|

|||||||

| Show your rotary car build up. Show off your Rotary Car build! |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| Show your rotary car build up. Show off your Rotary Car build! |

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

Rotary Fan in Training

Join Date: Feb 2009

Posts: 69

Rep Power: 17  |

Redhead FC project

Well, i figured i'd start a project thread in the right place. I picked up a 87 N/A FC last spring for a trifling $300. Its a South Carolina car and is virtually rust free. Aside from some major and minor issues, the car seems to be in OK shape. I have the typical leaking sunroof along with a semi-dead motor. This is also my first rotary car/rebuild

The motor will start right up and run, but its eating oil and coolant like a kid eating PEZ. 1/2 a quart of oil in 30 minutes and its a mosquito fogger with the coolant its burning. Interior is a little rough, cracked vents, a little dirty and the shifter boots need replaced. It also has a dent/scrape on the quarter panel/door but that is minor. The plan at the moment is to secure a used S5 N/A motor and do a hybrid build consisting of: S5 rotors/c-weights S5 Intake S4 front cover (to retain mechanical MOP) Ported 6-port irons w/ pineapple inserts S5 trans EGR Blockoff Not sure on the rebuild kit yet, possibly going to go atkins with cryo treated apex, solid corner and side seals. Second phase after getting the rebuild running and broken in on stock S4 electronics will most likely be a Megasquirt ECU. Not sure if this is going to be the PnP MS (based on the MS-II Extra Microsquirt) or the MS-III (if its out of beta by the time im done) I have some questions regarding ideas i have for the build. 1) is bridgeporting the aux ports worth the time? 2) What RPM should i limit the motor to after the porting and rotor swap? 3) Is there anything else that can be done to the motor that would be beneficial in a pre-mild turbo build? (retaining S5 rotors on said turbo build) 4) with a header and cat-back exhaust, is there enough pressure to actuate the 5th and 6th ports or do i have to run an electrical or air pump based alternate method? 5) Is there an LSD that fits the N/A rear end? or is the LSD limited to the T-II?? In addition, there are some parts that i will be in the market for used or new (will update as needed  ) )1) pineapple 6-port porting template 2) header and cat-back exhaust for an N/A 6-port motor 3) Flywheel stop Advice, input and suggestions welcome and encouraged Last edited by Shadow24v; 01-04-2010 at 02:48 PM. |

|

|

|

|

|

#2 | |

|

Blue Blur

Join Date: Jan 2009

Location: Windsor

Posts: 211

Rep Power: 0  |

Quote:

2) Dont know 3) Dont know 4) Any change to stock exhaust will require one of the 2 mods, mostly like the stock exhaust isnt actuating them anymore 5) There are a couple of aftermarket lsd's that will fit, or you could find someone selling the rear out of a gxl model car they have an lsd also that will fit in any na. |

|

|

|

|

|

|

#3 |

|

Rotary Fan in Training

Join Date: Feb 2009

Posts: 69

Rep Power: 17  |

Ok, so the streetport template is about the best you can get without adversely affecting idle and drive-ability? I guess that makes sense

Regarding the exhaust - i sorta thought an aftermarket would require alternate methods of aux port actuation. thanks for the confirmation Hmm, i'll have to look around at the GXL option then. thanks

|

|

|

|

|

|

#4 |

|

Can't.Make.Up.My.Mind.

Join Date: May 2009

Location: Murfreesboro, TN

Posts: 1,377

Rep Power: 18  |

just wire your ports open. thats what i did on my na

__________________

'90 GTUs Stay up to date with my photography '06 Toyota Highlander Hybrid '10 Toyota Prius "Initial Success or Total Failure" |

|

|

|

|

|

#5 |

|

Rotary Fanatic

Join Date: Sep 2008

Posts: 147

Rep Power: 18  |

I would remove the 5 & 6 port sleeves entirely, and use some JB weld or similar to build a "ramp" for the air entering the ports, so it's not such a right angle turn entering the chamber. (Like these, but in the port itself instead of the sleeve: http://www.pineappleracing.com/6-por...sertspair.aspx)

I've done this to very good effect on a similar hybrid motor, a GSL-SE 6 port with S5 NA rotors & weights. |

|

|

|

|

|

#6 |

|

RCC Addict

Join Date: Feb 2008

Location: VA

Posts: 1,812

Rep Power: 19  |

Lots of JB weld in the intake --- no thanks.... I'd keep the sleeves in and use the inserts. Those sleeves do help bottom end and fuel mixtures entering the combustion chamber. Its not hard to get to them and clean 'em and once functioning correctly, they're nice to have in an NA car....

|

|

|

|

|

|

#7 | |||||||

|

Test Whore - Admin

Join Date: Mar 2008

Location: Right Behind you son

Posts: 4,581

Rep Power: 10  |

Quote:

Quote:

Quote:

Quote:

Quote:

Quote:

Quote:

__________________

-The Angry Stig- DGRR 2009, 2011, 2012 & 2013 - Best FC DEALS GAP!! WOOHOOOO!!!!! 2015 Audi S4 - Samantha - Zero Brap S4 2004 RX8 - Jocelyn - 196rwhp, 19mpg fuel to noise converter 2000 Jeep Cherokee Sport - Wifey mobile - Now with 2.5" OME lift and 30" BFG AT KO's! So it begins 1998 Jeep Cherokee - 5 spd, 4" lift, 33" BFG's - Rotary Tow Vehicle 1988 'Vert - In progress 1988 FC Coupe - Gretchen -The attention whore BEAST! I'm a sick individual, what's wrong with you? I'm pure Evil I'm still insane, in the best possible way. I think Brian's idea of romance is using lube. Your rage caused the meteor strike in Russia. The Antichrist would be proud of his minion. You win with your thread. Most everything It's a truck with a steel gate on the back. Just a statement of fact Motec M820, AIM dash, ported 13B-RE Cosmo, 6-spd trans, 4.3 Torsen, custom twin wg fully divided mani, Custom 4" split into 2x 3" exhaust, Custom HMIC, Custom custom custom custom I like to welder stuff.... No Bolt-ons allowed. Dyno'ed @ Speed1 Tuned by me - 405rwhp on WG.... WM50 cuming soon. -Angry Motherf*cker Mode ENGAGED- |

|||||||

|

|

|

|

|

#8 |

|

Rotary Fan in Training

Join Date: Feb 2009

Posts: 69

Rep Power: 17  |

Titanium -

I was planning on keeping the aux sleeves anyways. everything i read said that they are a good thing to keep on an N/A build. Regarding the MS, I have already built and tuned an MS-II v3.0 running the MS-II Extra code for my DD car (92 Sundance Duster with an 01 eclipse v6 running EDIS,mid to high 20s mpg mixed driving, close to or above 30mpg if i blow the whole tank on the highway and ~200ish WHP, 14.712@92.99mph with a crappy 2.1 60') Why would brigeporting the Aux ports hurt daily driving? don't they open at 4000+rpms? I was thinking a bridge on the aux ports for higher RPM flow while retaining a streetport on the primary and secondary ports... Also, would running a 4-port center housing for larger primaries adversely affect low end power? Balancing is being figured in to the build due to the mix-and-match nature of the motor a Miata diff will fit the N/A rear end and axles? that makes life simpler

|

|

|

|

|

|

#9 |

|

Rotary Fan in Training

Join Date: Aug 2008

Location: Goose Creek/Summerville

Posts: 60

Rep Power: 18  |

about the aux bridge lisin to TitaniumTT I beleive it was one of the many things me and him bumped heads over but hes right. also on my current car the aux ports open at ~3200rpm.

As For MS the volvo guys swear by them.(745T owner) now you could setup and electric actuator(thinking window motor rod setup keep the motor and survo away from the exhast), and RPM switch so you could set the RPM you want your AUX ports to kick in. if porting i think a large streetport on you aux ports and a mild streetport on your mains might work better then a full aux bridgeport.

__________________

2000 Acura Integra GS: daily driver 1990 Mazda RX-7 GTU: parts car. 1986 Mazda RX-7 base: under the knife.(no sunroof!!!) 1989 Volvo 745 turbo: B230ET,19T turbo,850 Turbo injectors,HKS Manual Boost Controler,Port/Polish,Oversized valves,titanium valve springs,M-Cam,G80 locker,modded AW71 transmission. |

|

|

|

|

|

#10 |

|

Rotary Fan in Training

Join Date: Feb 2009

Posts: 69

Rep Power: 17  |

south - thanks for the input.

I was thinking of one of the programmable MS outputs to trip a relay for the actuators, but not sure how that would work out just yet. i was looking at the Pineapple 6-port template for use on my motor build. I'm wondering if there's more room on the aux ports for a slightly larger port with that template or not *shrug* Good point on the aux bridgeport. I want to keep this DD-able so i'll stick with the "streetport" approach (which should help when the turbo gets added later  ) )

|

|

|

|

|

|

#11 |

|

Rotary Fan in Training

Join Date: Feb 2009

Posts: 69

Rep Power: 17  |

|

|

|

|

|

|

#12 |

|

Rotary Fan in Training

Join Date: Feb 2009

Posts: 69

Rep Power: 17  |

Well, got to spend 3 days with the 7 this weekend. Got the motor pulled and almost ready to tear apart. Had to "persuade" the crank bolt to loosen up (3' breaker bar and a jammed flywheel works

) and the flywheel nut needed a 5'-6' pope on a breaker bar + gravity to finally pop it loose. ) and the flywheel nut needed a 5'-6' pope on a breaker bar + gravity to finally pop it loose. It looks like the rear seal was leaking and i found a piece of metal embedded in the flywheel side of the clutch. Also looks like the PP/FW have some discoloration to them. Can the stock flywheel be resurfaced? I'm thinking about seeing how much a rebuild kit for the trans will cost or whether to look into the miata gear set swap. Hoping to find out soon what the motor is hiding inside. (good compression but coolant/oil consumption) Any input or observations welcome  On the lookout for S5 N/A rotors/counterweights and VDI intake as the S5 motor i had lined up fell through

|

|

|

|

|

|

#13 |

|

Can't.Make.Up.My.Mind.

Join Date: May 2009

Location: Murfreesboro, TN

Posts: 1,377

Rep Power: 18  |

so then im assuming that the torsen lsd from the miata is handling 400+ rwhp then titanium? thats good to know.... hmmmmm.... i like forums....

__________________

'90 GTUs Stay up to date with my photography '06 Toyota Highlander Hybrid '10 Toyota Prius "Initial Success or Total Failure" |

|

|

|

|

|

#14 |

|

Rotary Fan in Training

Join Date: Feb 2009

Posts: 69

Rep Power: 17  |

Got the ports back from hot tanking and made some interesting discoveries: the motor has been rebuilt before. The crank pulley bolt was lathered in blue loctite and the center iron is DEFINITELY newer than the front and rear irons. I measured the wear on the irons and the center and rear irons only came up with .002-.003 step wear max. the front iron came up with .004 step wear

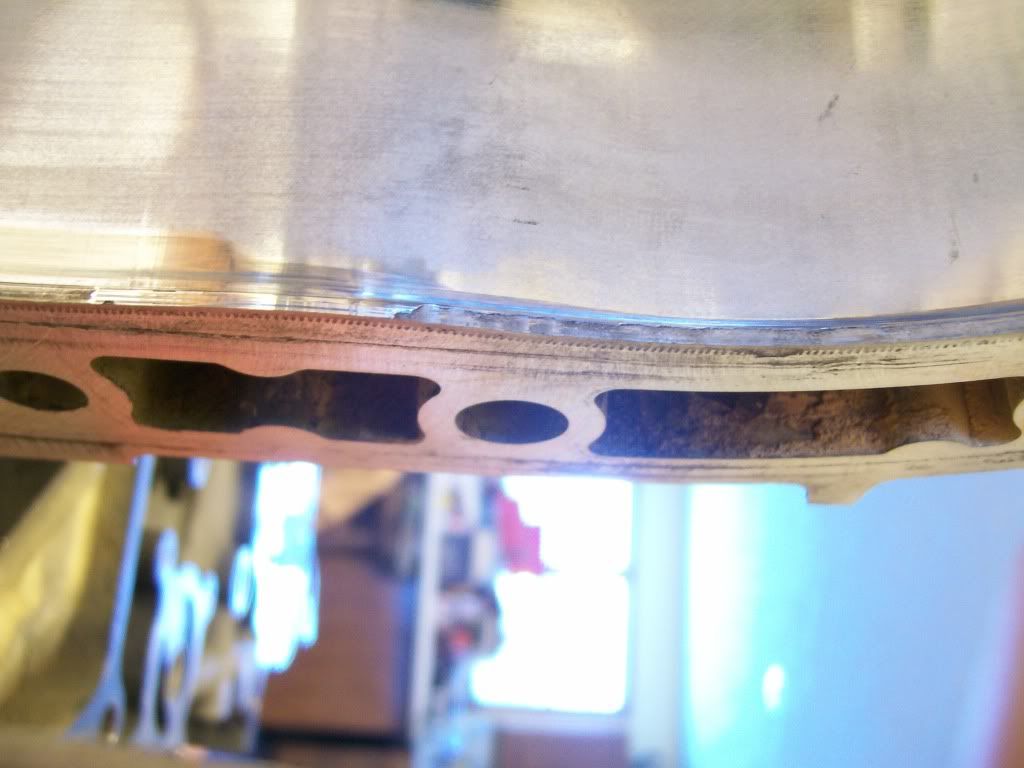

Is this beyond the limitations of lapping? How much can you take off the irons with lapping and still be OK? If they aren't able to be lapped due to wear, i am working on a deal for an S5 long block to use so hopefully i can use those parts... Is this beyond the limitations of lapping? How much can you take off the irons with lapping and still be OK? If they aren't able to be lapped due to wear, i am working on a deal for an S5 long block to use so hopefully i can use those parts...the rotors also seem to have a lip of sorts on the back part of the apex seal groove. Is this normal wear? the apex clearances were in spec before the rotors were totally pulled apart. Also, can you lap the housings to eliminate pitting around the water seals? (if you look at the pics, i doubt my housings are useable anyways...) Rear Iron (notice how rusted the hose nipples are)    Center Iron (notice how new and fresh the nipples are and the general condition of the iron)   Center vs rear  Front Iron (worst step wear of .004)   Front vs center

|

|

|

|

|

|

#15 |

|

Rotary Fan in Training

Join Date: Feb 2009

Posts: 69

Rep Power: 17  |

Rotors (lip edge and weights)

Lip i mentioned before  Rear rotor  Front rotor  Rear housing (im gonna guess bad wear but some input on the wear and wear patterns would be appreciated)           Front Housing (again, bad wear and im guessing an unusable housing  ) )

Last edited by Shadow24v; 03-01-2010 at 09:03 PM. |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|