okay i dug out my Atkins manifold and gave it an overview.

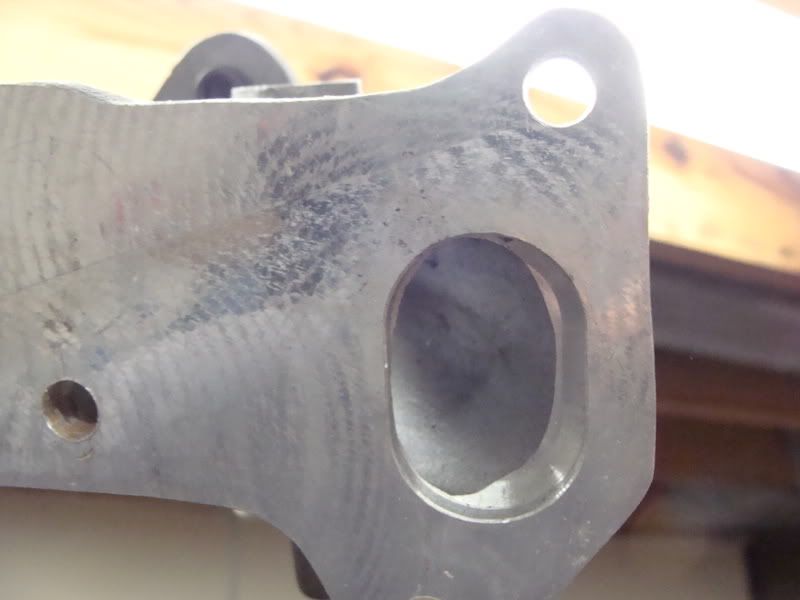

As you can see in the pictures below, the runners do need to be finished. The machining of the ports is direct cut inward but does not transition to the cast runners well. This is probably because its cheaper. Which, honestly, is fine by me. I would rather have to do a little touch up and spend less money. Plus you can still port match as needed. My engine is a stock port engine, so for now, there is really nothing to exotic to be worrying about.

You can also see that air entering the manfold has a very low restriction before it moves on into the runners. The inside is a smooth casting so there is nothing nearly as rough as anything oem. There is no fancy dynamic intake effect happening, but the air is also not forced on a elaborate path or into the walls of chambers. This will probably allow for a very good flow at high rpms. We shall see once i can strap the car to a dyno.

Also the concern that the air will have too great an angle to turn into the port on the iron really doesn't seem justified either. As you can see below, the top view shows the angle of the runners. For starters there is only one plane that isn't level, unlike the longer wrap around style. So the path the air is taking is only altered on a single dimension. Secondly, look at the picture and you can see how the center runners have approximately a 30 degree angle with the secondary ports having about a 45 degree angle. That is not to shabby in comparison to the wrap around which forces the air to make a sharper turn as it comes down, in order to center the port.