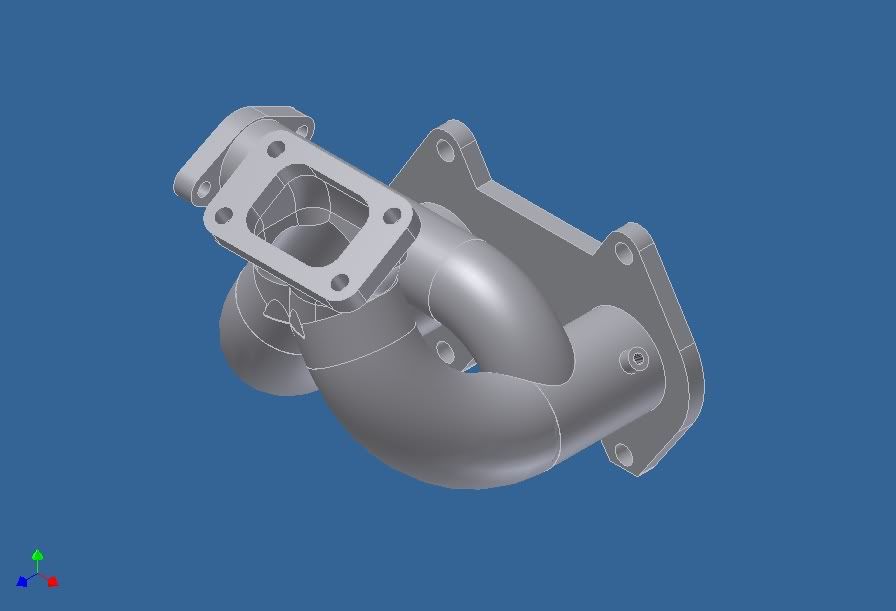

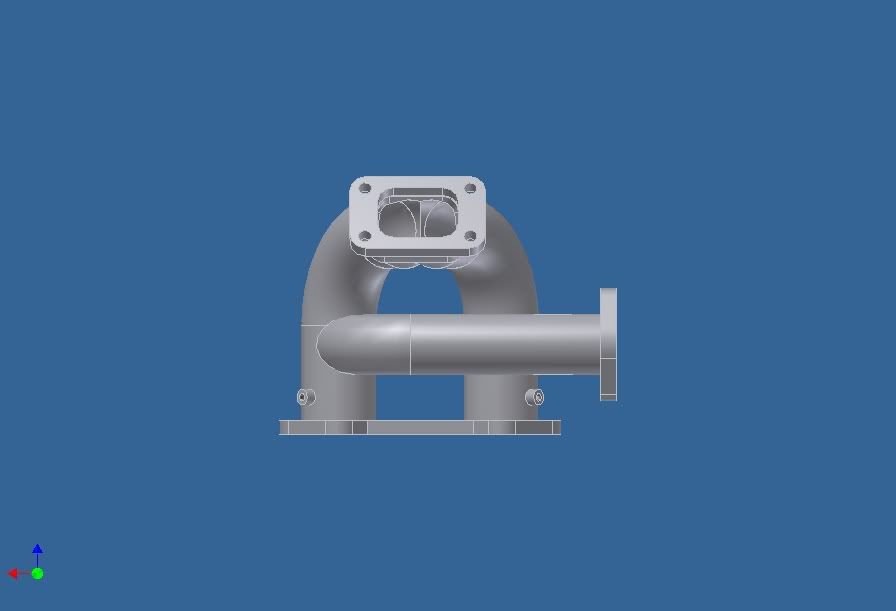

So by now you have a majority of the manifold constructed (and I emphasize a majority), you should realize that you need to know how the turbo needs to sit and what room you have left. So throw on some of the intake and check your clearances, like so:

Notice that it's a tight and snug fit, and depending on where you mount your turbo you may have more or less (more with a smaller turbo, less... and probably having to cut into the sheet metal to mount the nice big turbo you have).

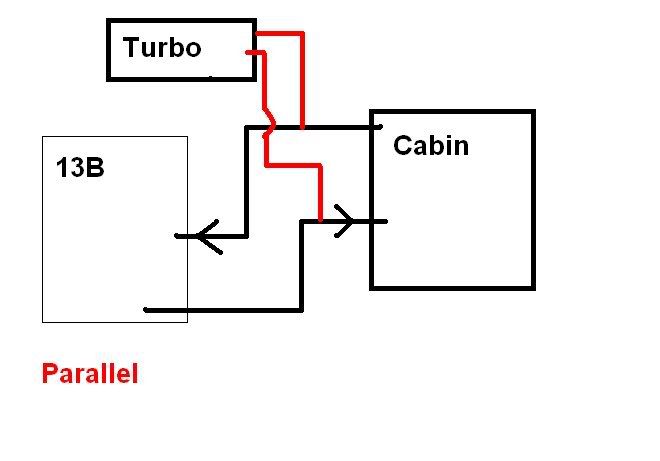

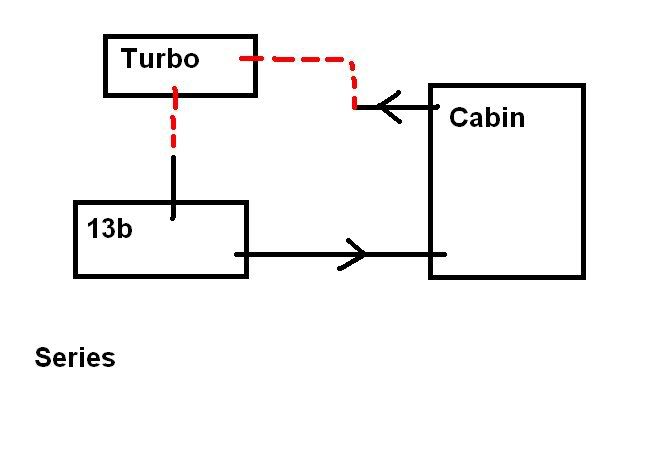

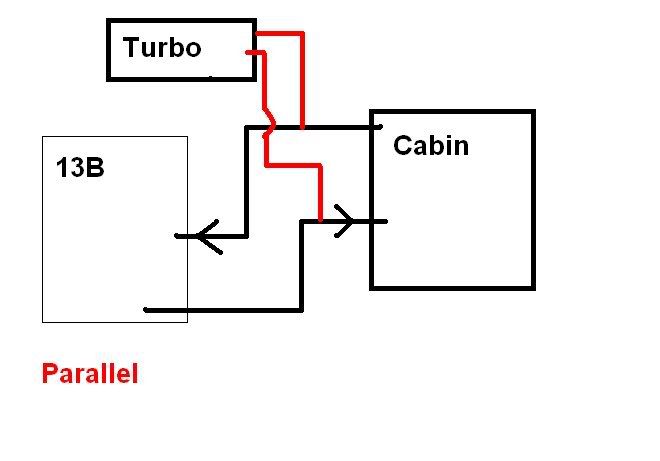

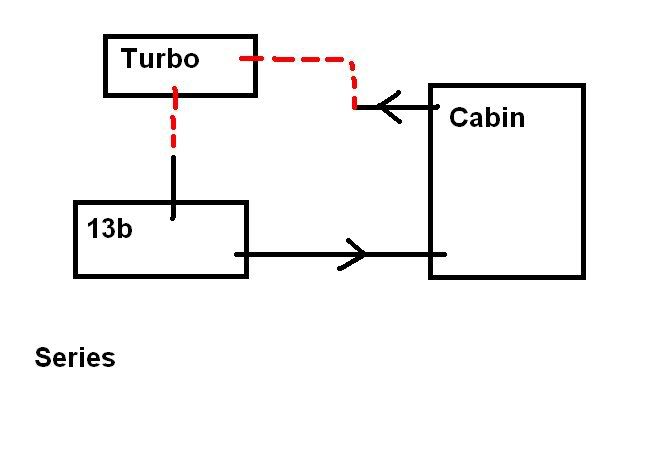

You'll also need to figure out how to work out the cooling to the turbo. You can do it one of two ways:

There are kits that can easily do this for you. So shop are around or figure out how you want to do it. But to make it easier do it the way as the first picture shows. The second one will not work.... So don't do it.

Linear Mode

Linear Mode