Alright the parts I used are:

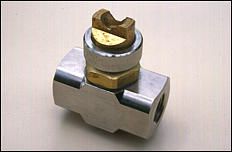

1)Atomizing nozzle from

http://www.spray.com/cat70/f/F16.html part number is sue18, in stock form it flows 380cc at 20psi. I started with it like this and a few months later drilled it out to flow 500cc at 20 psi, and close to 600 cc at 23 psi.

2)I have a well built polypropylene tank from US plastics almost a gallon in size.

3)An adjustable pressure switch purchased from a aux injection website.

4)A spare nitrous solenoid to cut water flow.

5)Various hoses.

Before ordering the poly tank I was concerned it wouldn't be able to hold the pressure, so I conducted a small test. The test involves an innocent mobile1 container, a tire valve, and an air compressor.

I drilled a hole in the cap and threaded a tire valve into it. I slowly increased the pressure checking each time with a tire gauge how much pressure was in the container. I got to 15 psi and took a 5 minute break to prepare myself for a loud BOOM, and maybe a slight bit of pain, as the container was definitely Ballooning. Once I got my shit together, I went ahead and upped the pressure up to 23 psi. Amazingly it held, I stopped there figuring that was enough to satisfy my curiosity. While it's not the same as the container I purchased, the plastic is much thinner with the mobile1, therefore if the cheap Mobile 1 plastic container held, I feel confident the one I got will hold even better. (which after 9 months it has proven its worth)

Here is a picture of the mobile1 container with 23 psi in it.

When I first hooked the water injection up, I used a clear poly irrigation hose. I wasn't sure how it would hold up against the heat, but no one in town had any silicone hose. I drilled and tapped the turbo for a hose barb fitting and ran a hose to the tank which was drilled and tapped on top and bottom. As it turned out the hose on the turbo didn't hold up, and I replaced it with a fuel injection hose. I also originally mounted the nozzle inside the air filter and had it pointed directly at the turbo. I had to weld a stainless steel bolt onto the back of the nozzle (see first pic below), drill a hole in the filter and bolt it to the filter. It worked extremely well like this, but I later decided to add a cold air intake to my turbo and had to remove the nozzle from the air filter and mount it to the side of the CAI.

I'll post the pics of how it was hooked up originally, then post how it's hooked up now while explaining the reasons for changes.

Pics of the system not installed, you can get an idea of the parts and basic system.