|

|||||||

| RX-7 3rd Gen Specific (1993-2002) RX-7 1993-2002 Discussion including performance modifications and Technical Support Sections. |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| RX-7 3rd Gen Specific (1993-2002) RX-7 1993-2002 Discussion including performance modifications and Technical Support Sections. |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Rotary Fanatic

Join Date: Mar 2008

Location: Brenham, TX

Posts: 335

Rep Power: 18  |

My mechanical preturbo water injection

I did a writeup about 9 months ago on the "other" forum, I've decided to include the information over here to hopefully get more exposure/interaction on this site. Here are the main points I was looking for when I first decided to add the water injection. So taken from my first post on 12-15-08....

"1) The system design I'm using is mechanical and should have a lower chance of failing 2) Water is free/easily attainable 3) My car is mainly a street car and I'm just looking for a bit more boost with the added reliability of AUX injection 4) I'm cheap and like to do things myself" When I first decided to add the water I was at 15psi on a t61, my plan was to run 200-300cc of water @ 18 psi or so. I'm now running a t70 @ 23 psi daily and about 600cc of water. All on 93 premium pump fuel. The system uses no pumps, controllers or other electronics. The only electrical components are a solenoid, and a boost switch similar to a hobbs. It works by using boost pressure from the turbo to pressurize a sealed water tank, this forces the water through the line to the atomizing water nozzle. The nozzle has both a water and an air port to atomize the water very finely. The air port receives boost pressure from the turbo. Located before the atomizing nozzle is a solenoid which is activated at a preset boost pressure by the hobbs style switch. The water is fed directly into the turbo inlet. The key is to have the water fully atomized before it enters the engine. This prevents any compressor blade erosion from occurring. The benefits to preturbo injection, beyond the benefits of aux injection in general are. 1)Water is better atomized, allowing easier combustion & faster heat absorption 2)Lower Intake temperatures 3)It shifts the compressor map giving the turbo more efficiency at high boost levels. (much like the turbo is physically larger) My system has gone through a few alterations in the past 9 or so months, and I'll try to cover each of the phases in different posts to keep it somewhat separate. The next post will go into details of the parts used, along with some pictures. Stay tuned.

__________________

500+ HP thanks to:  Fast reacting IAT sensor thread! Mechanical Pre-turbo Water Injection Thread Dual Stock fuel pumps Thread T2 differential swap! |

|

|

|

|

|

#2 |

|

Rotary Fanatic

Join Date: Mar 2008

Location: Macungie, PA

Posts: 163

Rep Power: 18  |

This sounds like a great idea, i'm surprised nobody has thought of using the boost pressure to make a mechanical injection system. I too prefer mechanical systems as they are much less likely to fail, i'm interested to hear more.

__________________

Proud owner of a base 1993 Montego Blue FD. PFC, RB single tip, Koyo Radiator, KDR rebuilt motor, polished OEM front strut bar, FEED replica sideskirts, OEM 99 spec rear spoiler, SuperPro Bushings Many thanks to Dave at KDR for sparking my rotor addiction. |

|

|

|

|

|

#3 |

|

Founder/Administrator/Internet Pitbull :)

Join Date: Jan 2008

Posts: 644

Rep Power: 10   |

Any pictures of the set up?

__________________

DGRR 2013 - Year of 13B www.DealsGapRotaryRally.com http://www.facebook.com/Herblenny |

|

|

|

|

|

#4 |

|

Rotary Fanatic

Join Date: Mar 2008

Location: Brenham, TX

Posts: 335

Rep Power: 18  |

Alright the parts I used are:

1)Atomizing nozzle from http://www.spray.com/cat70/f/F16.html part number is sue18, in stock form it flows 380cc at 20psi. I started with it like this and a few months later drilled it out to flow 500cc at 20 psi, and close to 600 cc at 23 psi.  2)I have a well built polypropylene tank from US plastics almost a gallon in size.  3)An adjustable pressure switch purchased from a aux injection website.  4)A spare nitrous solenoid to cut water flow. 5)Various hoses. Before ordering the poly tank I was concerned it wouldn't be able to hold the pressure, so I conducted a small test. The test involves an innocent mobile1 container, a tire valve, and an air compressor. I drilled a hole in the cap and threaded a tire valve into it. I slowly increased the pressure checking each time with a tire gauge how much pressure was in the container. I got to 15 psi and took a 5 minute break to prepare myself for a loud BOOM, and maybe a slight bit of pain, as the container was definitely Ballooning. Once I got my shit together, I went ahead and upped the pressure up to 23 psi. Amazingly it held, I stopped there figuring that was enough to satisfy my curiosity. While it's not the same as the container I purchased, the plastic is much thinner with the mobile1, therefore if the cheap Mobile 1 plastic container held, I feel confident the one I got will hold even better. (which after 9 months it has proven its worth) Here is a picture of the mobile1 container with 23 psi in it.  When I first hooked the water injection up, I used a clear poly irrigation hose. I wasn't sure how it would hold up against the heat, but no one in town had any silicone hose. I drilled and tapped the turbo for a hose barb fitting and ran a hose to the tank which was drilled and tapped on top and bottom. As it turned out the hose on the turbo didn't hold up, and I replaced it with a fuel injection hose. I also originally mounted the nozzle inside the air filter and had it pointed directly at the turbo. I had to weld a stainless steel bolt onto the back of the nozzle (see first pic below), drill a hole in the filter and bolt it to the filter. It worked extremely well like this, but I later decided to add a cold air intake to my turbo and had to remove the nozzle from the air filter and mount it to the side of the CAI. I'll post the pics of how it was hooked up originally, then post how it's hooked up now while explaining the reasons for changes. Pics of the system not installed, you can get an idea of the parts and basic system.

__________________

500+ HP thanks to:  Fast reacting IAT sensor thread! Mechanical Pre-turbo Water Injection Thread Dual Stock fuel pumps Thread T2 differential swap! |

|

|

|

|

|

#5 |

|

Rotary Fanatic

Join Date: Mar 2008

Location: Brenham, TX

Posts: 335

Rep Power: 18  |

Here is a video of the system being tested with an air compressor, you can see how fine the mist of water is. Click to play in photobucket. It's crappy quality but a cool lil video.

Here are some pics of when it was first installed. As you can see there is "T" on the top if the tank. The air came from the turbo, to the T, into one side of the nozzle and to the tank to pressurize it. I later removed the T because I found a 5 psi pressure drop in the tank with the T in place. The red hose goes to the pressure switch out of view.

__________________

500+ HP thanks to:  Fast reacting IAT sensor thread! Mechanical Pre-turbo Water Injection Thread Dual Stock fuel pumps Thread T2 differential swap! |

|

|

|

|

|

#6 |

|

Rotary Fanatic

Join Date: Mar 2008

Location: Brenham, TX

Posts: 335

Rep Power: 18  |

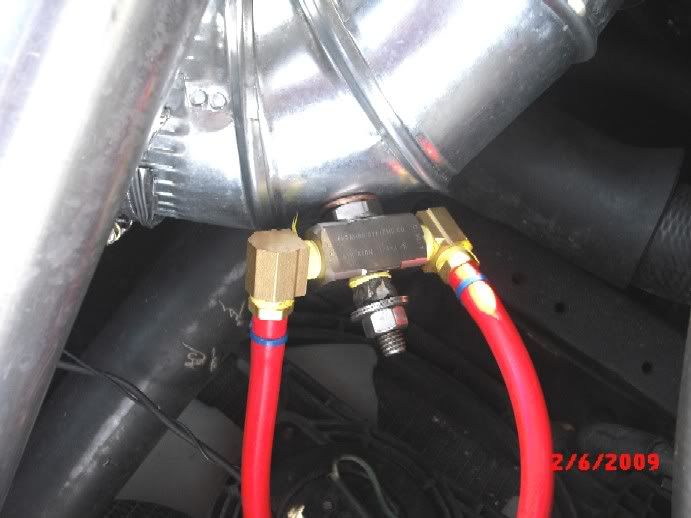

Here are some more recent pictures after making a few changes. As mentioned I removed the T so the turbo feeds directly into the tank, the air port on the atomizing nozzle is now tapped after the intercooler on the elbow. I tapped a new hole in the tank for the pressure switch. All the lines have been replaced with silicone, except the one on the turbo is still fuel injector line. I changed the injecting point from 3 psi to 8 psi which drastically lowered my water usage. I used to run out of water in under 20 mins of hard street driving, now it lasts several trips out. Drilled the nozzle to flow more water, I tested the new flow by setting my air compressor to 20 psi and allowing the water to flow into a measuring container for 1 minute.(500cc/min @20psi)I'm using a pretty trick fuel filter I picked up at Walmart for $10 dollars, it filters the water nicely and is serviceable for cleaning. In the last picture my tank has been moved more to the driver's side. I did this when I relocated my battery to the storage container. I plan on replacing the curved boost pipe with a straight pipe now that I have room. That's about it. Been working flawlessly for nearly a year at over 500 rwhp.

__________________

500+ HP thanks to:  Fast reacting IAT sensor thread! Mechanical Pre-turbo Water Injection Thread Dual Stock fuel pumps Thread T2 differential swap! Last edited by dudemaaan; 08-31-2009 at 06:34 PM. |

|

|

|

|

|

#7 |

|

RCC Contributor

Join Date: Mar 2008

Posts: 535

Rep Power: 18  |

My old turbo 1400cc kaw motorcycle has a SS water tank made into the sheetmetal work on the side of the rigid frame .The turbo pressurizes the tank and a pressure valve set at 8lbs lets the water go to a jet in the carb .The carb is suckthrough to a rayjay turbo. I built this bike in 1980 so the idea is not new.I still have the bike

|

|

|

|

|

|

#8 |

|

Rotary Fanatic

Join Date: Mar 2008

Location: Brenham, TX

Posts: 335

Rep Power: 18  |

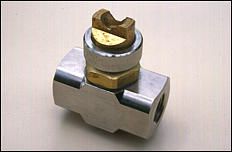

Where could I find a pressure valve like that? I would prefer to eliminate all electric components. Does the valve crack open at lower pressures and then fully open by 8 psi or just what?

__________________

500+ HP thanks to:  Fast reacting IAT sensor thread! Mechanical Pre-turbo Water Injection Thread Dual Stock fuel pumps Thread T2 differential swap! |

|

|

|

|

|

#9 |

|

RCC Contributor

Join Date: Mar 2008

Posts: 535

Rep Power: 18  |

Long ago I was a MR TURBO dealer and it was a part that they sold .It is tube shape and fit in the line,hose,from the tank to the carb .I will look for the old catalogs,or check out the part on the bike and see how it is made .

|

|

|

|

|

|

#10 |

|

RCC Contributor

Join Date: Mar 2008

Posts: 535

Rep Power: 18  |

Mr Turbo was a manufacture of turbo kits .The part in question had a screw to adjust the spring pressure . I will check on it for you .

|

|

|

|

|

|

#11 |

|

Rotary Fanatic

Join Date: Mar 2008

Location: Brenham, TX

Posts: 335

Rep Power: 18  |

Alright cool. That would be great.

__________________

500+ HP thanks to:  Fast reacting IAT sensor thread! Mechanical Pre-turbo Water Injection Thread Dual Stock fuel pumps Thread T2 differential swap! |

|

|

|

|

|

#12 |

|

Rotary Fanatic

Join Date: Mar 2008

Location: Brenham, TX

Posts: 335

Rep Power: 18  |

__________________

500+ HP thanks to:  Fast reacting IAT sensor thread! Mechanical Pre-turbo Water Injection Thread Dual Stock fuel pumps Thread T2 differential swap! |

|

|

|

|

|

#13 |

|

Rotary Fanatic

Join Date: Mar 2008

Location: Brenham, TX

Posts: 335

Rep Power: 18  |

__________________

500+ HP thanks to:  Fast reacting IAT sensor thread! Mechanical Pre-turbo Water Injection Thread Dual Stock fuel pumps Thread T2 differential swap! |

|

|

|

|

|

#14 |

|

Still Building my FD

Join Date: Jun 2009

Location: Pasco, WA

Posts: 255

Rep Power: 17  |

the check valve with the adjustable head pressure would be perfect for making your setup completely mechanical.

|

|

|

|

|

|

#15 |

|

Rotary Fanatic

Join Date: Mar 2008

Location: Brenham, TX

Posts: 335

Rep Power: 18  |

Both of them are adjustable. I ordered the second one cause it's under $10 with shipping. The first one is like $80. We'll see how it works.

__________________

500+ HP thanks to:  Fast reacting IAT sensor thread! Mechanical Pre-turbo Water Injection Thread Dual Stock fuel pumps Thread T2 differential swap! |

|

|

|

|

| Bookmarks |

|

|