|

|

#151 | |

|

Rotary Non-conformist

Join Date: Mar 2011

Location: Speedway (Indianapolis)

Posts: 38

Rep Power: 0  |

Quote:

std egt for a race rotary are around 1600 to 2000 deg F piston race engine 1400 to 1700 deg F pending on tune and application there are coatings that can be aplyied to the rotor for high-temperature oxidation and corrosion if that would be a problem |

|

|

|

|

|

|

#152 | |||

|

IT'S ALIVE!

Join Date: Dec 2009

Location: Richmond, VA

Posts: 811

Rep Power: 16  |

Quote:

We actually use compressor bypass air to cool turbine components the "cooled" air is actually north of 1000F, typically. We actually use compressor bypass air to cool turbine components the "cooled" air is actually north of 1000F, typically.Quote:

Quote:

Sorry to get OT but this is a good discussion. |

|||

|

|

|

|

|

#153 |

|

Sigh.....

Join Date: Feb 2008

Location: Murfreesboro, TN

Posts: 2,377

Rep Power: 20  |

I support the cheapness. It's cutting weight and costs less than a used rotor. Win/win.

__________________

1986 Sport: 132k miles, 5A (Sapphire Blue Metallic), Tokico Blues, Racing Beat Springs, Custom LED tailights (only S4 LED tails in the world), SSR Mark II, Racing Beat exhaust, S5 black interior, Rotary Resurrection rebuild at 120k miles Community Service Manual RotorWiki "Imagination costs nothing; we could build square locomotives or fly to Mars" - Felix Wankel Yesterday is history, tomorrow is a mystery, but today is a gift. That is why it is called the "present." |

|

|

|

|

|

#154 |

|

Rotary Non-conformist

Join Date: Mar 2011

Location: Speedway (Indianapolis)

Posts: 38

Rep Power: 0  |

[QUOTE]Default

Quote: Originally Posted by rgould View Post That I would agree with that on a modern-day turbine components but you also have to remember that modern-day turbines are cooled only by extra air being forced through the insides of the blades so the actual metal temp on a modern-day turbine components is a lot higher than the actual metal temp of a rotor witch is cooled on each rotor face by an intake charge of air and fuel and the internal side of the rotor has engine oil cooling it there by making the rotor more like a piston than a turbine component ( the turbine components never see a cool down cycle once its up and running ) No need to explain to me; I design turbine stators (we call 'em nozzles) for a living We actually use compressor bypass air to cool turbine components the "cooled" air is actually north of 1000F, typically. Yes the rotary runs hotter than a pistion engine with its EGT temps But it is still a water and oil cooled engine witch still goverend bt some constancs Quote: Originally Posted by rgould View Post std egt for a race rotary are around 1600 to 2000 deg F piston race engine 1400 to 1700 deg F pending on tune and application That isn't as bad as I thought but still too high for Ti. From what I've seen 1000F is about the limit. In the turbine actual metal temperatures can get above 2000F, which is getting out of range for most traditional nickel-based alloys and then you've got to start getting into directionally solidified and single-crystal alloys with protective coatings... Quote: Originally Posted by rgould View Post there are coatings that can be aplyied to the rotor for high-temperature oxidation and corrosion if that would be a problem I'm familiar with your typical TBC's and environmental coatings on turbine components but not in compressors. In the aviation world compressor blades typically are bare Ti or have some kind of anti-abrasion coating. Sorry to get OT but this is a good discussion. Was not trying to o fend by explaining the turbin cooling. You never realy know the person background but it also lets outher people know what we are talking about I would say that the running temp of a rotor would be less than 500 deg F if it's that high. The Apex spring, side seai springs and corner butten springs would not be able to keep there strengh at temps higher than that. Another point would be that a rotor beinging hotter than that the oil on the inside would want to cristlize due to the heat. Also the rubber oil control seai would be more likely to fail as well. An alum piston melts at around 1200 deg F yet a race engine see EGT of 1400 to 1700 deg F and the piston does not melt if tuned correct thanks to the water in the block and the oil in the sump keeping operating temp in a range of 180 to 230 deg F for both water and oil. The same is true of the rotary yes the EGT is higher and the parts are hotter but they still operate in a range of 180 to 230 deg F for both water and oil. But it's good to have this discussion Last edited by rgould; 11-21-2011 at 05:43 PM. |

|

|

|

|

|

#155 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

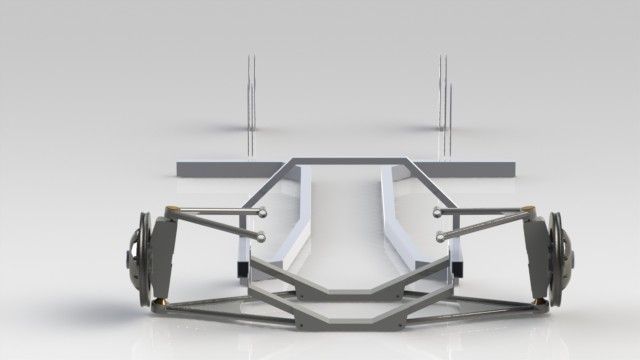

Everything goes according to plan, but everything has its time

Meanwhile, the graphic card goes hot in the computer. Is updating my drawings on the chassis and so on. And when inspiration is short, so make it a nice rendering, so you will be happy again

|

|

|

|

|

|

#156 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

|

|

|

|

|

|

#157 |

|

The Newbie

Join Date: Sep 2008

Location: orygun

Posts: 21

Rep Power: 0  |

Amazing project! Good luck!!

|

|

|

|

|

|

#158 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

|

|

|

|

|

|

#159 |

|

I have Ultra power in me.

Join Date: Sep 2011

Posts: 457

Rep Power: 15  |

1-4-2-3? firing order?

|

|

|

|

|

|

#160 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

1-3-2-4, maybe I done it wrong in the movie? :P

|

|

|

|

|

|

#161 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

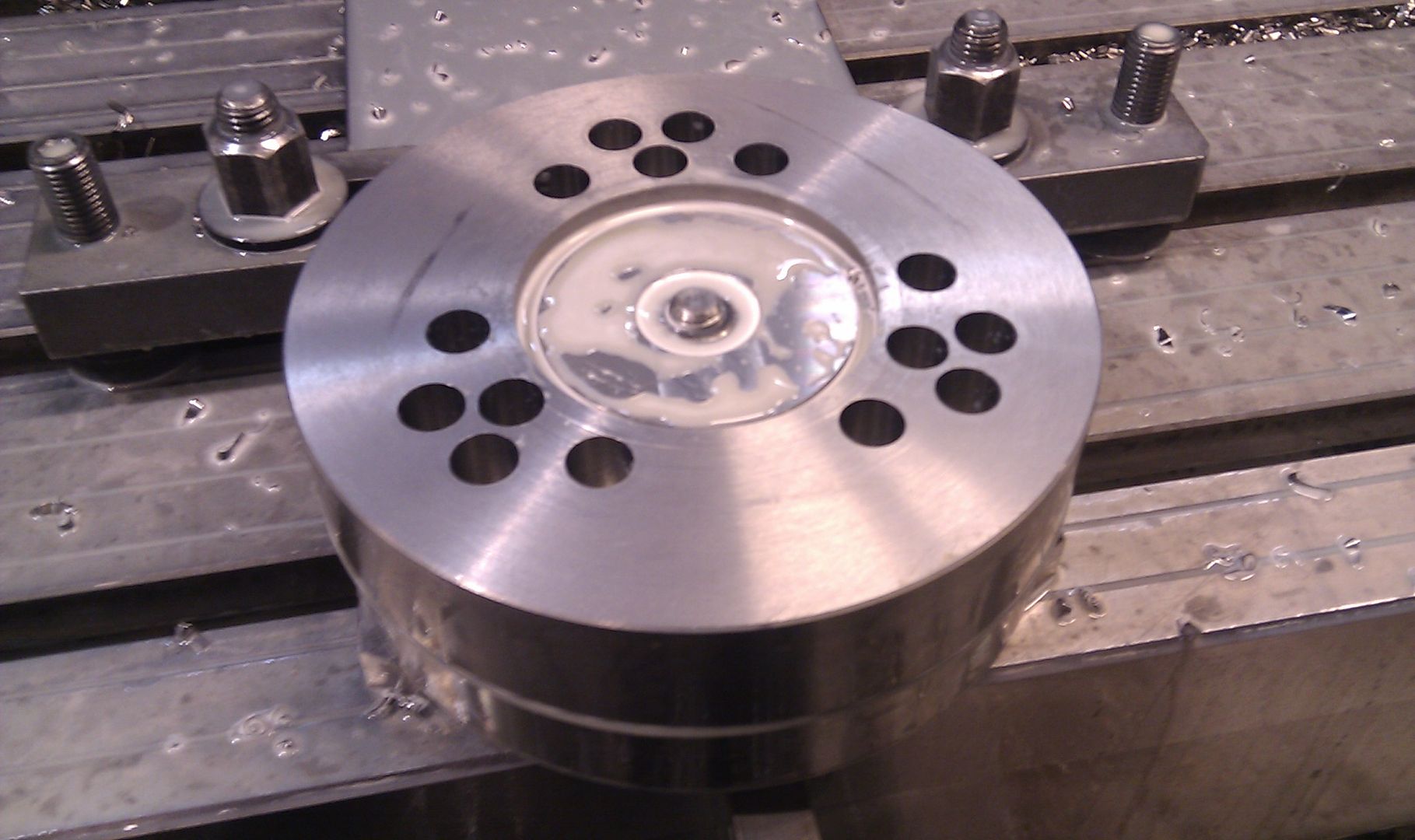

A good start on a looong weekend...

|

|

|

|

|

|

#162 |

|

Rotary Fanatic

Join Date: Oct 2008

Posts: 274

Rep Power: 18  |

^ wow!

|

|

|

|

|

|

#163 |

|

I have Ultra power in me.

Join Date: Sep 2011

Posts: 457

Rep Power: 15  |

I wish I had at least half of the tools and the know how to run them.

|

|

|

|

|

|

#164 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

3.45min

9.55min

|

|

|

|

|

|

#165 |

|

The Newbie

Join Date: Dec 2011

Posts: 1

Rep Power: 0  |

fantastic work you're doing Tegheim. thanks for the updates.

on the titanium front- if you were art 7stock you may have seen these    they are being made for a helicopter..... |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|