It was then time to address the half shafts.

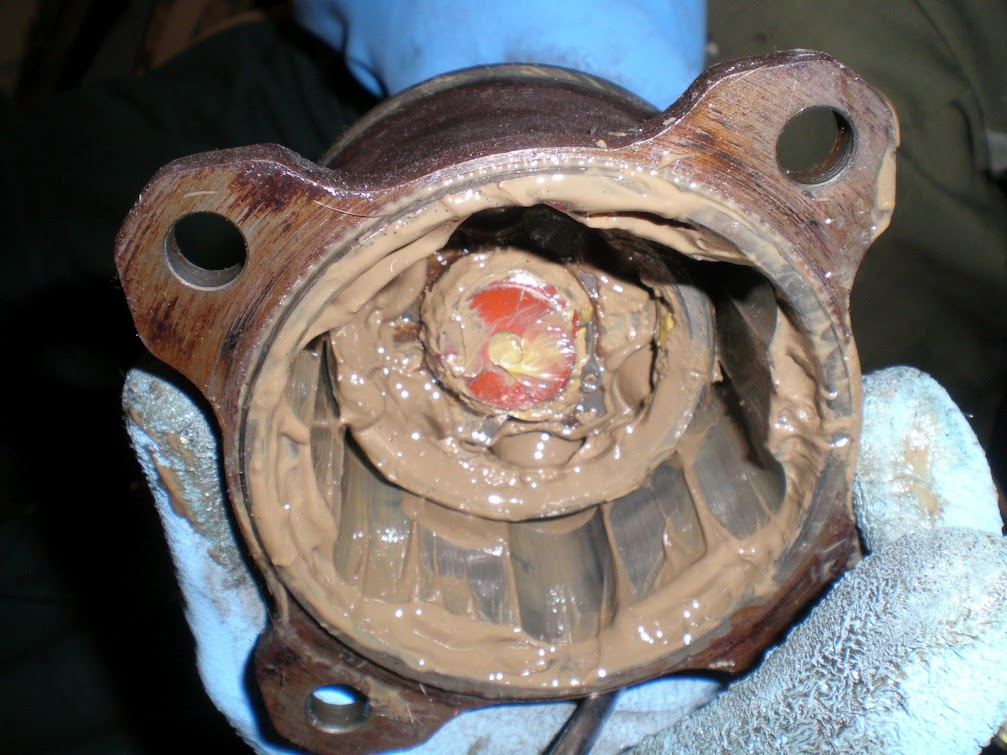

this was the driver side shaft where the end cap was forced out...who ordered the pudding?

Step One: dissasembly

Step One: dissasembly There is a circular retaining clip just under the inside lip of the cup. Simply pry that out with a pick or screwdriver...

and the shaft should slide right out , and drop nasty greasy balls in your lap....or onto your prepared work surface.

Step Two: Cleaning

Step Two: Cleaning I don't know the best substance to clean off old axle grease in 20 degree weather, but I know what it ISN'T....Acetone. That's all my buddy had, but I ended up resorting to dish soap and a pile of paper towels.

Step Three: Reassembly Now that everything is clean, time to dirty up again with fresh grease. I went with the heaviest synthetic import specific grease I could find at the parts store, I think it was made by valvoline.

Don't forget to re-install the retaining clip

This was my "solution" for that end cap that was forced out (because i couldn't source another cup and couldn't afford a new axle). The mating surface was coated with RTV, in retrospect perhaps jb weld would have been a better option....time will tell.

(Optional)

Step Four: Prep/ProtectionA little paint never hurt anybody...