|

|||||||

| Show your rotary car build up. Show off your Rotary Car build! |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| Show your rotary car build up. Show off your Rotary Car build! |

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

IT'S ALIVE!

Join Date: Dec 2009

Location: Richmond, VA

Posts: 811

Rep Power: 16  |

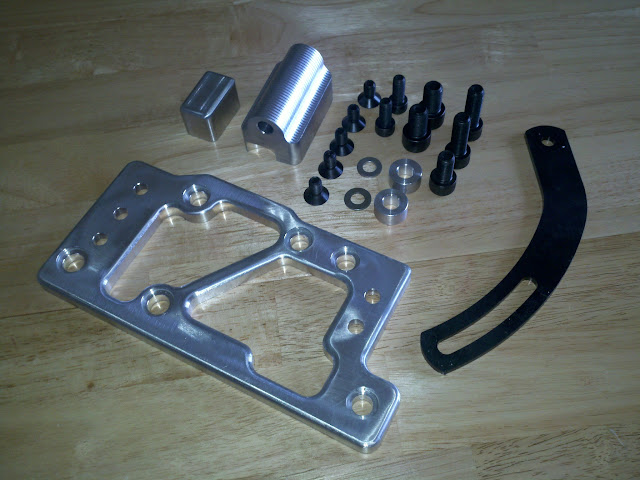

I was looking into alternator relocation kits to solve my interference issues last weel. I ended up going with the Xtreme Rotaries alternator relocation kit. I received this exactly one week after I placed the order. Not bad for shipping from Australia to Ohio. Here it is all unpackaged:

I'm pleased with the quality of the kit. 100% milled and polished aluminum and all bolt holes are counterbored/countersunk. I went with this kit due to the OEM-style tensioning system. All the other kits I saw used heim joints. In hindsight I could have made somehting like this myself but it wouldn't have been aluminum and it wouldn't be as nice. Installation was straightforward and I think I had more difficulty removing the studs from the front cover and front iron than setting up the alternator. Installed in the car:  It looks tight between the engine and the frame rail but even at both extremes of the tensioning range there is clearance. The only issue I ran into was with the tension arm. With the alternator installed the tension arm is about .25" away from the alternator mounting point. The stock tension arm has a couple bends in it where the arm included with the kit does not. This was easily fixed with a few washers. The only concern I have is how close the alternator is to the wiring harness and if that is going to cause interference issues with the CAS wires. Here's a couple shots of the intake setup on the car. I've got all the fittings in place and I'm ready to finish the fuel lines. You can also see the new fuel pressure gauge in this picture.  I think I mentioned the tight clearance between the TPS sensor and the water temperature sensor. This last picture shows just how close that is. I think I can still squeeze the TPS pigtail in there but if I absolutely have to I can relocate the water temperature sensor to somewhere else on the water pump housing.  Where are some other locations for a good water temperature sensor signal? This is for the Haltech so I want it to be a representative of the water temperature in the engine as possible. |

|

|

|

|

#2 |

|

Fired up!

Join Date: Aug 2011

Location: Queens, NY

Posts: 14

Rep Power: 0  |

Use the location the stock computer (once) used. Where you have it should work as long as it doesn't interfere with the thermostat.

|

|

|

|

|

#3 |

|

IT'S ALIVE!

Join Date: Dec 2009

Location: Richmond, VA

Posts: 811

Rep Power: 16  |

That's where I have it now - in the thermostat housing. It's the sensor in the foreground. The second sensor is for an independent water temperature gauge. The problem I have is my TPS connector is pointing straight at it so clearance is going to be tight.

|

|

|

|

|

#4 |

|

Lifetime Rotorhead

Join Date: Apr 2010

Location: Elkton, MD

Posts: 874

Rep Power: 16  |

Just a thought - is it possible to install the TPS clocked so the connector is 180 degrees off from where it's pointed now? You'll probably need to rewire the TPS connector too, to ensure mechanical WOT position corresponds to what the TPS needs to output electrically.

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|