|

|||||||

| Show your rotary car build up. Show off your Rotary Car build! |

|

|

Thread Tools | Display Modes |

|

|||||||

| Show your rotary car build up. Show off your Rotary Car build! |

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Get off my lawn!!!

Join Date: Jun 2011

Location: At a USO near you!

Posts: 715

Rep Power: 15  |

Fenda's uber garage Engine Build

Howdy guys!

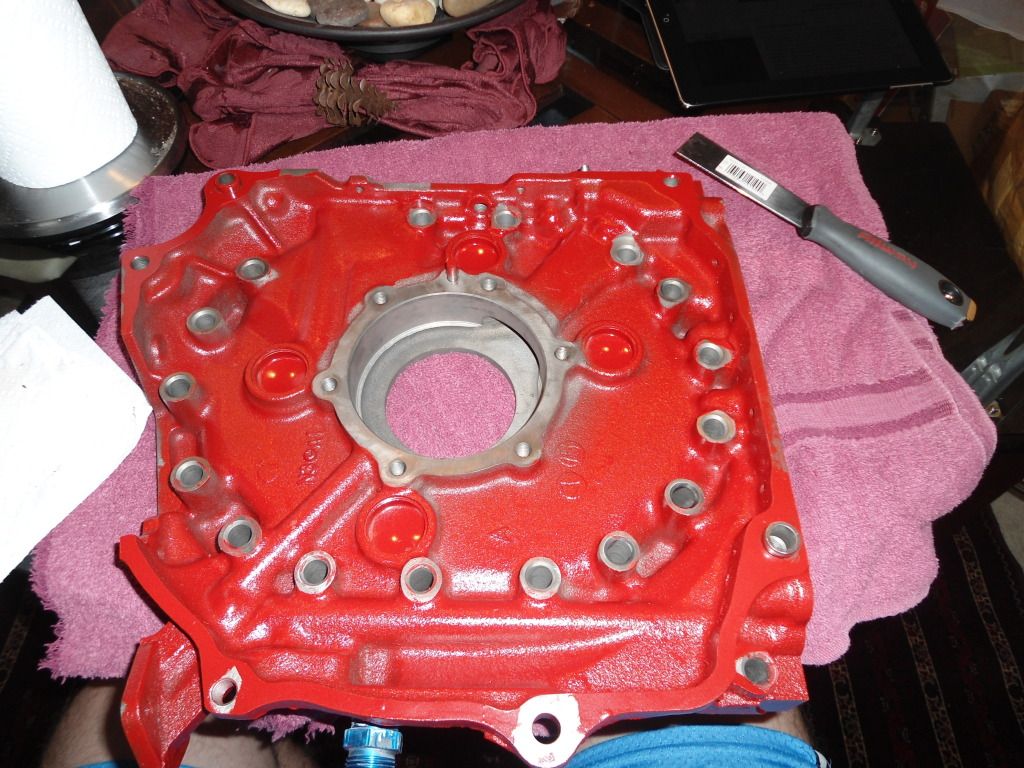

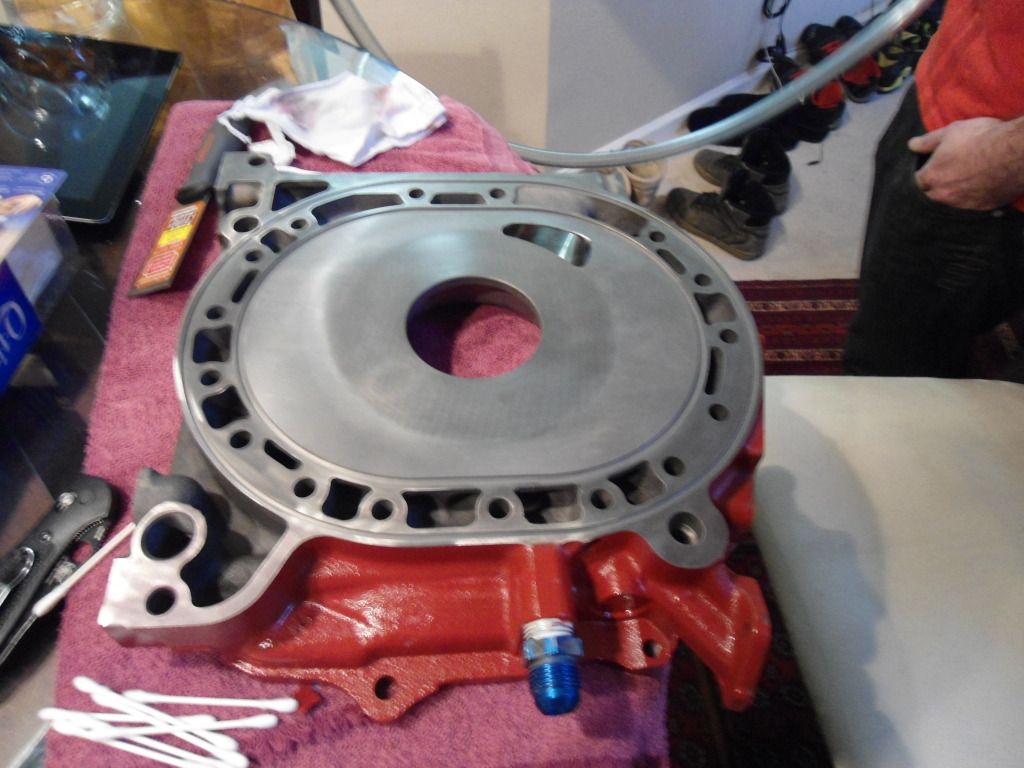

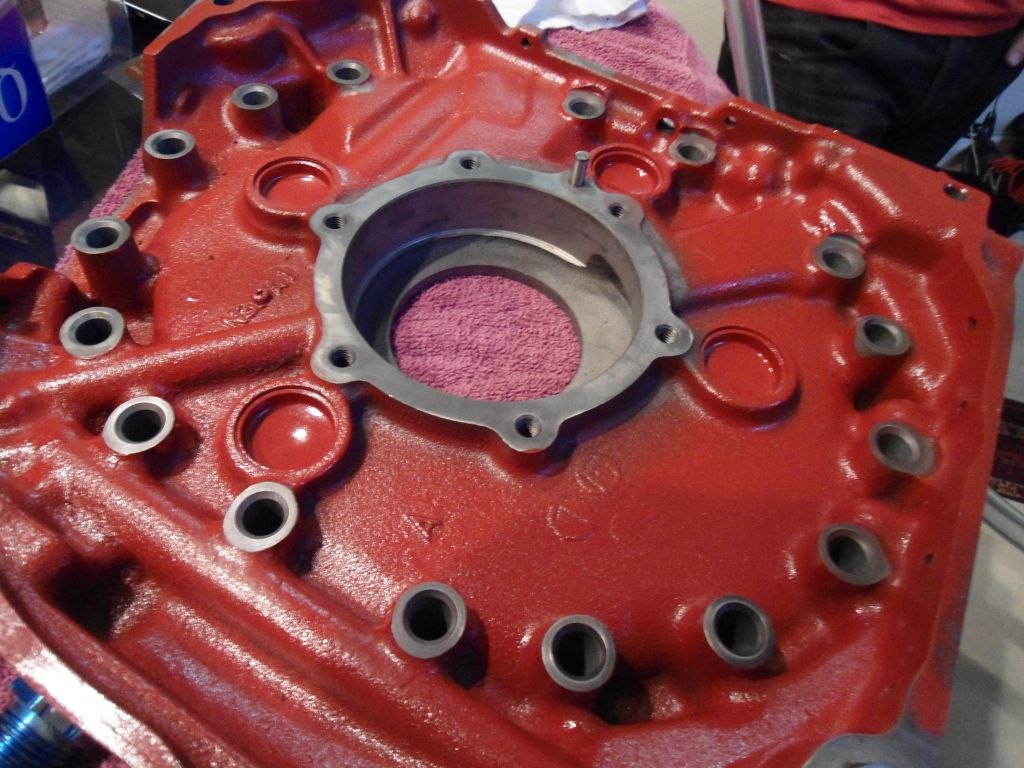

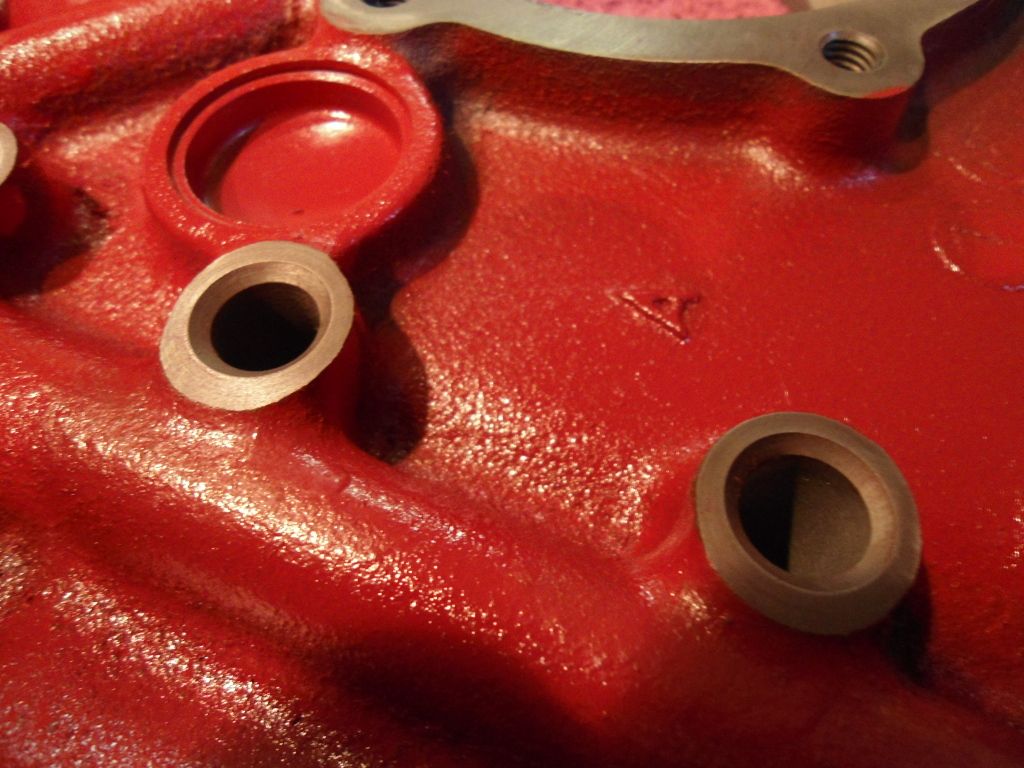

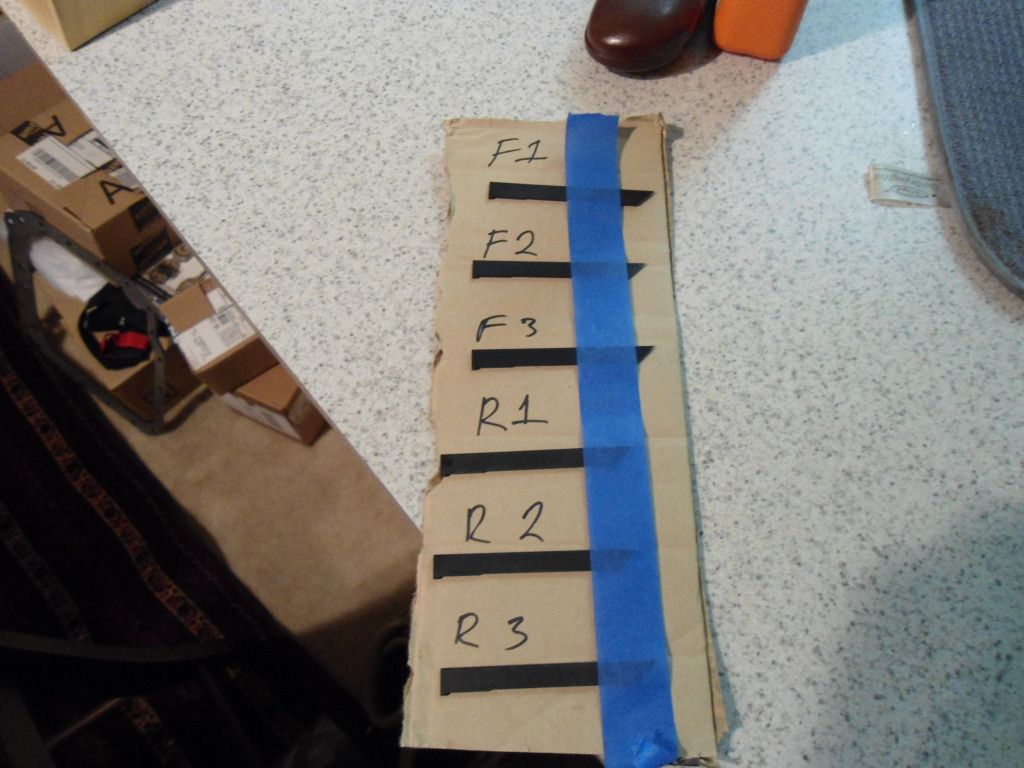

So this is my first ever "build" thread, both on here and on the 7 club. Over the past six years I've had a LOT of work done on my car, but I've never really taken an active hand in the work so I never felt right making a build thread since I didn't actually "build" it myself. Well... After multiple rebuilds being done by a "reputable" specialist shop that all failed within a few thousand miles I said fuck it, and decided to take my engines fate into my own hands. I enlisted the help of my friends who know much more about engineering and mechanics than I myself do, and I had work done and parts made by some top notch shops and fabricators in our industry. My own role in this engine build was minimal, however it was an incredible learning experience and I can't wait to do it again (though hopefully not TOO soon, lol). I've got to give credit where credit is due though: I started fresh with a new motor from Ray Crowe. Ray is THE man to speak to if you're looking for OEM parts in America, he owns a 3-rotor FD himself and works in the parts department of Malloy Mazda/Hyundai. Seriously, if you need something call Ray! His work number is: (703) 490-8170 Le Virgin Motor:  Chip Ursu, of Chips Motorworks (http://www.chipsmotorsports.com/) did an AWESOME job on my rotors. I picked up a set of S4 N/A rotors for my engine and had them sent to Chip for lightening, balancing, and clearancing. Chip didn't just make me something functional, he took some old rotors and returned me a work of art! Seriously, when I saw my rotors I was tempted to call the whole rebuild off... I wanted to mount my rotors up on the wall, lol. I seriously can't say enough good things about Chip and his outstanding service!!! Said Rotors: So sex...  We broke down the motor that I had bought from Malloy and, while the S4 rotors were being worked on by Chip, my housings and irons were ported by Speed1 in Allentown, PA. Chris at Speed1 did a badass job of streetporting my motor. Again, my experience with Speed1 was probably one of the best I've had with a tuning shop during the tenure of my FD ownership, both in America and while living in the UK. I *will* be taking my car to Speed1 from now on for tuning and work I can't/won't do myself. I picked up my apex seals from Adam at REC (www.rx7specialties.com) upon the advice that his black seals are essentially the RA SuperSeals, except that his won't gouge the shit out of your housings! Elliot, from www.turblown.net provided me with a stud kit that will significantly help the life and reliability of my engine by allowing for more consistent tension without worrying about the stock ones giving false readings. These studs help alleviate potential problems that could be experienced while using the stock tension bolts in higher HP applications. The best part is that his stud kit doesn't require (expensive) machining to your irons and housings. David Garfinkle is the freaking man!! I contacted him about his oil pan braces and he agreed to make another batch of them for me if I could help spread the word to other owners in the community. When I received his Oil Pan Brace I, like many owners before me, was incredibly impressed by the high standard of his workmanship. Needless to say, I feel sorry for anybody who doesn't have his brace and who missed out on this production run, since it seems they only come about once every year or three now. Aaron at FFE (http://fullfunctioneng.com/) did an awesome job about supplying me with ID injectors and primary/secondary fuel rails. I'm not really sure where Full Function finds the time to R&D, and produce, the products they turn out... but from my experiences I'd say that it would be VERY difficult to find any company that can rival them, regardless of their size and budget. These guys are absolutely the REAL deal  After a quick phone call, and a nominal fee, the guys at Goopy Performance (http://goopyperformance.com/) hooked me up with their rotor prep kit. Honestly, if you're going to be doing any rebuilds on your own as either a shop or an individual than you should REALLY invest in something like this. In general, having the right tools for a job make the job better. When it comes to building an engine I feel it's safe to say that if you DON'T have the right tools for the job than you are doing something wrong... Goopy definitely provides the right tools  As far as the actual knowledge and elbow grease that went into this build... Brian, aka TitaniumTT, has been a fucking godsend. He took his weekend off to drive the 4+ hours from Speed1 down to my apartment in Alexandria for the build. Mike, aka RXtacy, came over to lend his considerable skill and training in Mechanical Engineering to the endeavor as well. Seriously, Brian and Mike spend a good 6+ hours measuring, and rechecking, the clearances to build my rotors to absolute perfection. Old man Bawbers, aka BrewerBob, came over with his wife on Saturday and lent his sarcastic wit, badass brewing skills, and cooking prowess to make the evening run smoothly with laughs, delish grilling, and top-notch home brews felt all around. My buddy Vlad, aka Max_Spd, came by with his buddy Sy (a new FD owner) on Sunday to help with actually building the keg. With this being my first hands-on engine build I was surprised how much prep work was actually required, if you want to do it right. As far as the build itself goes, the tolerances were kept tight (like tiger!) and everything that wasn't specifically mentioned as aftermarket or special was 100% OEM and brand new from Ray Crowe. I'm sure you guys are tired of reading though, and want to see pictures  Saturday My work during the week (and Hurrican Sandy) started by cleaning, and then painting, the irons. While Brian and Mike were clearancing the Rotors on Saturday I cleaned up the irons of all the paint that oversprayed or dripped where it wasn't supposed to. Rear Iron, Pre-completion:   And here is the rear iron, ready to go:    Mike getting the side seal grooves ready:  Brian checking up on his:  Getting ready to check clearances on an apex seal slot:  Break time!!! Rotors were set where they rested, and I made the (first) hookah of the night. I learned how to make a proper hookah while living in Bahrain, I was taught by the Egyptian coal guys in Isis Cafe, in Manama.   That hookah lasted for a good hour or two before we finally lost interest and focused on making the rotors, and prepping the irons, again. And another look at those rotors, because SEX!!!  Mike shortening one of the side seals to fit the clearances that we ran for my engine. I'm dead serious when I say that Mike and Brian busted their asses getting these rotors ready. I owe a serious debt of gratitude to them for putting their time and knowledge towards helping me out!!      All the clearances measured, and the seals being assigned their respective spots on the rotor.    Greased up and ready for insertion baby    Fast forward to Sunday, we moved down to my garage and began assembling the keg. (My next post will have the work done on Sunday, as it stands right now it's 11:30pm on Sunday night and I am POOPED!!!)

__________________

'94 Touring - Cursed '96 NA Miata '14 Mazda3 Hatch '14 Aprilia RSV4 R Last edited by Fendamonky; 01-08-2013 at 08:57 PM. |

|

|

|

| Bookmarks |

|

|