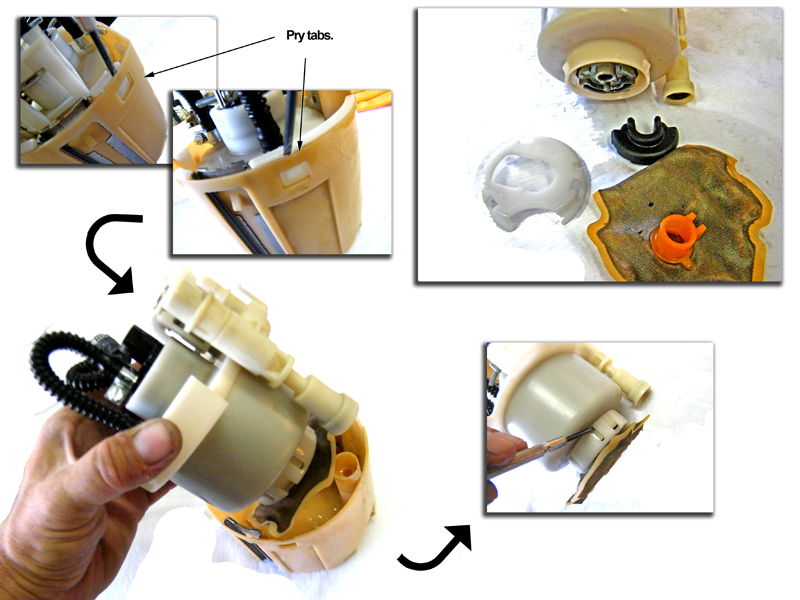

Just dismantle the OE housing, replace the pump with the Walbro unit and it is ready to go. You will need a new "O" ring for the top of the pump that is about 1/2 the thickness of the OE ring. They can be had a Ace hardware for about 30 cents.

To increase flow through the siphon, just drill the venturi orifice out to 1/8" through the fuel return outlet (you should only do this with the upgraded pump and it

MUST be done with the Walbro to avoid blowing open the pop-off valve at all times, reducing flow and cavitation of the pump assembly) and reinstall.

The Walbro pump can be had for about $90. Just be sure you get a real Walbro - there are quite a few Chinese copies out there that are horrible. Be sure to only purchase from a reputable distributor.

Linear Mode

Linear Mode