Build threads are not really my thing since they consume a bunch of time and stuff like that (Which I never seem to have enough of). But I said I would so here it is for those who may or may not care.

Quick recap of the last few years.

Had some FBs with 12As and 13Bs

Didn't really like FC chassis for whatever reason. I honestly can't even remember why since I love this chassis now.

Bought an NA FC to daily drive. 89 GTU.

Did that for a bit, fixed minor stuff on it, made a proper road car out of it and all that.

Got into drifting. Decided the FC was better for drifting than a FB, not for any fault of the FB but for the "off the shelf availability of parts". Coilovers are cheap and fenders and that sort of stuff.

Built a decent drift/street car based off my NA S5 engine. Racing Beat road race exhaust, streetported, and a bunch of other stuff. Made approx 200hp at the flywheel probably. Nothing spectacular. Faster than a RX-8, so whatever amount of power that takes. Other stuff like the T2 rear end and delrin bushings throughout the car from MMR. BC Racing coilovers, knuckles, the usual stuff that ends up in these cars.

I used the car for a bit of advertising for my company that is now closed due to lack of customer participation shall we say (Rotary Related). Still got to build dozens of cool cars and stuff. Had a lot of fun, made some money. Nothing crazy though.

Had fun drifting it this season. It does quite well. here's a vid of the car through most of the events I attended in 2012. Some events aren't in the video, but who cares.

http://vimeo.com/51454673

Anyways

The car was good enough to have some fun and link most of the tracks no matter how big the entries and all that were. Mostly it would be on 205s in the rear and would almost have to be brand new tires to have the compromise between off throttle grip and being able to break the tires lose. Sometimes very frustrating to drive.

Driving the car like this was a "one shot deal". you run the perfect line and do everything correctly and you look good and have fun. If you don't then you fail miserably and there's no coming back from a decent sized mistake, due to the fact the car just didn't make enough power.

I drove my buddies SBC FC somewhere at the beginning of the year. At the time I drove it, it was not well setup and the engine had some issues. It still had more power than was necessary and I enjoyed the five or so laps I took in it. So easy to drive and gave you the freedom to roam around outside the line with no issues such as not having enough power to connect the next transition.

I then bought a 13BT, street ported it and painted it, bought a BNR turbo Stage 4 S5 jam), a bunch of supporting equipment. Spent maybe 3000 bucks in a couple weeks. Was all ready to make at least 300whp. It was going to be awesome.

Then that nagging feeling came back, about driving my buddies SBC FC..........oh that feeling.........the devil possibly, lol.

So I sold all my recently purchased 13BT stuff to a friend who is putting together a FC drift car locally here. I still get to finish that up with him, and drive it and all that, so I feel I've won on both accounts.

I wanted to make a purchase to lock myself into the swap. So i sold my S5 drivetrain to another friend locally so he could put it in his AE86, since the 4AGE sucks. We swapped it in, super easy to do btw. Using a GSL-SE transmission it fits quite well. Here's a vid of that car........just has coilovers and factory steering capability. Not bad for the shakedown of this thing. Also my Buddies SBC FC is in this video as well. He has no front end because he's lazy and didn't want to reassemble it before the event.

http://vimeo.com/51958204

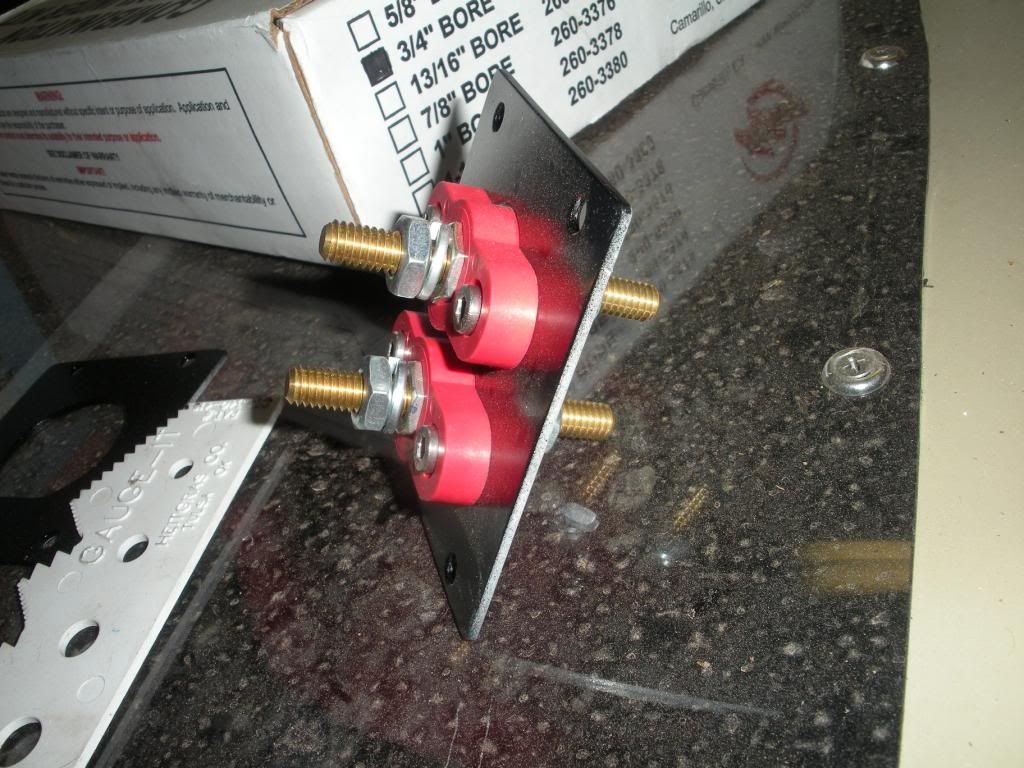

So after I sold that stuff to my buddy with the AE86 I bought the Granny speed shop small block Chevy mount kit (Locked in). You can mount LT engine's as well with this kit. Actually he just came out with adapters for the mounts to use the same kit to mount LS engines as well.

Now your mostly caught up.

No I don't care if someone doesn't like V8s in RX chassis, don't even bother arguing I'll just ignore you. I'm doing it for me and only me. Just about the only kind of engine I have not owned in any of my previous cars is a V8. I have gone back and forth with myself on this for over a year now. Then I finally decided "Fuck it I want it!" .......that is all. I may or may not have said 'Merica!

I'll add some pics and what not pretty quick here of the actual build.

Hybrid Mode

Hybrid Mode