|

|||||||

| Show your rotary car build up. Show off your Rotary Car build! |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| Show your rotary car build up. Show off your Rotary Car build! |

|

|

|

Thread Tools | Display Modes |

|

|

#91 | |

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

Quote:

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group |

|

|

|

|

|

|

#92 |

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

Figured I'd get back and shoot some pictures.

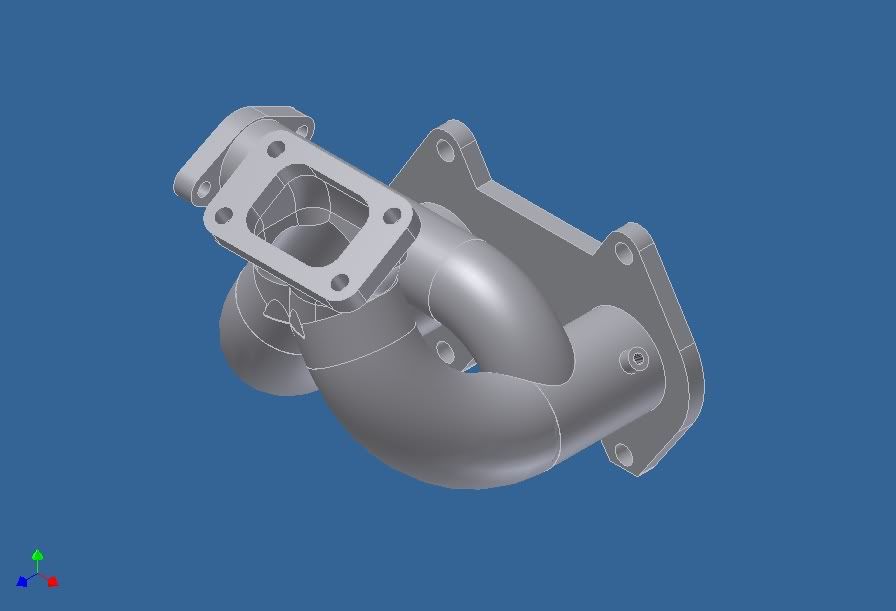

Here's a mock up of the turbo manifold I'll be making. It's not pretty, and it's not what I originally thought of how I would route the pipes. But after talking it over with a person more familiar with turbo modifications and finite space, he recommended this path for the turbo. There's a few benefits with doing it this way. It provides an easy access to the turbo, better oil drainage, and not to mention easier routing of all the lines. There is even ability to theoretically move up to a bigger turbo if I ever so desire (though a T60-1 is plenty big right now, especially for an NA engine with a large street port). This allows the 6PI to remain intact and still allows the easy access and manipulation of the turbo. The plan is to make this out of mild schedule 40 weld "L's" and be able to mount the turbo and access the bolts. The only down side to this setup is that it places the turbo fairly close to the brake line of the passenger front brakes. I do plan on protecting the lines before I do a wire/line tuck on the engine bay by either a heat deflector, protective wire wrap, or wrapping the brake line with some exhaust wrap (other possibilities may include a turbine blanket and wrapping the down pipe--though I'd prefer not to wrap the down pipe supplying me with the biggest temperature differential possible).

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group |

|

|

|

|

|

#93 |

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

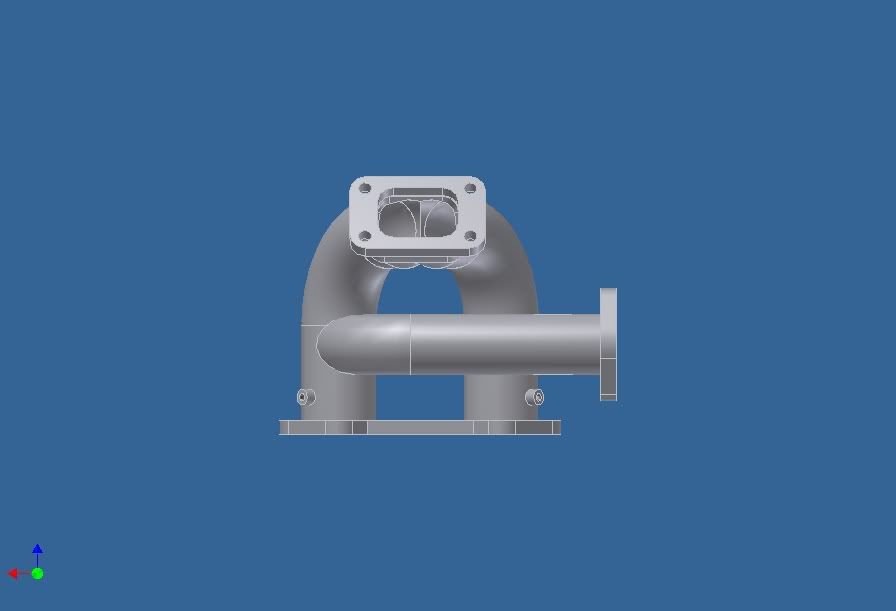

Here's a digital mock up. It's not super accurate, but accurate enough for the what it needs:

Didn't put in the turbo flange, but used the pipe run as best as I could. I don't think the up shot to the turbo will actually be as pig pictured there. Maybe two inches shorter.

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group |

|

|

|

|

|

#94 |

|

RCC Addict

Join Date: Feb 2008

Location: VA

Posts: 1,812

Rep Power: 19  |

You can also move the brake lines. They are cheap enough to make new ones if needed.

Also, I'm sure you've thought of it, but anticipate bracing those runners together... |

|

|

|

|

|

#95 | ||

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

Quote:

Quote:

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group |

||

|

|

|

|

|

#96 |

|

RCC Addict

Join Date: Feb 2008

Location: VA

Posts: 1,812

Rep Power: 19  |

Yea, schedule 40 is good, but the more weight you hang out over those bends over time will start to show signs of giving out...

Cant wait to see it when its done though... |

|

|

|

|

|

#97 | |

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

Quote:

Today was a stainless steel line day. I was able to pick up the -10AN for the oil cooler and with some help get them all connected. I took some pictures so check 'em out. Around this same time I realized that my fuel lines are not -8AN but -6AN talk about bad luck. Hopefully Todd hasn't already welded the -8 bungs to the fuel rails, but if he did I don't think it will be too much trouble to just put on an adapter for -6. We'll see though. But here are some pictures: When I dropped in the engine:  Notice the oil return flange. It's going to be a fun day when I actually can finally hook that up.  The turbo with the V-Band adapter mounted to it with the V-Band flange waiting for welding.  Prepping for figuring the turbo. My original intent was to mount the turbo very close to the stock location and just keep it as straight as possible. Didn't work out as you can see from the previous post.  Oil Cooler Lines. That's a 120 on the top, a 90 on the side. -10AN line. Not bad for $70.   Here's the beginning of my parallel fuel system. Should be feeding some 1200 cc/min and some 720 cc/min (I think, I'll have to double check the flow rates on the injectors). Should be enough fuel for my project. Anyone want to guess how much Horse power I'll make once I finally break the engine in and get it tuned?  Backside of the engine. Simple 90 and shoots forward. It's actually a much cleaner install than the stock lines and I'm surprised I didn't do this sooner.  Here's the oil cooler mounted and placed a few inches forward of the original position. If you look closely I cut out a portion of the angle iron to allow an additional inch of breathing room to the cooler.  A better angle of the new lower oil cooler line.

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group |

|

|

|

|

|

|

#98 |

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

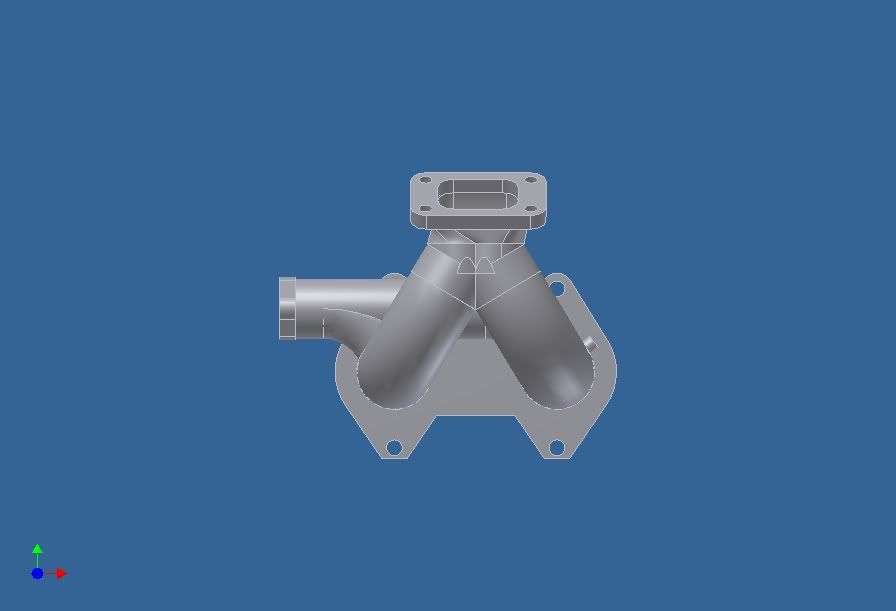

Well, now that I have the components to build the new manifold I went ahead and made it slightly more accurate. Honestly, I'm quite happy with how it turned out except for the transition component. Never mind that. But any suggestions on the manifold design thus far?

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group |

|

|

|

|

|

#99 |

|

crash auto?fix auto

Join Date: Feb 2008

Posts: 816

Rep Power: 18  |

Looks very similar to the A-spec FC manifold. Personally, I'd locate the wastegate runners closer to the tubrine. Looks decent though. How large of primaries are you going to run? They look pretty beefy in the renderings.

|

|

|

|

|

|

#100 |

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

Schedule 40 all the way around. 2in diameter on the primary runners, 1.5 in on the wastegate side. Can't really move them up since they'd start interfering with the 6PI actuators and down pipe. I did that rendering as accurately as possible. I'm re-thinking the transition piece however between the runners and the turbine inlet flange. I thought of a much easier and nicer looking transition to do it. may even prove to be more compact.

Something I'm still trying to figure out is how to do a stress analysis on the manifold assembly to see if I'll need to incorporate bracing in it.

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group |

|

|

|

|

|

#101 |

|

business as usual

Join Date: Apr 2008

Location: Emerald City

Posts: 154

Rep Power: 0  |

wow Have fun with yore project.

I just saw the list of parts hah Good luck.

__________________

Bitch |

|

|

|

|

|

#102 |

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

Post number 1? lol, there was sooo much more to the planning than that page. I'd have to dig it up again, but I think I had 1 work book with different spreadsheets specific to that portion of the build ie: oil, cooling, induction, exhaust, etc.

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group |

|

|

|

|

|

#103 |

|

crash auto?fix auto

Join Date: Feb 2008

Posts: 816

Rep Power: 18  |

I would run a little smaller primaries personally, something in the 1.75" flavour. 2" is pretty large, but it shouldn't hurt that much.

As far as interfering with your actuators, without really holding it up I'd have to go by what you're saying, but I really think you'd benefit in the boost control department from locating them closer to the turbine. Even if the height from the primaries didn't change, but you just rotated the runners 90* to face the primaries where they enter the turbine, you may be able to make them fit. I wouldn't think you'll need much bracing, that manifold is pretty short, and with some heavy wall stainless it will be pretty damn stout. |

|

|

|

|

|

#104 | |||

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

Quote:

Quote:

Quote:

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group |

|||

|

|

|

|

|

#105 |

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

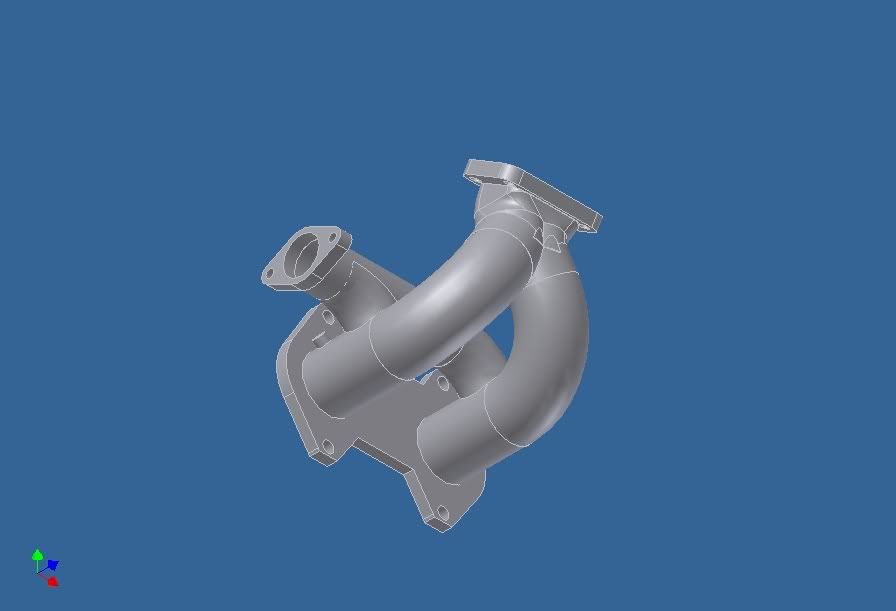

Finished welding up the primaries just prior to the collector today. I heart my friends TIG. I also started the wastegate runner. Trying to cut a 90* to fit onto a pipe mid-way through is quite difficult. I still have a few cuts to make before I hit it with a die-grinder. I also well need to drill holes and hit the wastegate runner with a die-grinder once I finalize the position of the exits. There really isn't any room at all to run the wastegate runner just below the collector as it does interfere a lot with the actuators, and there's no room to mount them on the outside of the bend near the collector as it will hit the strut tower and/or the frame. The only other option would be to mount the wastegate runner on the underside of the manifold, and there's really no point to that especially with how compact the manifold already is.

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|