|

|||||||

| Show your rotary car build up. Show off your Rotary Car build! |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| Show your rotary car build up. Show off your Rotary Car build! |

|

|

|

Thread Tools | Display Modes |

|

|

#376 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

|

|

|

|

|

|

#377 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

|

|

|

|

|

|

#378 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

First of all I'm very proud to annouce this link

http://www.build-threads.com/general...uilds-of-2013/ Back on topic. Builded some new benches to work on, and then started to assembly the dummy again to put back in the car for some measurements.    Tonight I was out on the highway and meet a friendly truckdriver from Czech Republic. He had brought a 20B flexplate from hIGGI on the Rx7Club-forum. Thanks alot for that hIGGi!  Also got some V-band-clamps today. Perfect size. Small and tight, just like we want them.

|

|

|

|

|

|

#379 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

V-band might have vacuum leaks.

__________________

'89 RX7 GTU, half-Bridge-port S4/S5 NA, E6K, Full RB exhaust, weekend warrior. '83 RX7, The "this might take awhile" project. '87 RX7 GXL, Rest In Pieces. '98 Subaru Impreza Outback-sport, rx7 rescue vehicle, down for repair. '94 Ford Ranger, daily. |

|

|

|

|

|

#380 |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 18  |

Nothing a recessed O'ring grove machined into the face with small O section O ring will not fix

Easy solution did very similar on multiple similar joins in a physics lab when I was machinist there

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration |

|

|

|

|

|

#381 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

Notice that this is just a test-housing. The port insert are in steel in this one just to get the shape.

When satisfied, its going to be aluminium with o-rings :-) |

|

|

|

|

|

#382 |

|

cxxxx|::::::::::::>

Join Date: Nov 2009

Posts: 315

Rep Power: 16  |

Tegheim seriously 1 of the best threads ever!

|

|

|

|

|

|

#383 |

|

Get off my lawn!!!

Join Date: Jun 2011

Location: At a USO near you!

Posts: 715

Rep Power: 15  |

I just read this whole thread from the beginning...all I can say is WOW!!! The thought and work going into this is incredible!

__________________

'94 Touring - Cursed '96 NA Miata '14 Mazda3 Hatch '14 Aprilia RSV4 R |

|

|

|

|

|

#384 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

Not much is happening at the moment.

I shortened my steering rack at last. Cut 220mm of an let 200mm be left.          Took some M24-nuts and machined out the threads. Then put them over my 4-link rods for adjustments later on. Just a little work with the TIG, and they are ready for some paint.  Are going with these 15.99mm solid dowels straight through the engine. Better off than the OEM.

|

|

|

|

|

|

#385 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

|

|

|

|

|

|

#386 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

|

|

|

|

|

|

#387 | |

|

⊙⊙

Join Date: Dec 2009

Location: Great Falls

Posts: 1,258

Rep Power: 17  |

__________________

Quote:

|

|

|

|

|

|

|

#388 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

Moment of truth, or point of no return for these housings...

The original "oil-nozzle" must be removed before milling or else my tool, or my housing will be broken.  Started with a M10-bolt and drilled a Ø4.2mm hole to allign the drill. Threaded M5, and pulled it out with some washers and a M5-bolt.    Machined a Ø63mm hole for the thread, and then removed all stuff the pointed out form the housing.   All done. Next step is the inserts!

|

|

|

|

|

|

#389 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

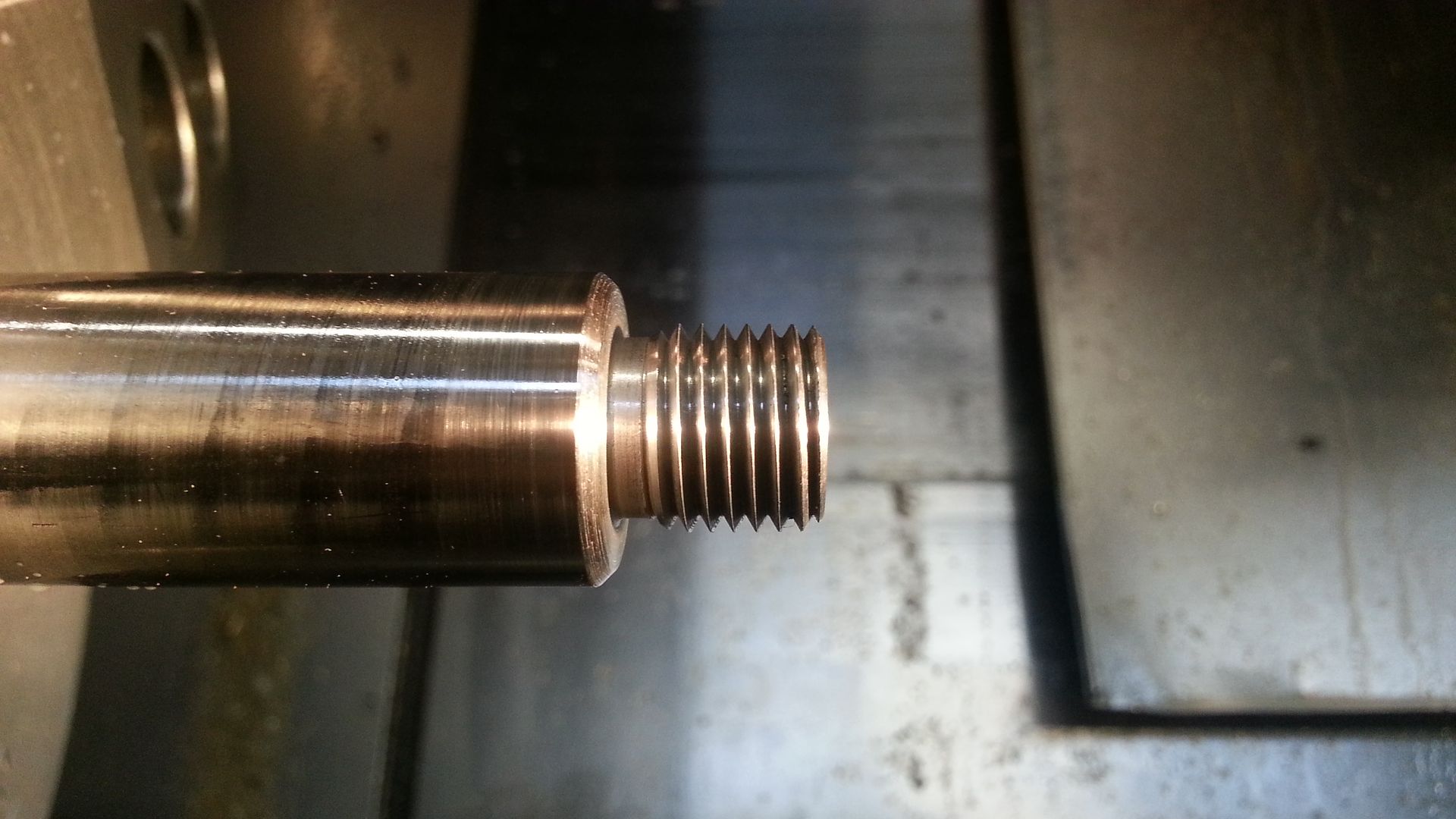

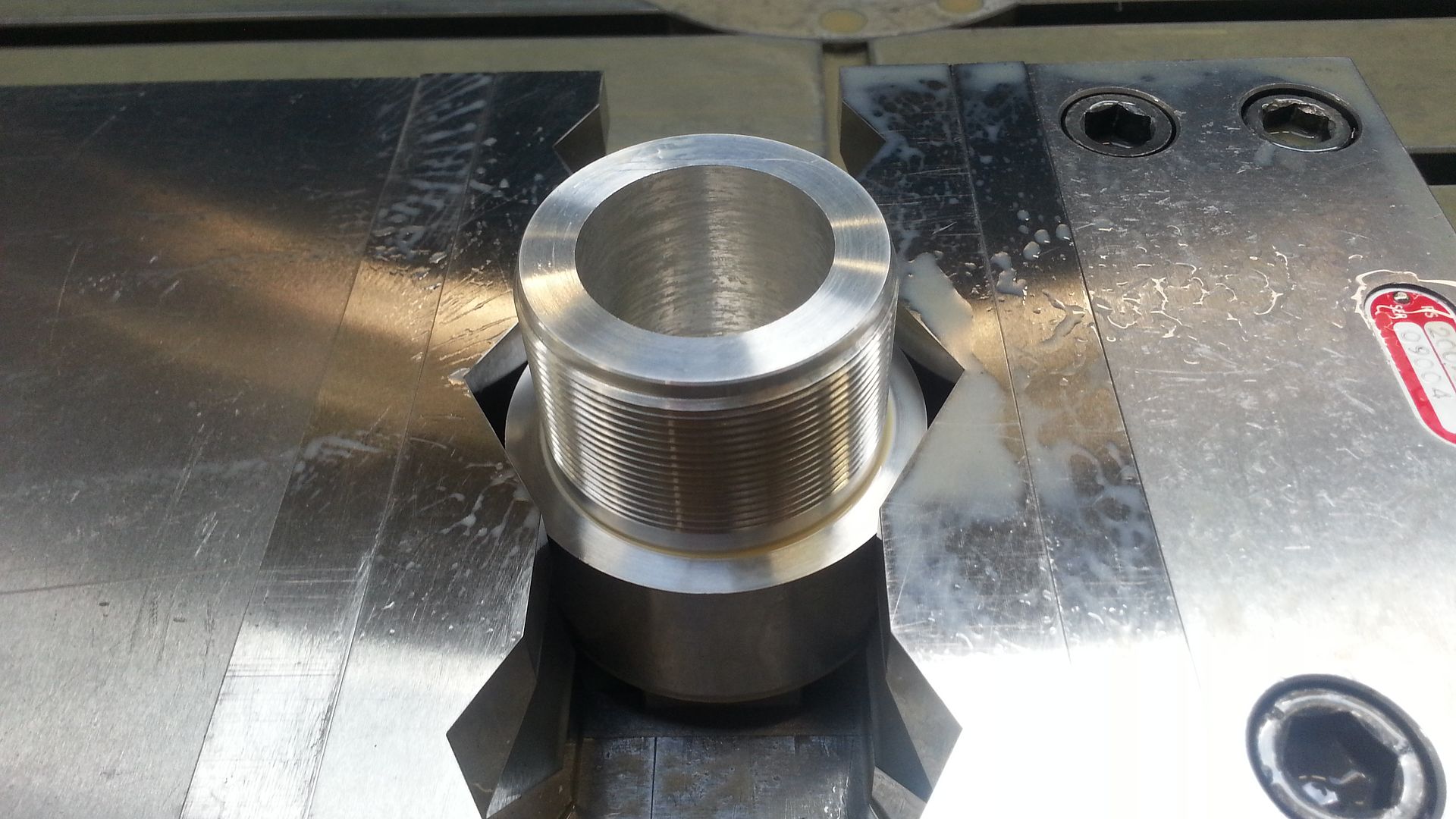

Yesterday I continued with my Peripheral-inserts.

Because they are threaded into the housings there is imported to get the D-shape in the right angle to align with the pre-machined D-shape in the housings. The D-shape closest to the housing are bigger than the round hole and the runners, so therefore I need to machine this with the inserts on the side. I could have done a round hole in the center, and port the sleeves by hand. But I'm really not a "handyman"  And CNC-port are in my opinion the coolest. And CNC-port are in my opinion the coolest.It worked out pretty well! I was really nervous when I mounted the first insert... I very satisfied. Next is to deside how to couple the inserts with the runners, and also how my runners will look like, size and lenght. Butterfly-throttles or slides.

|

|

|

|

|

|

#390 | |

|

⊙⊙

Join Date: Dec 2009

Location: Great Falls

Posts: 1,258

Rep Power: 17  |

Rotar Cave!

__________________

Quote:

|

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|