|

|||||||

| RX-7 2nd Gen Specific (1986-92) RX-7 1986-92 Discussion including performance modifications and technical support sections. |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| RX-7 2nd Gen Specific (1986-92) RX-7 1986-92 Discussion including performance modifications and technical support sections. |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

The Newbie

Join Date: Jul 2010

Posts: 14

Rep Power: 0  |

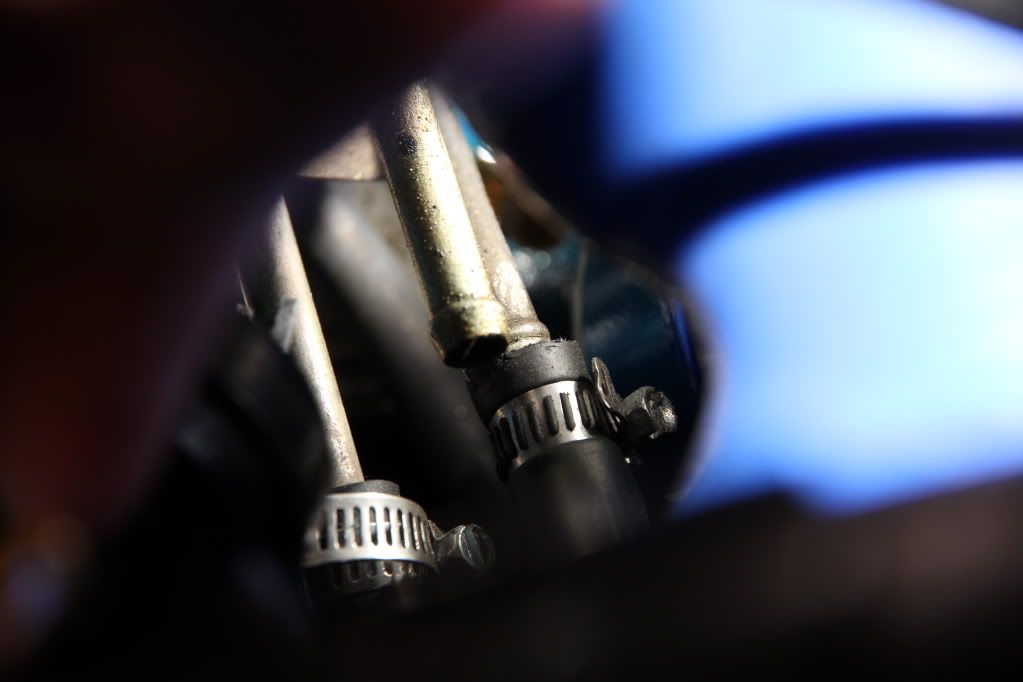

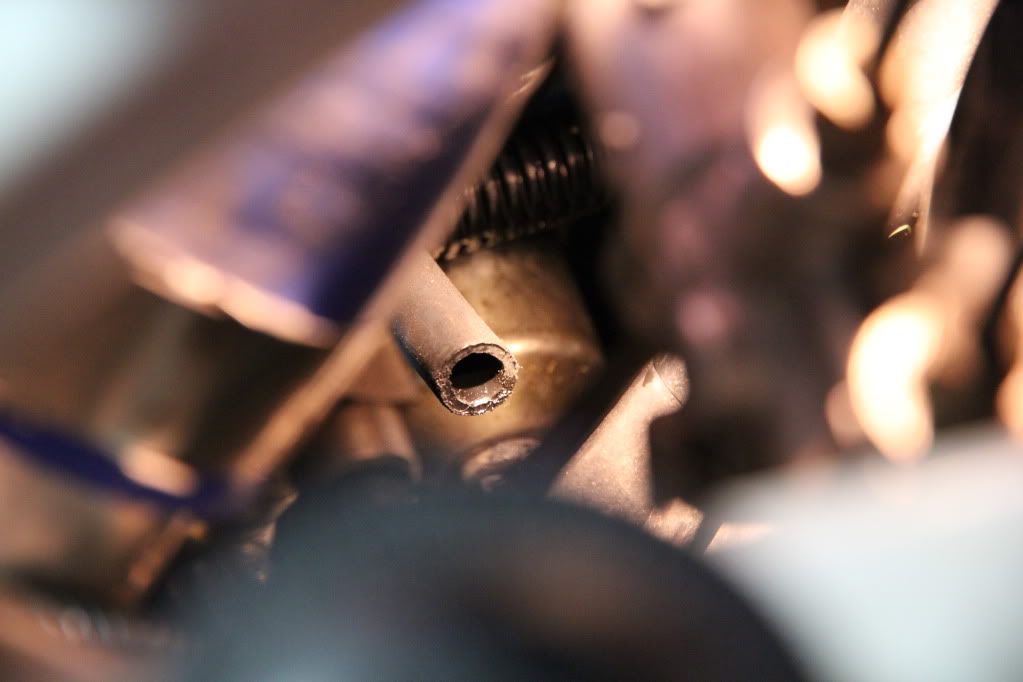

Fuel Leak

1987 RX-7 GXL

s5 turbo shortblock, trans, and turbo. s4 manifolds and accessories front mount intercooler I change my oil and start the car to make sure the oil isn't leaking from the newly installed filter and I see clear drops coming from near the oil filter. I stick my hand in there, smell my fingers, and its fuel. I have a hard time smelling gasoline after owning this RX-7 for so long so I needed to get it close to my nose. I look and theres a couple lines that I think are fuel. I figured one of the radiator style clamps was leaking, so I went to take them off and retighten them, when I found a third nipple that was unoccupied. I look around and sure enough theres a hose that isn't going anywhere. I turn the car on but then I didn't see the drops of fuel again, but I doubt the one radiator clamp I retightened fixed the issue. The drops aren't coming out of the hose going to nowhere or the unoccupied nipple. I just got the car back maybe 3k miles ago from having the engine rebuilt and all the work was done by the shop. The only issue that I know of is that when I got the car back, there was a line going from the charcoal canister (pictured) to the other side of the engine bay and a vacuum hose was dangling there by the oil filter, so I took that line off because the engine builder said I didn't need it, but that it went somewhere over there. So I don't know if that unoccupied nipple I mentioned on the previous paragraph is where the charcoal canister line goes to or if its for the unoccupied black hose pictured. Thanks for your help and please give me any sort of advice or knowledge that you have. This is where the area I'm talking about with the fuel leak is.  Here is a close up of the three nipples, with the top nipple unoccupied.  Here is the area for the hose going to nowhere.  Here is the hose itself.  And here is the line from the charcoal canister that I took off.  Heres my questions. 1) Are these two lines with the radiator clamps around them for fuel? 2) Is that third unoccupied nipple for fuel? 3) Does that black hose hanging connect to that unoccupied nipple? 4) Should fuel be coming from that black hose hanging there? 5) Where does the line coming from the charcoal canister connect to? |

|

|

|

|

|

#2 |

|

Rotary Fan in Training

Join Date: Mar 2011

Posts: 73

Rep Power: 15  |

The second picture shows the pressure and return lines for fuel going to and coming from the engine. They might leak fuel if it's a bad connection.

The nipple/pipe not connected to anything is a crankcase vent line that gets tied to the charcoal canister by a hose that is connected to a hard line clamped to the firewall. Sorry, I've never seen fuel dripping from the hardline coming from the charcoal canister...ever. Then again I've never looked . There's another hardline that goes to the charcoal canister that originates from the fuel tank three way checkvalve and THAT line might have some fuel in it but in tiny amounts. see jpg attached. Last edited by FRED; 04-14-2011 at 07:00 AM. |

|

|

|

|

|

#3 |

|

Rotary Fan in Training

Join Date: Mar 2011

Posts: 73

Rep Power: 15  |

There should be two HARDLINES clamped to the firewall going from the charcoal canister area to the area on the left side of the engine bay. One goes to the three way checkvalve back at the fuel tank and the other larger one goes to the crankcase vent line shown in your picture with the two fuel lines (ones with *radiator* clamps on them.

I'm not sure where the HOSE in your pictures is coming from. If coming from a hardline clamped to the firewall and that hardline is going over to the charcoal canister area, then that hose or a hose like it should go to the open hardline in your second picture. See the jpg I attached earlier. The hardline connected to nothing in your second picutre ...........if you follow it back to its original starting point on the engine, you'd find it gets tied to a nipple coming from the intermediate housing located just below the oil filler pipe. Real hard to see even when you know where it is when looking at a fully built up engine. Last edited by FRED; 04-14-2011 at 06:58 AM. |

|

|

|

|

|

#4 |

|

Rotary Fan in Training

Join Date: Mar 2011

Posts: 73

Rep Power: 15  |

If the hose in the attached jpg is clamped to a hardline passing from there over to the charcoal canister area, then yes, that line/hose should be connected to the open hardline in your second picture (the pic with the two hoses with band clamps and one open hardline).

|

|

|

|

|

|

#5 |

|

Lifetime Rotorhead

Join Date: Apr 2010

Location: Elkton, MD

Posts: 874

Rep Power: 16  |

Answers:

1. Both of those lines with the worm gear clamps are fuel. One of them (forget which - consult FSM or just follow the hose to figure it out) connects to the outlet of the fuel filter, and sees high pressure from the pump. The other is the return fuel line back to the tank. Get rid of those crappy worm gear clamps ASAP and get the proper clamps for fuel injection plumbing - the spring OEM type or the T-bolt style band clamps that are rated for this. Ditto for the hose - you'll also want to check the hose to verify that it is rated for high pressure fuel injection systems, not the cheaper fuel line hose that you can use on carb cars. 2. No, but that 3rd open nipple is for fuel vapors. Per the FSM, for a S5 turbo this one routes back to the charcoal canister. 3. I really can't tell from the picture, but on my S5 T2, that 3rd open nipple (discussed in #2 above) connects to a hose, which routes to another hardline nipple on the firewall, and that hardline routes across the FW to near the charcoal canister, where it connects to the canister with another hose. 4. Nope, just fuel vapors. 5. There are 2 nipples on the canister - you'll need to consult the FSM to determine which one goes where, but one of the nipples on the canister goes as discussed in #2 & 3, the other line goes back to the fuel tank, via hose & hard line. |

|

|

|

|

|

#6 |

|

The Newbie

Join Date: Jul 2010

Posts: 14

Rep Power: 0  |

Wow I really can't thank you two enough. I'll connect the hardline from the charcoal canister back onto that third nipple and then I'll trace the black hose to see where its coming from, however I'm not sure as to where its supposed to go. I know for sure its not coming from the charcoal canister. I thought it came from the rats nest near the intermediate housing, but where is it supposed to attach to?

|

|

|

|

|

|

#7 |

|

Test Whore - Admin

Join Date: Mar 2008

Location: Right Behind you son

Posts: 4,581

Rep Power: 10  |

There is a purge valve that allows some vapors to be sucked back into the UIM to be burned..... at least in the n/a world that I know so well.

Check the hose itself to make sure that it is rated for EFI, that would be my first guess, and that it was replaced. Once hose takes a set, gets hard and is reused, it tends to want to leak.... alot. Which shop and where are you located. There is a place local to me called "The Shop" so I'm a little curious as to who did the work

__________________

-The Angry Stig- DGRR 2009, 2011, 2012 & 2013 - Best FC DEALS GAP!! WOOHOOOO!!!!! 2015 Audi S4 - Samantha - Zero Brap S4 2004 RX8 - Jocelyn - 196rwhp, 19mpg fuel to noise converter 2000 Jeep Cherokee Sport - Wifey mobile - Now with 2.5" OME lift and 30" BFG AT KO's! So it begins 1998 Jeep Cherokee - 5 spd, 4" lift, 33" BFG's - Rotary Tow Vehicle 1988 'Vert - In progress 1988 FC Coupe - Gretchen -The attention whore BEAST! I'm a sick individual, what's wrong with you? I'm pure Evil I'm still insane, in the best possible way. I think Brian's idea of romance is using lube. Your rage caused the meteor strike in Russia. The Antichrist would be proud of his minion. You win with your thread. Most everything It's a truck with a steel gate on the back. Just a statement of fact Motec M820, AIM dash, ported 13B-RE Cosmo, 6-spd trans, 4.3 Torsen, custom twin wg fully divided mani, Custom 4" split into 2x 3" exhaust, Custom HMIC, Custom custom custom custom I like to welder stuff.... No Bolt-ons allowed. Dyno'ed @ Speed1 Tuned by me - 405rwhp on WG.... WM50 cuming soon. -Angry Motherf*cker Mode ENGAGED- |

|

|

|

|

|

#8 | ||

|

rotors excite me

Join Date: Mar 2008

Location: Iowa

Posts: 372

Rep Power: 18  |

Quote:

__________________

He isn't a killer. He just wins -- thoroughly.   '87 TII 240+ rwhp on my DIY streetport, ~13psi on stock turbo, Racing Beat REVTII exhaust  rTek 2.1 awaits a tune Quote:

|

||

|

|

|

|

|

#9 |

|

Rotary Fan in Training

Join Date: Mar 2011

Posts: 73

Rep Power: 15  |

I'll revise my answer. Seems the vent at the bottom of the filller neck goes to the purge valve. There is another hardline under there that is spliced to the line that goes to the top nipple on the filler neck.

The HOSE at the top of the filler neck goes to a hardline. That hard line splits off and one end goes to the turbo inlet duct on the other side of the engine. The other split goes aft to that open hardline nipple you showed along with the two fuel lines with the worm clamps. Sorta stare at the jpg out of the FSM and I'm sure you'll figure it out. Maybe that HOSE you see open goes to the bottom of the Purge valve????? Last edited by FRED; 04-16-2011 at 08:47 AM. |

|

|

|

|

|

#10 | ||

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Quote:

(see 1st / left pic below) Since these clamps are pretty small and the threads on the screw / bolt are pretty small, they are very easy to overtighten. Once you overtighten, the clamp is damaged and no good. Once the clamp is damaged, it will loosen and cause a fuel leak. If you know what you are doing and torque them properly, yes, they are superior versus the typical "worm gear pipe clamps" (see 2nd / right pic below) These worm gear pipe clamps are more resistant to overtightening and are superior than the above when overtightened - at least they will not back off and loosen. (I've had a customer of mine go through this headache a few weeks ago - "t-bolt" clamp leaked [most likely overtightened] and replaced with small "worm drive" pipe clamps.) If all of that scares you, use the stock-type spring clamps. I'd recommend to double them up though - that will guarantee it will not leak. Notice that the stock spring clamps use on the fuel system (if you got the originals) are thicker and "double walled" than the other clamps used on the emissions system plumbing. Quote:

(SAE) 30R7 / J30R7 - this is NOT what you want: http://www.discounthydraulichose.com.../30r7-hose.htm (SAE) 30R9 / J30R9 - this is the fuel injection rated stuff you want: http://www.goodyearep.com/ProductsDetail.aspx?id=5144 The key is the "7" versus "9" in the SAE code #. I've seen 30R7 with printed "RATED TO 150PSI" on the hose that failed on fuel injection applications. Ignore the "RATED TO" # - this doesn't mean squat in our case. (Notice the "Minimum Burst Pressure" rating of "250 psi" in the first link.) Steady state pressure does not cause the (30R7) hose to fail - it's the pulsation from fuel injection systems that does the damage. 30R7 is not designed to handle the pulsations and pressure fluctuations due to the fuel injectors firing rapidly. -Ted |

||

|

|

|

|

|

#11 |

|

The Newbie

Join Date: Jul 2010

Posts: 14

Rep Power: 0  |

^ This is all great stuff, I'm learning way more than I intended to from this thread.

I'll replace those worm gears, check the fuel lines to ensure they're the right ones, and take a look at the engine bay. I understand the hardline coming from the charcoal canister connecting to my unoccupied nipple, and I'll see if I can spot another unoccupied nipple where that other black hose may go to. Its definitely originating from underneath a section of the rats nest, connecting to what I think is a nipple on the intermediate housing, facing towards the front of the car. Seriously, thank you everyone. TTT, the shop that did my engine swap and rebuild is called Lucky 7 Racing in Duarte, CA, about 30 minutes from downtown Los Angeles. |

|

|

|

|

|

#12 |

|

Rotary Fan in Training

Join Date: Mar 2011

Posts: 73

Rep Power: 15  |

The PURGE valve is on the vacuum rack and is plastic. It has one small vacuum hose on top and two plastic nipples on its bottom. ONE is larger than the other and THAT might be where your open HOSE should go to. The PRUGE valve is to the rear of where the oil fillter tube is or.......on the rear half of the vacuum rack.

Purge valve looks like the one shown in the online factory service manual in the section Fuel and Emissions. I think I can spot it in one of your pictures just infront of the Blue duct going to the intake elbow. Black..........plastic. OR they might have removed the Purge valve in order to install that aftermarket intake duct......then there'd be no place for the hose coming from the oil filler neck to the purge valve. Last edited by FRED; 04-17-2011 at 01:48 AM. |

|

|

|

|

|

#13 |

|

The Newbie

Join Date: Jul 2010

Posts: 14

Rep Power: 0  |

^ That is the purge valve small vacuum line going over the top of the oil filler neck. I definitely still have it and only recall there being one hose attached to the bottom. That may be where it goes, thanks! I'll check tomorrow morning when its light out.

|

|

|

|

|

|

#14 |

|

The Newbie

Join Date: Jul 2010

Posts: 14

Rep Power: 0  |

Thanks again guys, looks like this issue got solved due to you all. FRED, that purge valve is exactly where my black line thats been hanging by the oil filter looks like it goes. I didn't realize the purge valve has two lines going into the bottom of it with only 1 vacuum line coming out the top.

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|