|

|||||||

| Rotary Tech - General Rotary Engine related tech section.. Tech section for general Rotary Engine... This includes, building 12As, 13Bs, 20Bs, Renesis, etc... |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| Rotary Tech - General Rotary Engine related tech section.. Tech section for general Rotary Engine... This includes, building 12As, 13Bs, 20Bs, Renesis, etc... |

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

KTEC

Join Date: Jan 2009

Posts: 642

Rep Power: 0  |

Direct Compressor Injection? Water/Meth

I have a new idea for where to inject. Or at least I haven't seen it done before, but maybe it has....? That's what I hope to find out.

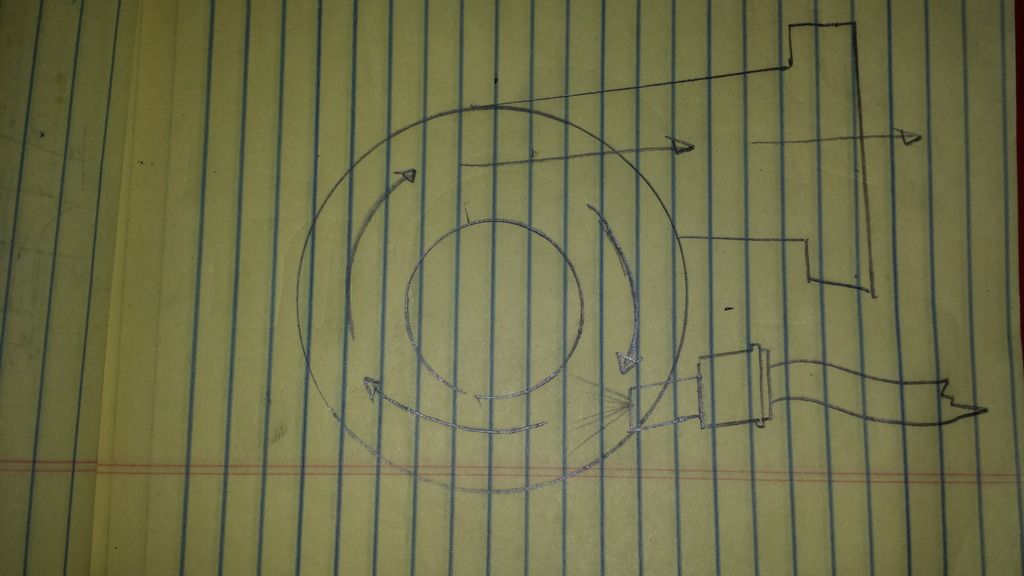

So basically I love the benefits of pre-turbo. And I also have had great results of post turbo closer to the TB. I'm running a pre turbo and post turbo with no intercooler right now... But I thought about placing a nozzle directly in the compressor housing spraying in the same path of the blades and air. The basic picture will give you a better idea of what I mean. This is neither pre or post turbo. This is direct injection for the compressor housing. Keeping the compressing air cool allowing more air to be compressed in the housing. Allowing the turbo to act as a larger frame turbo possibly better than pre turbo. It will also be flowing directly with the flow of moving air and the blades cutting down on the chances of cendensation building up on the turbo inlet, misaligned nozzle, and various other problems spraying a mist at a spinning wall of blades causes. I have "theories" on why this would work great. But no real data. Plus... what the fuck do I know? Lol...

__________________

what I have: 1985 Gs:12a All motor Drag car - 1973 Rx2: Play car What I had: 93 Touring: TRADED - 91 Coupe: TRADED - 90 GTU: RHD - 88 10AE: SOLD - 87 Base: SOLD - 86 Base: SOLD - 1985 GSLSE - 85 Gsl: SOLD - 80 Gs: TRADED - 1972 Rx2 |

|

|

|

|

#2 |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 18  |

Something different.

I have no idea but you would loose some of the mass flow increase going in through the front. Some of the air restricted rally cars I have done (all illegal mind you!) tried something similar to what you draw here, but the get more net mass flow through the pre turbo restrictor it was giving more gains in power/tq when injected 'pre turbo' The more that test it the better, give it a go and let us know how you get on with it

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration |

|

|

|

|

#3 |

|

Rotary Fan in Training

Join Date: Apr 2012

Location: NSW, Australia

Posts: 39

Rep Power: 0  |

Edited for the I don't know how manyth time with further detail.

I believe the "lower expelled volume" idea you are thinking of is best served by pre-compressor injection anyway as the fluid will absorb most heat energy and reduce gas expansion most if it is present from the compressor inlet. That really won't make a difference in terms of maximum compressor flow, if you are running to choke to have the most flexible engine package possible. Max compressor flow is when the intake air at the compressor inducer reaches the speed of sound, your model does nothing to increase the density of the charge air at the compressor inducer (see different trim specs of same OD compressor wheel in GT catalog as proof of the "tight spot", larger inducer=more flow on same wheel, albeit generally with efficiency sacrifice). As you have drawn above assuming the interaction is actually after the maximum radius of the compressor then it is entirely post compressor/tion injection, if you are running a high pressure injection half way across the compressor blades I'm pretty sure you will cut them up. You want minimum pressure drop across your filter and the most reduction in temp you can achieve into the compressor, airbox/filter not fed from behind the radiator like so many people do Also, unless your compressor outlet temps are already at or below ambient (I very much doubt that) you will also never achieve the system efficiency you could by running an intercooler, you simply cannot move the same air mass without more required turbine energy, which is lost crank power. Basically if you are going to have two point AI, for best effect you want one pre-compressor (with decent flash volume) and one post intercooler to get maximum system efficiency. If you refuse to run/can't package an intercooler, stick with 2 point, one pre-compressor, and if not using an intercooler, that compressor housing injection obviously gives the longest flash time/largest flash volume before the intake ports. Last edited by Slides; 05-05-2015 at 12:48 AM. |

|

|

|

| Bookmarks |

|

|