|

|||||||

| Rotary Tech - General Rotary Engine related tech section.. Tech section for general Rotary Engine... This includes, building 12As, 13Bs, 20Bs, Renesis, etc... |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| Rotary Tech - General Rotary Engine related tech section.. Tech section for general Rotary Engine... This includes, building 12As, 13Bs, 20Bs, Renesis, etc... |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

destroy, rebuild, repeat

Join Date: Feb 2008

Location: Charleston, SC

Posts: 395

Rep Power: 18  |

electronic wastegate

how come nobody makes an electronic wastegate? im not talking ebc, i mean an electrically operated wastegate. i think it would be very useful if you had an ems with a dedicated pwm map for it. you could run any boost you wanted at any rpm and load point, and not limited to a minimum of conventional wg spring. you could also use it as a safety device.. if your ems detected a failure, it could open the wg, preventing boost, not like a conventional wg that will boost spring pressure at a minimum

i would like to try keeping the wastegate fully open at low loads to decrease backpressure during cruising and see how that would get better mpg too

__________________

1993 RX-7 Touring MB, stockport 13B-REW, 9.4CR rotors, T04S 60-1/p-trim single turbo 1986 RX-7 Base project track beast |

|

|

|

|

|

#2 |

|

Rotary Masochist

Join Date: May 2008

Location: Floyds Knobs, IN

Posts: 494

Rep Power: 18  |

There is a thread on efi101 talking about this. In short, there really aren't components available to do what you're suggesting that will stand up to the heat very well.

The closest you'll get to what your suggesting, that is currently available, is a variable geometry hotside. That would actually have all the benefits of what you're suggesting as well as improved spool characteristics.

__________________

_______________________________________________ One stop Haltech, AEM, Syvecs shopping. Installation and tuning. http://www.lms-efi.com Free support. Drop us an email. chris@lms-efi.com 502-515-7482 Facebook @LMS-EFI |

|

|

|

|

|

#3 |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Heat + electronics = FAIL

On top of that, why even bother with PWM control? Current mechanical WG + EBC = PWM control. I'd rather go stepper motor control if you can get the electronics to hold up to the heat... -Ted |

|

|

|

|

|

#4 | |

|

Lifetime Rotorhead

Join Date: Apr 2010

Location: Elkton, MD

Posts: 874

Rep Power: 16  |

Quote:

As the OP suggested, a completely electronic WG control & actuation function would allow you to bypass the turbo on demand, like running in "N/A only" mode for economy. In a mechanical WG + EBC = PWM control setup, you still can can't limit boost below the WG spring tension. Of course your right foot can keep you out of boost just as effectively, but that's no fun. |

|

|

|

|

|

|

#5 |

|

Rotary Masochist

Join Date: May 2008

Location: Floyds Knobs, IN

Posts: 494

Rep Power: 18  |

There are already applications that run the wastegate without a spring. Compressed air is used on to hold the valve closed against manifold pressure. If you wanted to open the valve at low load, you could easily do it with a decent standalone, a 4-port solenoid, and a small air tank. I'd wager your gains would be miniscule at best.

__________________

_______________________________________________ One stop Haltech, AEM, Syvecs shopping. Installation and tuning. http://www.lms-efi.com Free support. Drop us an email. chris@lms-efi.com 502-515-7482 Facebook @LMS-EFI |

|

|

|

|

|

#6 |

|

The Newbie

Join Date: Jan 2012

Posts: 21

Rep Power: 0  |

The most reliable setup is and will always be a fully mechanical system. The engine management should provide bounds to the operation.

Over RPM Cutout: x rpm Over Boost Cutout: x boost Have a think about motoring in general until late 1990s. Brakes = mechanical with vacuum assistance Steering = mechanical with crank driven assistance Throttle = mechanical Gear selection = mechanical What happens when you are driving a drive by wire car, with an automatic gearbox and there is a control malfunction? Electronic Systems like this really need to be properly tested and qualified (costs $$$millions) |

|

|

|

|

|

#7 |

|

Rotary Fanatic

Join Date: Feb 2008

Location: Shelby Twp MI.

Posts: 315

Rep Power: 18  |

I came across a picture of a drag v8 set up that had wastegates with some type of electronic control/assist. I will try to find that pic again.

but it looks like they are out there, probably not main stream yet... |

|

|

|

|

|

#8 | |

|

Rotary Masochist

Join Date: May 2008

Location: Floyds Knobs, IN

Posts: 494

Rep Power: 18  |

Quote:

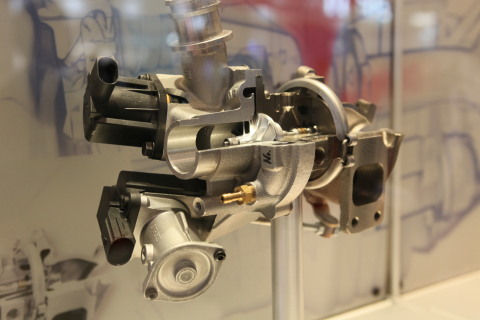

Did it look something like this? That's a valve position sensor in the pic.

__________________

_______________________________________________ One stop Haltech, AEM, Syvecs shopping. Installation and tuning. http://www.lms-efi.com Free support. Drop us an email. chris@lms-efi.com 502-515-7482 Facebook @LMS-EFI |

|

|

|

|

|

|

#9 |

|

Rotary Masochist

Join Date: May 2008

Location: Floyds Knobs, IN

Posts: 494

Rep Power: 18  |

Also, FWIW, what the OP is talking about does exist.

http://2009.tokyo-motorshow.com/en/g...rts-W/051.html

__________________

_______________________________________________ One stop Haltech, AEM, Syvecs shopping. Installation and tuning. http://www.lms-efi.com Free support. Drop us an email. chris@lms-efi.com 502-515-7482 Facebook @LMS-EFI |

|

|

|

|

|

#10 |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Is just the bottom one connect to the turbine side?

The top solenoid looks like it's connected to the compressor side, so that's more like an electronically controlled compressor bypass valve. I've seen wastegates used on the compressor side, but this can induce huge amounts of compressor surge upon opening. -Ted |

|

|

|

|

|

#12 | |

|

Rotary Masochist

Join Date: May 2008

Location: Floyds Knobs, IN

Posts: 494

Rep Power: 18  |

Quote:

Good question. Looks like you may be right. Looking at the pic, from the description that was given to me, I was thinking the valves were on the exhaust side. But they don't appear to be, now that you mention it. Their literature mentions lowered exhaust pressure, so one would assume their has to be some sort of exhaust bypass. Don't see it though. From Mahle's site: "MAHLE GmbHElectrical waste gate actuator Electrical waste gate actuator The electrical wastegate actuator improves engagement by avoiding the so-called turbo lag. In addition the fuel consumption is reduced because the exhaust gas counter pressure is kept as low as possible. Advantages include: Up to 4% lower fuel consumption. Lower CO2 emission. High closing forces, High regulation quality. High position and repeat accuracy. Compact and robust design. Can be diagnosed."

__________________

_______________________________________________ One stop Haltech, AEM, Syvecs shopping. Installation and tuning. http://www.lms-efi.com Free support. Drop us an email. chris@lms-efi.com 502-515-7482 Facebook @LMS-EFI |

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|